Streetlamp maintenance mechanical arm device

A technology of mechanical arms and street lamps, applied in the direction of manipulators, lifting devices, claw arms, etc., can solve the problems of unfavorable automatic maintenance, increased maintenance workload, low degree of automation, etc., achieve efficient and fast maintenance, high promotion and application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

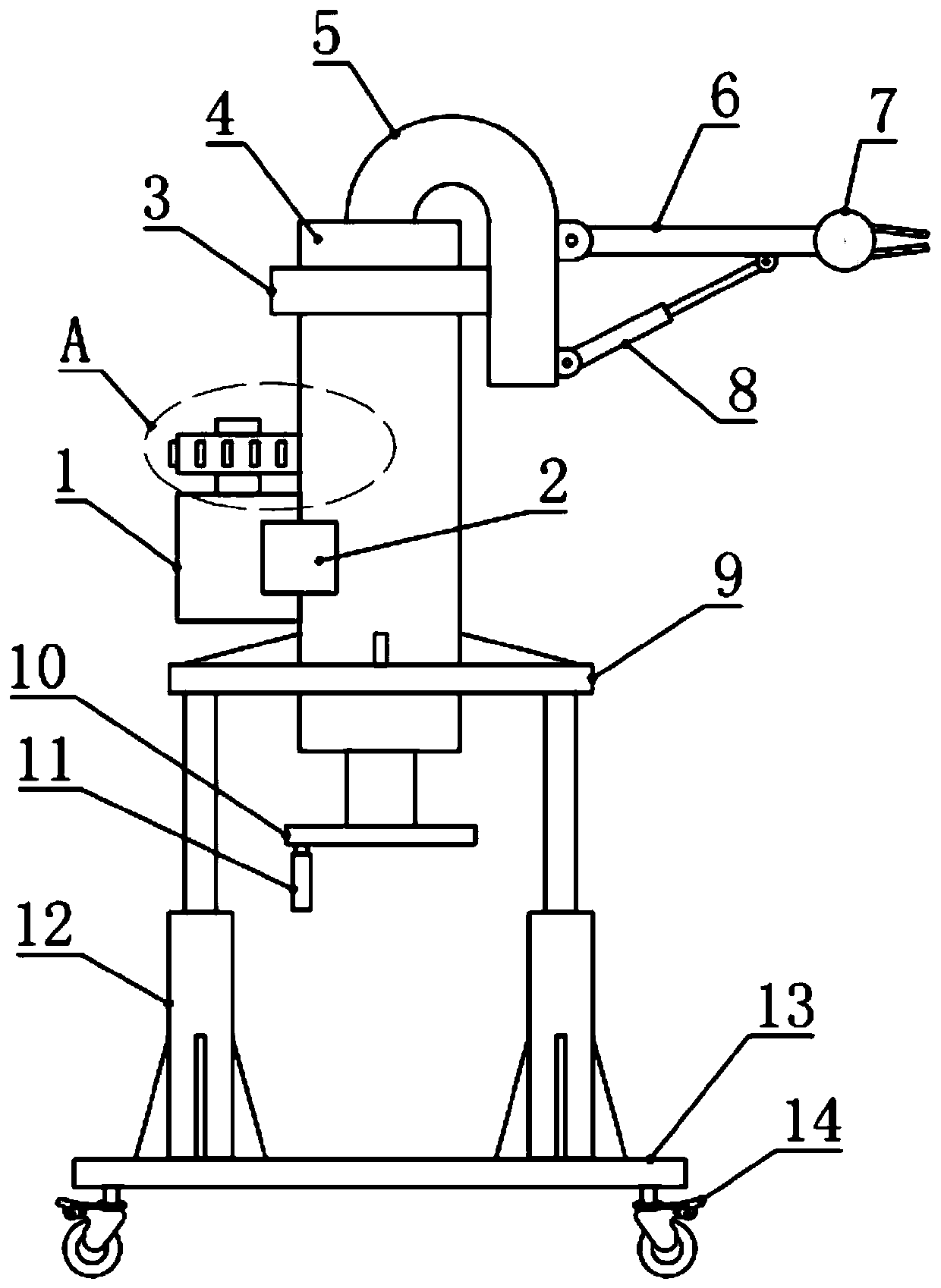

Embodiment 1

[0018] see figure 1 , in an embodiment of the present invention, a street lamp maintenance mechanical arm device, including a clamping manipulator 7 and a base plate base 13, a vertical tube 4 is mounted and fixed on the base plate base 13 through a lifting support assembly, and the vertical tube 4 is rotatably installed There is an inverted U-shaped rod 5, and the inverted U-shaped rod 5 is driven to rotate through a manual assembly or an electric assembly, and the vertical part of the inverted U-shaped rod 5 located outside the vertical tube 4 is also connected to the vertical tube 4 through the collar 3 Rotationally connected, the vertical part of the inverted U-shaped rod 5 located outside the vertical tube 4 is also equipped with an arm 6 and an angle-adjusting telescopic cylinder 8, and the angle-adjusting telescopic cylinder 8 is used to adjust the angle of the arm 6 As well as support, the end of the arm 6 is equipped with a clamping manipulator 7, and the clamping man...

Embodiment 2

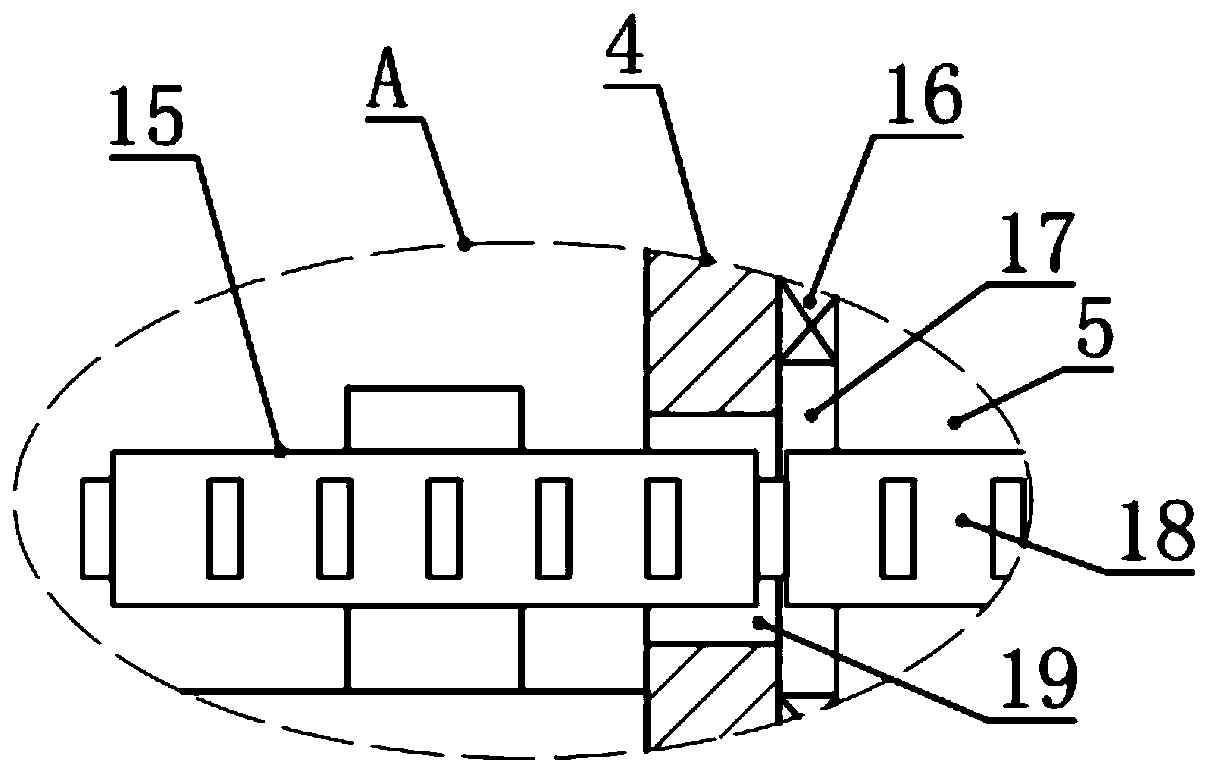

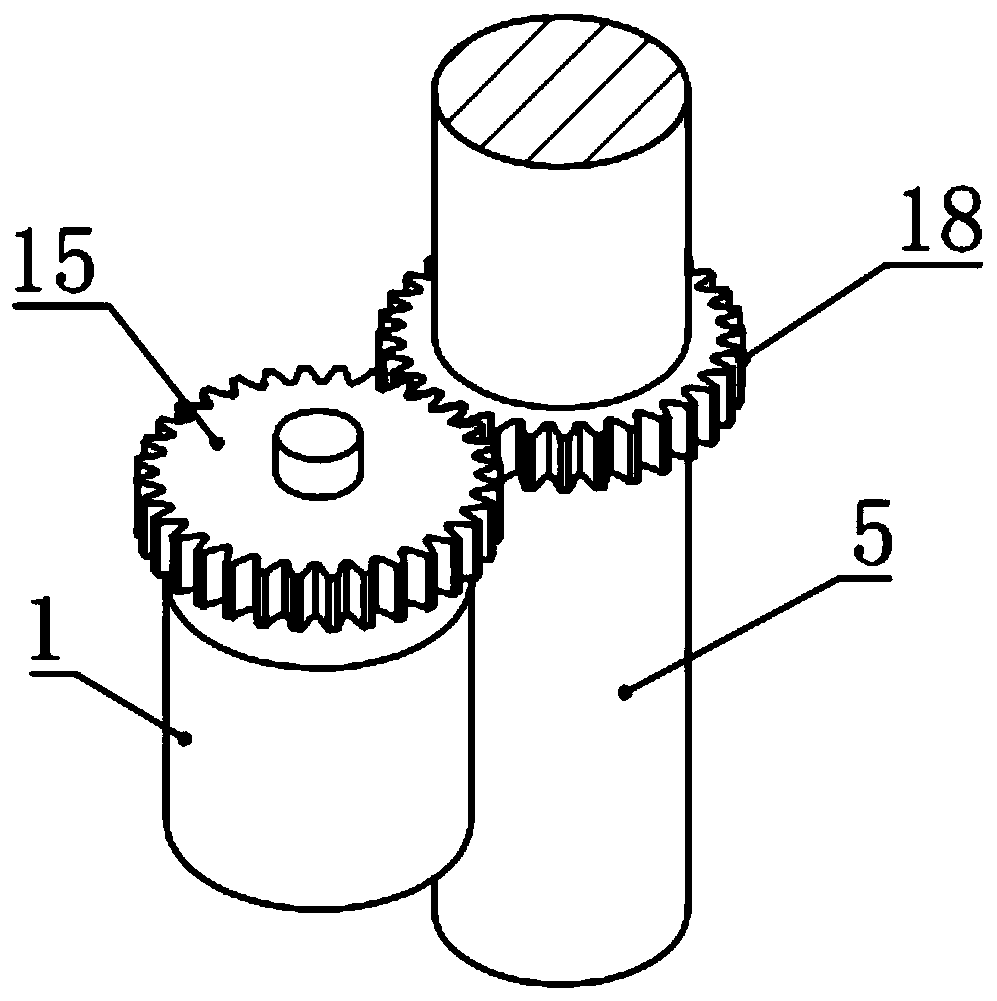

[0021] see Figure 1-3 , the difference between this embodiment and embodiment 1 is:

[0022] In this example, if figure 1 As shown, the lifting support assembly includes an installation ring plate 9 and a height-adjustable telescopic cylinder 12, the installation ring plate 9 is installed and fixed on the lower part of the vertical tube 4, and the lower side of the installation ring plate 9 is installed and fixed in a circumferential distribution. Adjust the height telescopic cylinder 12, the lower end of the height adjustment telescopic cylinder 12 is installed and fixed on the floor seat 13, and the vertical tube 4 can be supported and height adjusted by the cooperation of the height adjustment telescopic cylinder 12 and the installation ring plate 9; in order to facilitate the movement of the device, the The bottom of the floor base 13 is also provided with a plurality of universal wheels 14 with brakes distributed circumferentially.

[0023] In this example, if Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com