Phthalic anhydride polyester polyol with narrow molecular weight distribution, and preparation method thereof

A technology of phthalic anhydride polyester polyol and phthalic anhydride, applied in the field of polyester polyol, can solve the problems of wide molecular weight distribution, alkyd deviation, high loss, etc., and achieve the effects of narrow molecular weight distribution, excellent flame retardant performance, and low feed ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

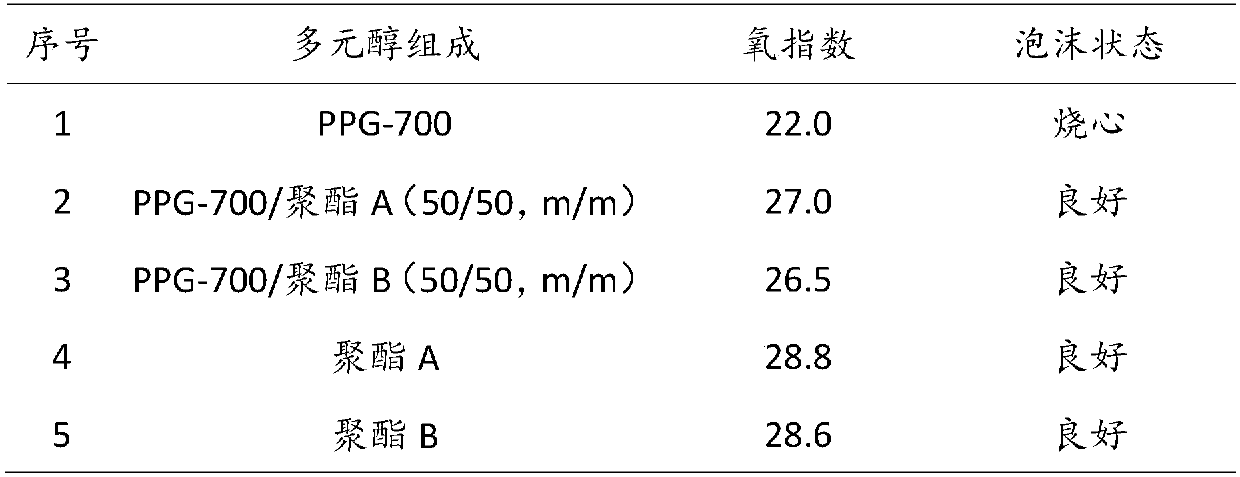

Examples

Embodiment 1

[0027] 10.0kg (67.6mol) of phthalic anhydride and 9.3kg (87.9mol) of ethylene glycol were successively added into a 25L reactor, and the molar ratio of alkyd to acid was 1.3:1. Under the condition of nitrogen protection, raise the temperature of the system to 160°C, and react at this temperature for 0.5h; raise the temperature of the system to 200°C within 1h, and react at this temperature for 1h; raise the temperature of the system within 1h Rise to 230°C, and monitor the acid value and hydroxyl value. When the acid value is lower than 20mgKOH / g, turn on the vacuum system, and the vacuum degree will slowly drop to -0.09MPa within 0.5h to remove the moisture and small molecule alcohol in the system. When the acid value is less than 2mgKOH / g and the hydroxyl value is 108-112mgKOH / g, the vacuum is stopped and the material is discharged. The obtained product is denoted as phthalic anhydride polyester polyol A.

[0028] Product index: acid value 0.8mgKOH / g, hydroxyl value 110.8mg...

Embodiment 2

[0030] 10.0kg (67.6mol) of phthalic anhydride and 9.3kg (87.9mol) of ethylene glycol were successively added into a 25L reactor, and the molar ratio of alkyd to acid was 1.3:1. Under the condition of nitrogen protection, raise the temperature of the system to 170°C, and react at this temperature for 0.5h; raise the temperature of the system to 210°C within 1h, and react at this temperature for 1h; raise the temperature of the system within 1h Raise to 230°C, and monitor the acid value and hydroxyl value, and turn on the vacuum system when the acid value is lower than 20mgKOH / g, and the vacuum degree will slowly drop to -0.09MPa within 0.5h, and remove the moisture and small molecule alcohol in the system. When the acid value is less than 2mgKOH / g and the hydroxyl value is 108-112mgKOH / g, the vacuum is stopped and the material is discharged. The obtained product is denoted as phthalic anhydride polyester polyol B.

[0031] Product index: acid value 0.6mgKOH / g, hydroxyl value 1...

Embodiment 3

[0033] 10.0kg (67.6mol) of phthalic anhydride and 9.3kg (87.9mol) of ethylene glycol were successively added into a 25L reactor, and the molar ratio of alkyd to acid was 1.3:1. Under the condition of nitrogen protection, the temperature of the system is raised to 160°C, and the temperature is kept at this temperature for 1 hour; the temperature of the system is raised to 200°C within 1 hour, and the temperature is kept at this temperature for 2 hours; to 230°C, and monitor the acid value and hydroxyl value, turn on the vacuum system when the acid value is lower than 20mgKOH / g, and slowly reduce the vacuum degree to -0.09MPa within 0.5h, remove the moisture and small molecule alcohol in the system, to When the acid value is less than 2mgKOH / g and the hydroxyl value is 108-112mgKOH / g, the vacuum is stopped and the material is discharged. The resulting product is denoted as phthalic anhydride polyester polyol C.

[0034] Product index: acid value 0.6mgKOH / g, hydroxyl value 110.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com