Stress-driven flexible terahertz dynamic control material and its preparation method

A terahertz, dynamic technology, applied in the field of dynamic regulation of terahertz waves, to achieve the effect of efficient transmission characteristics and regulation of transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

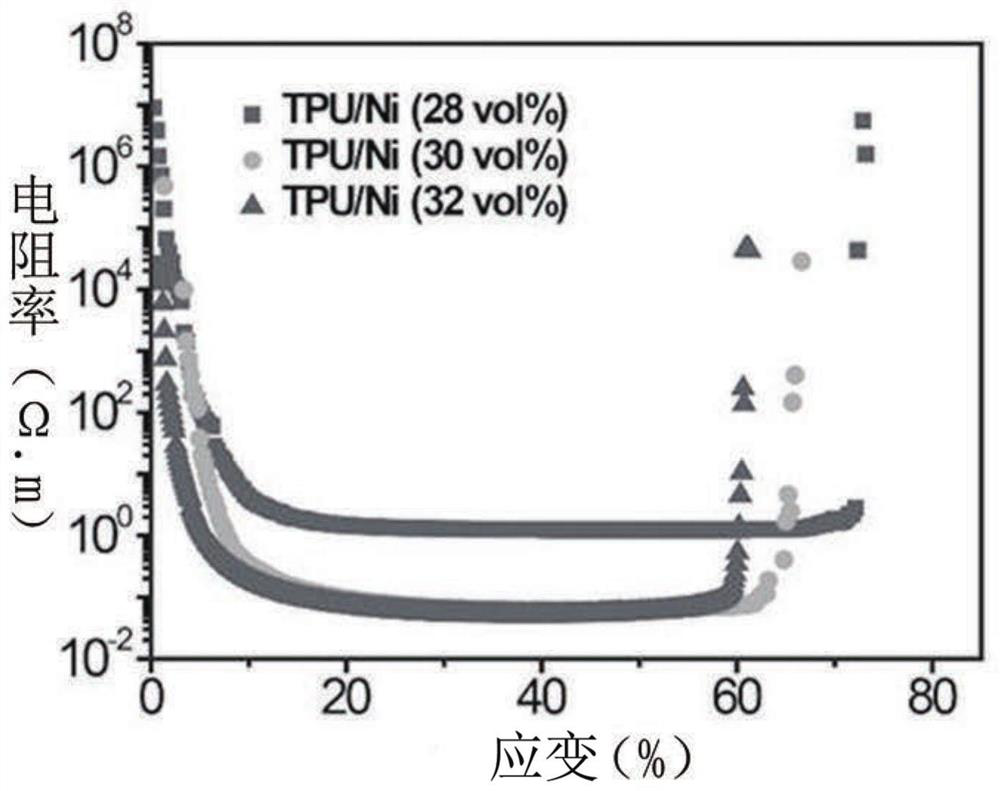

[0025] In an exemplary embodiment of the present invention, the preparation method of a stress-driven flexible terahertz dynamic control material may include the following steps:

[0026] (1) Drying treatment of polymer elastomer base material and conductive particles

[0027] Dry the polymer elastomer base material and conductive particles to remove the moisture in the polymer elastomer base material and conductive particles, so as to avoid partial agglomeration of the base material during the subsequent melt blending of the polymer elastomer base material and conductive particles, resulting in incomplete mixing. uniform. Here, the temperature of the drying treatment may be 60-90° C., and the drying treatment time may be 12-24 hours. For example, the polymer elastomer base material can be one or more of silicone thermoplastic vulcanizate, polyurethane, silicone rubber, styrene block copolymer, ethylene-octene copolymer, and olefin block copolymer. For example, the conductiv...

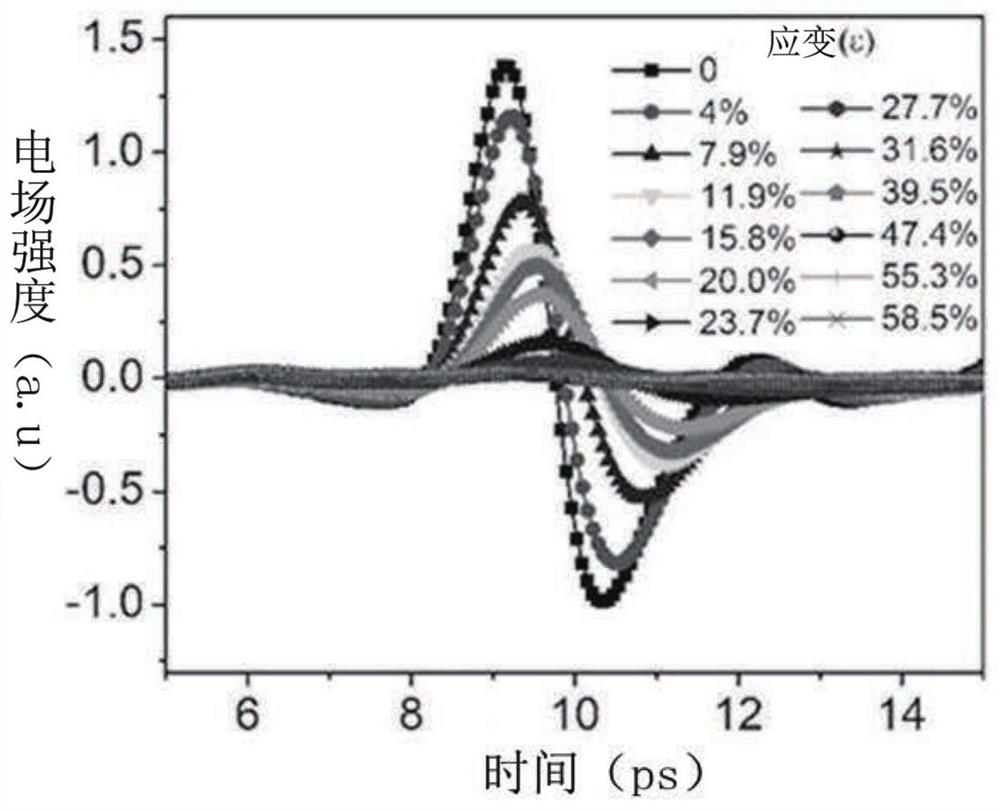

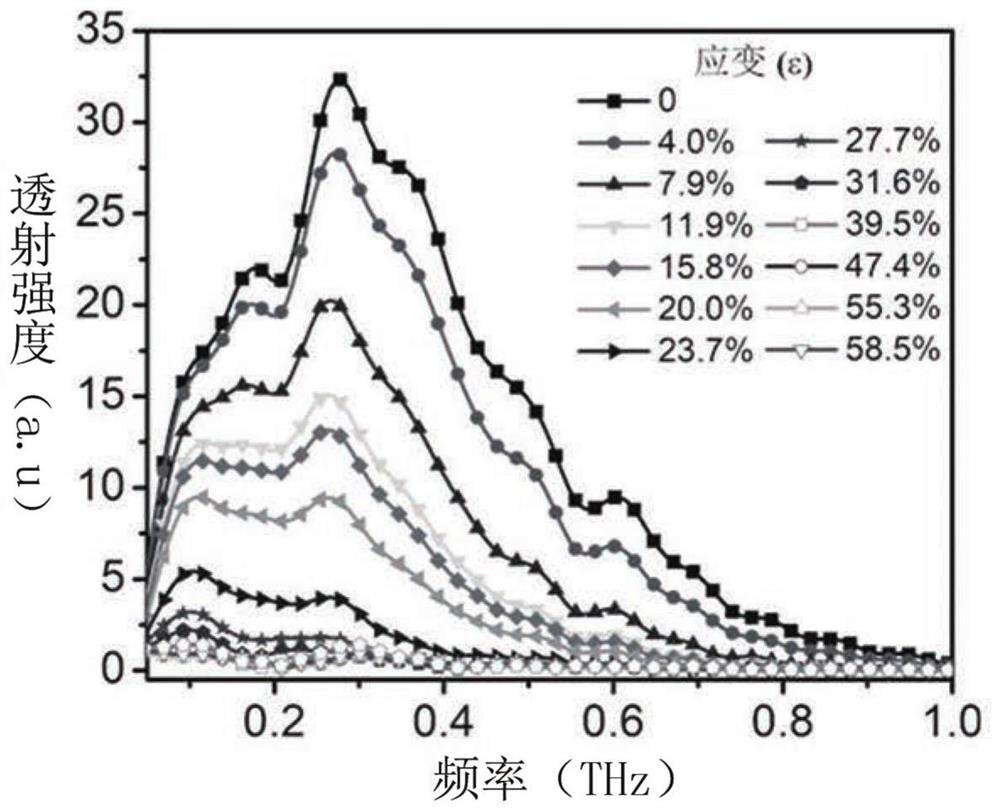

example 1

[0045] The thermoplastic polyurethane and metal nickel particles were dried at 60°C for 24h to remove the moisture in the thermoplastic polyurethane and metal nickel particles. Wherein, the particle diameter of the metallic nickel particles is 50 nm.

[0046] The dried thermoplastic polyurethane and the metal nickel particles are mixed according to the filling ratio of the metal nickel particles at 30 vol% to obtain a mixed powder, and the mixed powder is heated to obtain a melt-blended flexible terahertz dynamic control intermediate. Wherein, the temperature of melt blending is 160° C., and the time of melt blending is 30 min.

[0047] The melt-blended terahertz intermediate is compression-molded to obtain flexible films of flexible terahertz dynamic control materials with different thicknesses. Among them, the temperature of the compression molding process is 150°C, the pressure of the compression molding is 5.5Mpa, and the thickness of the flexible film of the flexible ter...

example 2

[0049] Dry the thermoplastic olefin block copolymer and the metal aluminum particles at 85° C. for 20 h to remove the moisture in the thermoplastic olefin block copolymer and the metal aluminum particles. Wherein, the size of the metal aluminum particles is 5 μm.

[0050]The dried thermoplastic olefin block copolymer and the metal aluminum particles are mixed according to the filling ratio of the metal aluminum particles to 40 vol% to obtain a mixed powder, and the mixed powder is heated to obtain a melt-blended flexible terahertz dynamic control intermediate. Wherein, the temperature of melt blending is 180° C., and the time of melt blending is 20 min.

[0051] The melt-blended terahertz intermediate is compression-molded to obtain flexible films of flexible terahertz dynamic control materials with different thicknesses. Among them, the temperature of the compression molding process is 150° C., the pressure of the compression molding is 10 MPa, and the thickness of the flexi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com