Four-way-bottom construction vertical shaft arranged above underground excavation station and construction method

A technology for the construction of shafts and stations, which is applied to shaft equipment, earthwork drilling, shaft lining, etc., and can solve problems such as difficult control of construction ground subsidence and difficulty in ensuring the stability of shaft structures, achieving small amount of abandoned projects, high implementation efficiency, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

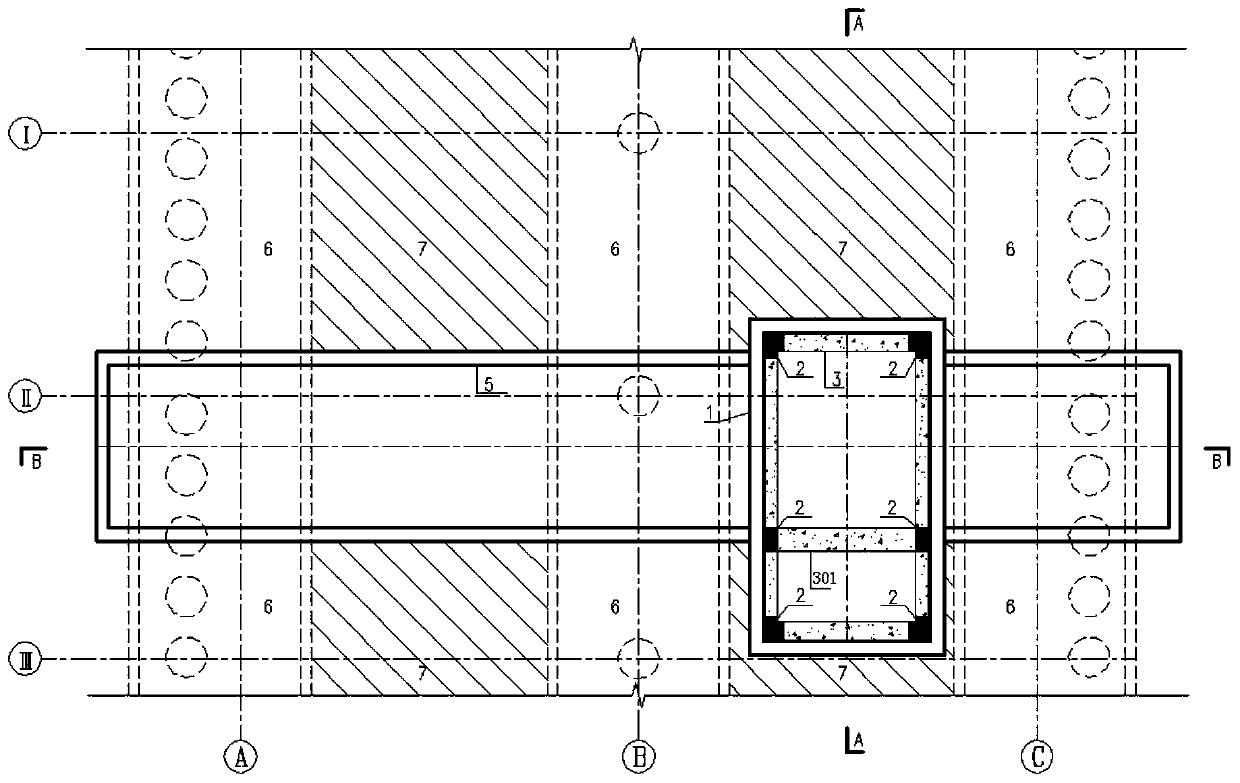

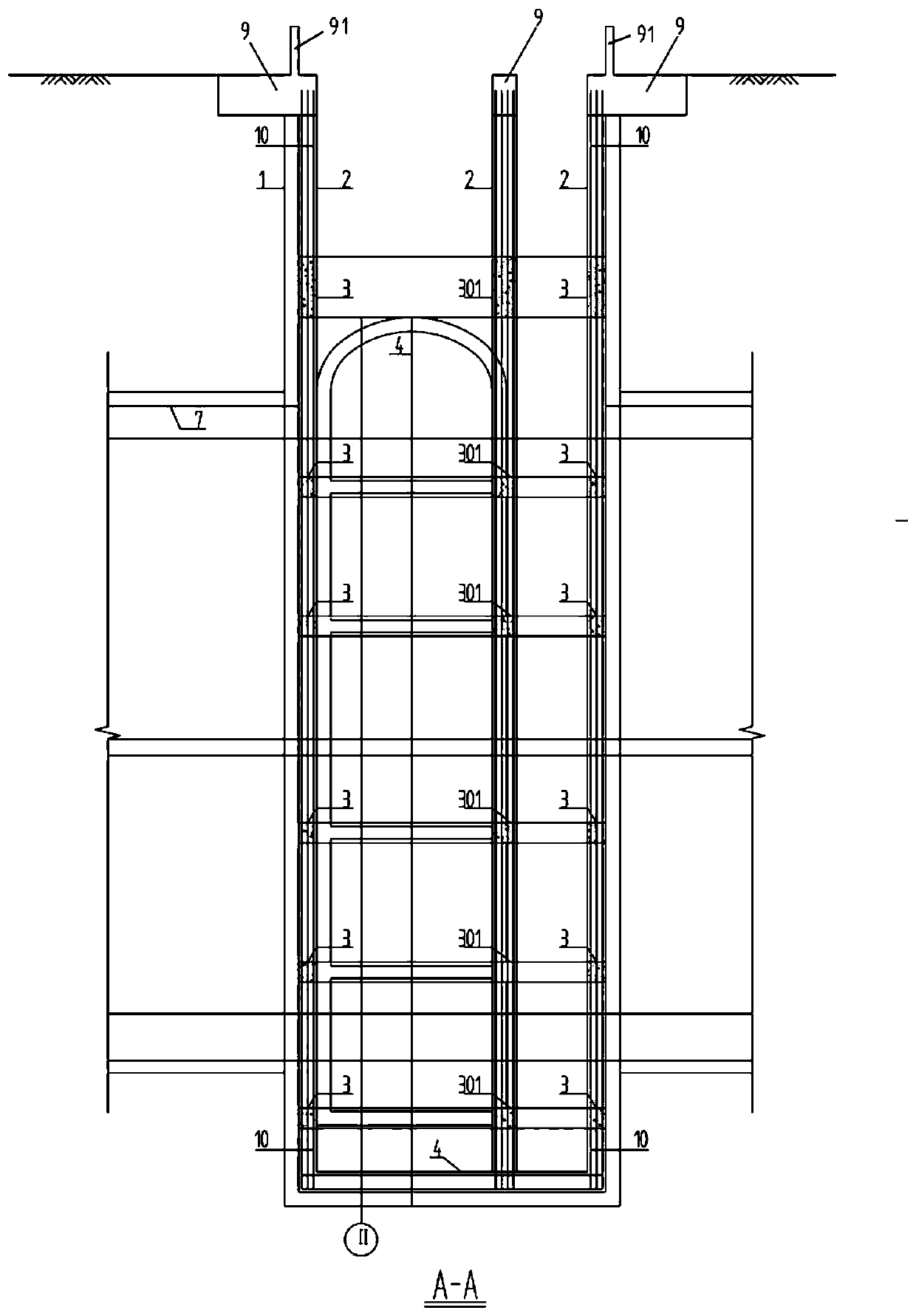

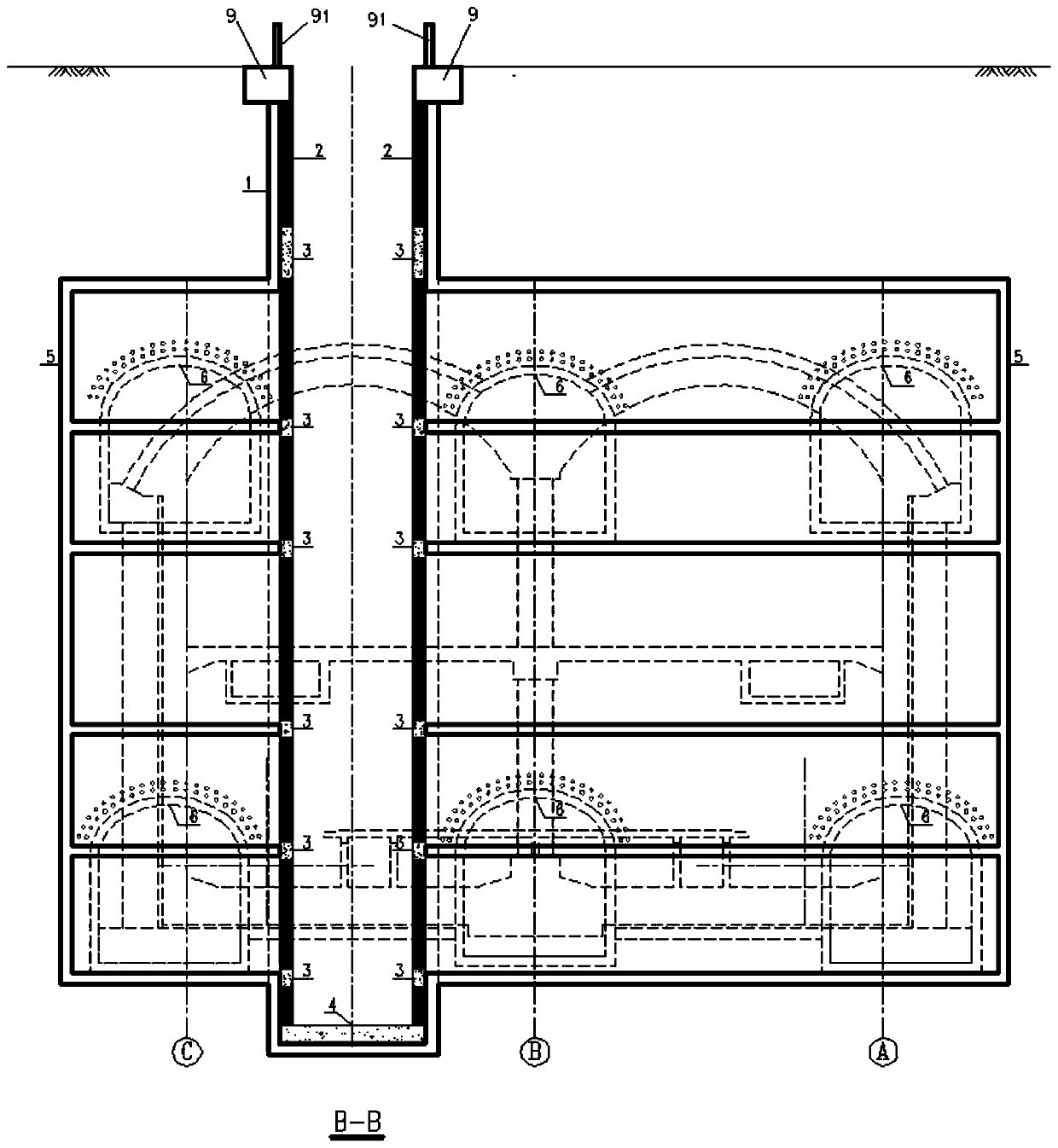

[0036] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0037] Such as Figure 1-4 Shown, a kind of construction method of the construction shaft that is placed at the bottom four-way above the underground excavation station comprises the following construction steps,

[0038] Step 1, construct the lock ring beam 9 at the ground position of the shaft pre-excavation, make the lock ring beam reinforcement cage 92 and reserve the frame column connecting rib 10 at the bottom of the lock ring beam reinforcement cage 92, and pour the lock ring The beam reinforcement cage 92 is made into a lock ring beam 9 and locked into a rectangular wellhead, and a circle of wall reinforcement cage is arranged on the inner ring of the upper end face of the lock ring beam reinforcement cage 92 and is poured into a well head enclosure wall 91 by concrete, see the attached figure 2 , 3 , 7, 10;

[0039] Step 2. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com