Soil sampling device for phyllostachys praecox shoot planting

A technology for soil sampling and bamboo shoots, applied in the field of soil sampling devices for planting thunder bamboo shoots, can solve the problems of lower sampling efficiency, laborious operation, troublesome operation, etc., and achieve the effect of improving sampling efficiency and high sampling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

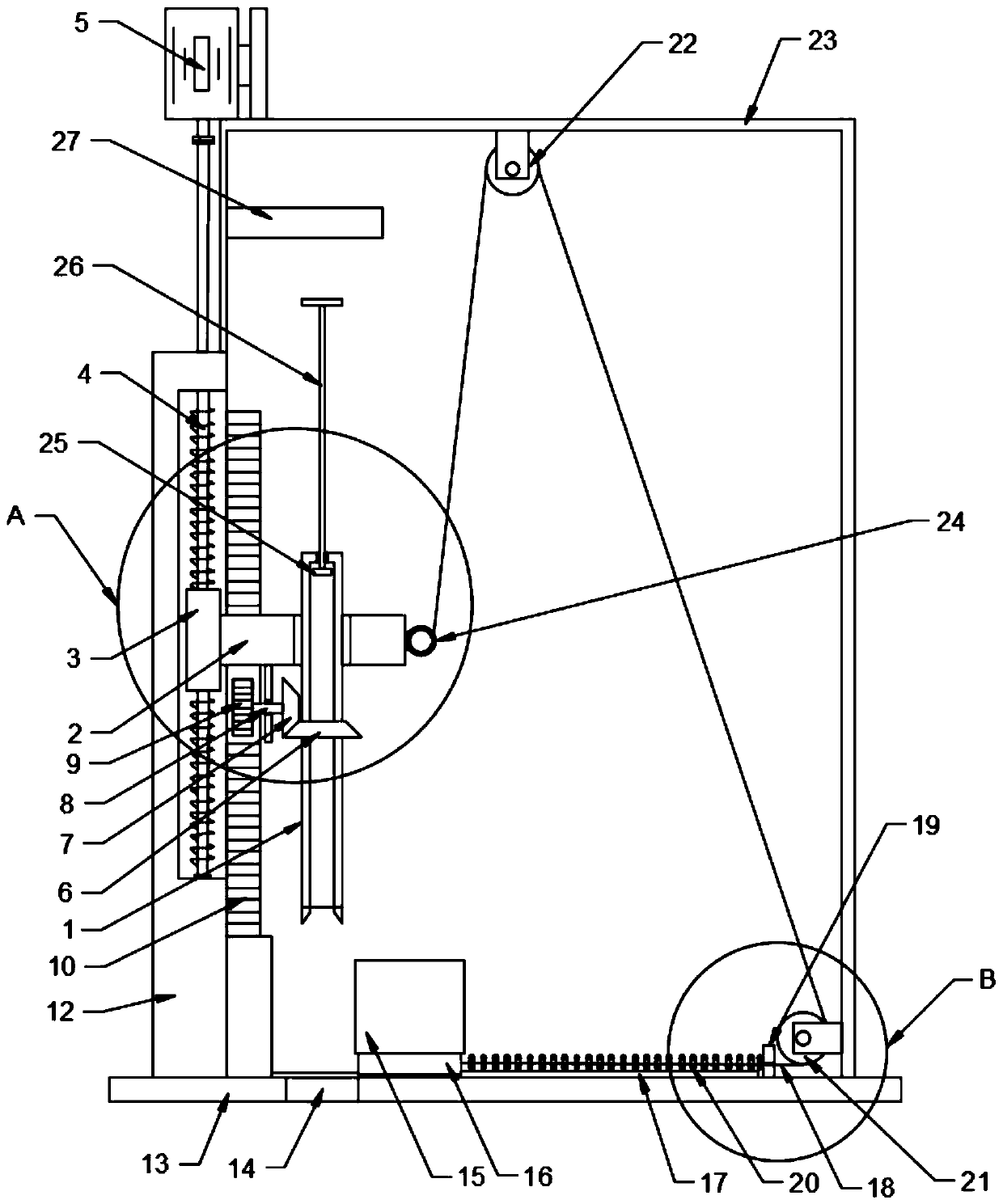

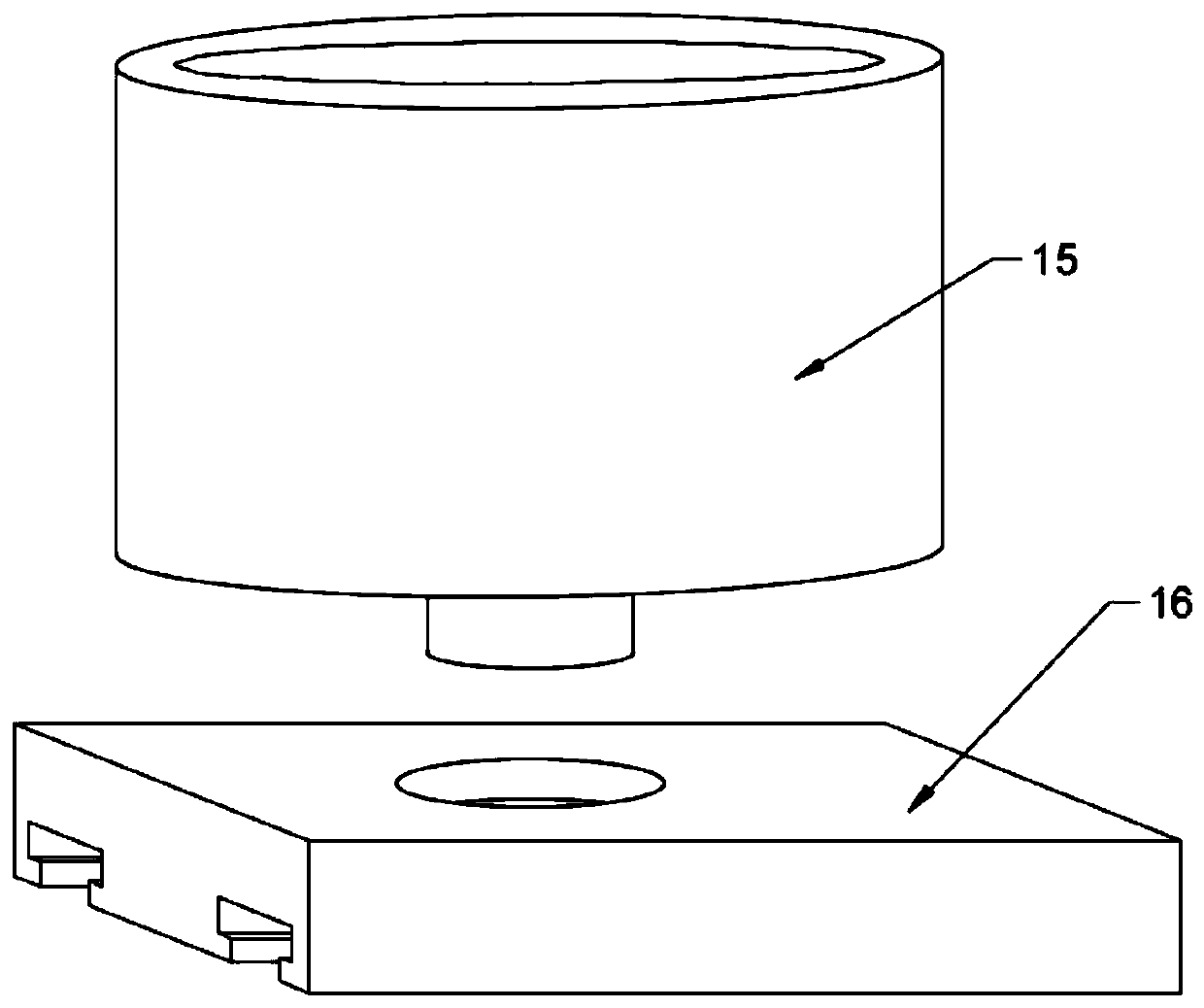

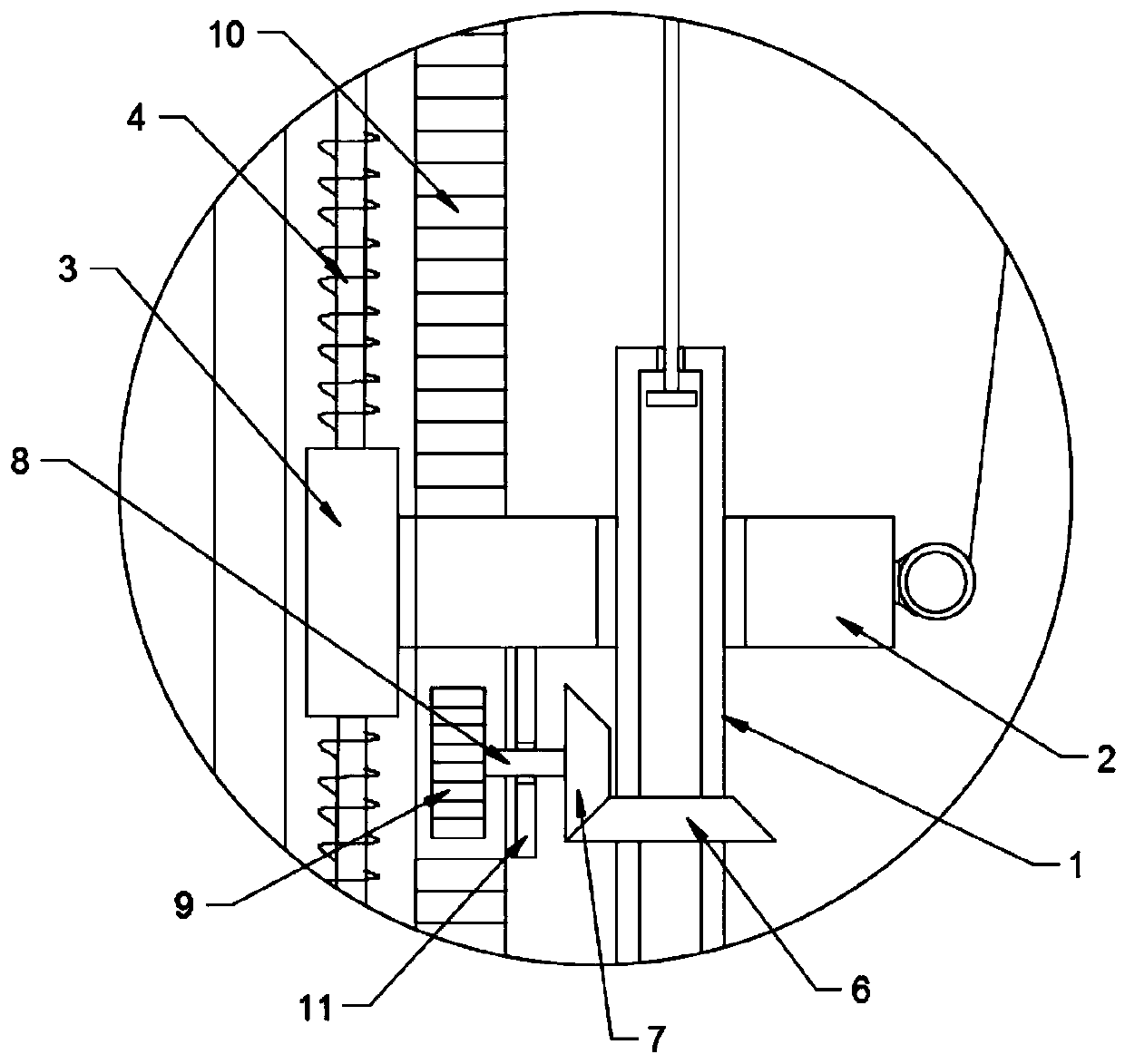

[0021] see Figure 1-4 , in an embodiment of the present invention, a soil sampling device for planting thunder bamboo shoots includes a sampling mechanism and a blanking mechanism; The plate 2 is rotatably connected with the lifting plate 2 through a bearing sleeve; one side of the lifting plate 2 is fixedly connected with a moving block 3, and the moving block 3 is nested with a chute plate 12, and the chute plate 12 is equipped with a vertical chute, the moving block 3 is nested in the vertical chute and is slidably connected with the vertical chute; Extending to the top of the chute frame 12 and connected to the output shaft of the stepping motor 5 through a coupling, specifically, the stepping motor 5 drives the screw mandrel 4 to rotate, and the screw mandrel 4 drives the moving block 3 to move up and down in the vertical chute , the moving block 3 drives the lifting plate 2 and the sampling cylinder 1 on it to move up and down to carry out vertical sampling, the height...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is that in order to reduce manual operations, a steel wire 18 is fixedly connected to the end of the sliding seat 16, the steel wire 18 runs through the limiting plate 19, and a spring 20 is arranged between the limiting plate 19 and the sliding seat 16. , the spring 20 is sleeved on the steel wire 18, and the limiting plate 19 is fixedly connected with the bottom plate 13; The elastic coil 24 is fixedly connected to the end of the lifting plate 2; the first fixed pulley 21 is fixedly connected to the side wall of the protective cover 23, and the second fixed pulley 22 is fixedly connected to the top plate of the protective cover 23; A volute spring is provided inside the elastic reel 24, which is similar to the internal structure of a tape measure. The stiffness coefficient of the vortex spring is smaller than that of the spring 20. Specifically, when the sampling cylinder 1 moves to the top of the blanking cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com