Concrete aggregate precooling device

A concrete aggregate and pre-cooling technology, which is applied to clay preparation devices, household refrigeration devices, mixed operation control devices, etc., can solve the problem of increasing the direct cost of primary air cooling, the large amount of gold deposits used in steel structures, and the complex ice-making process. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

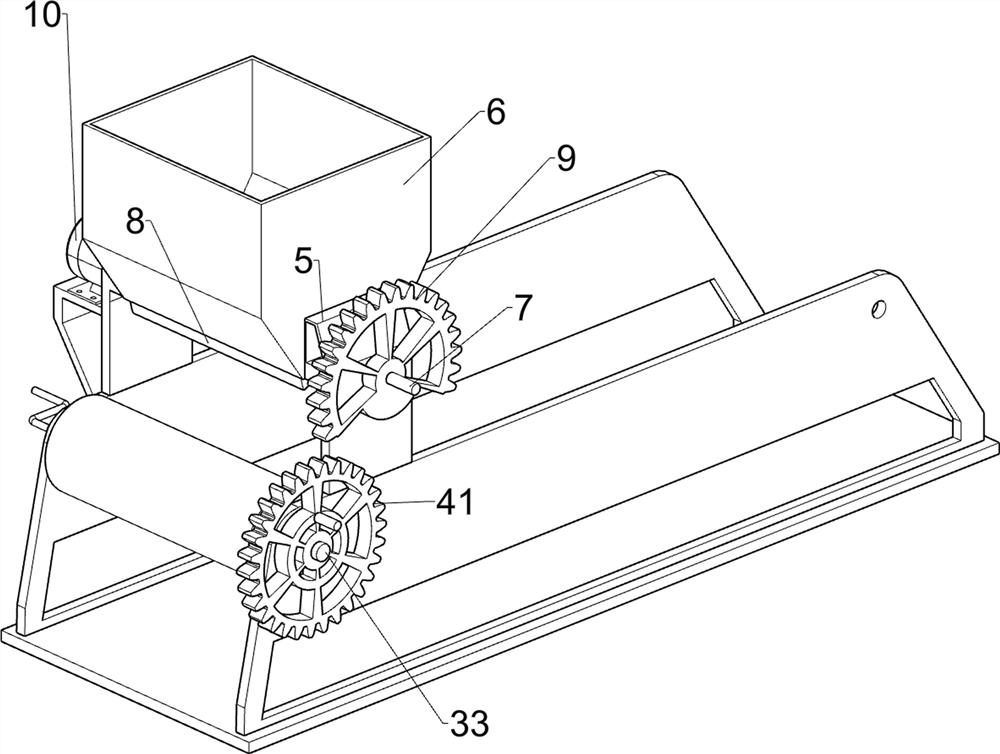

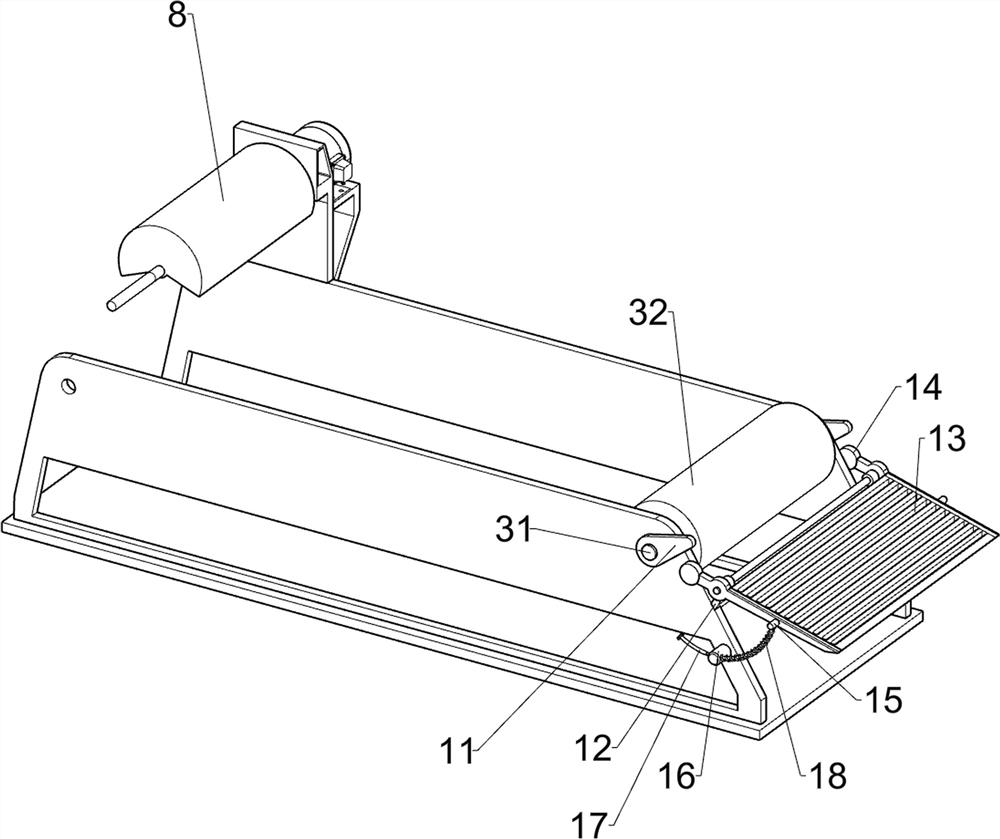

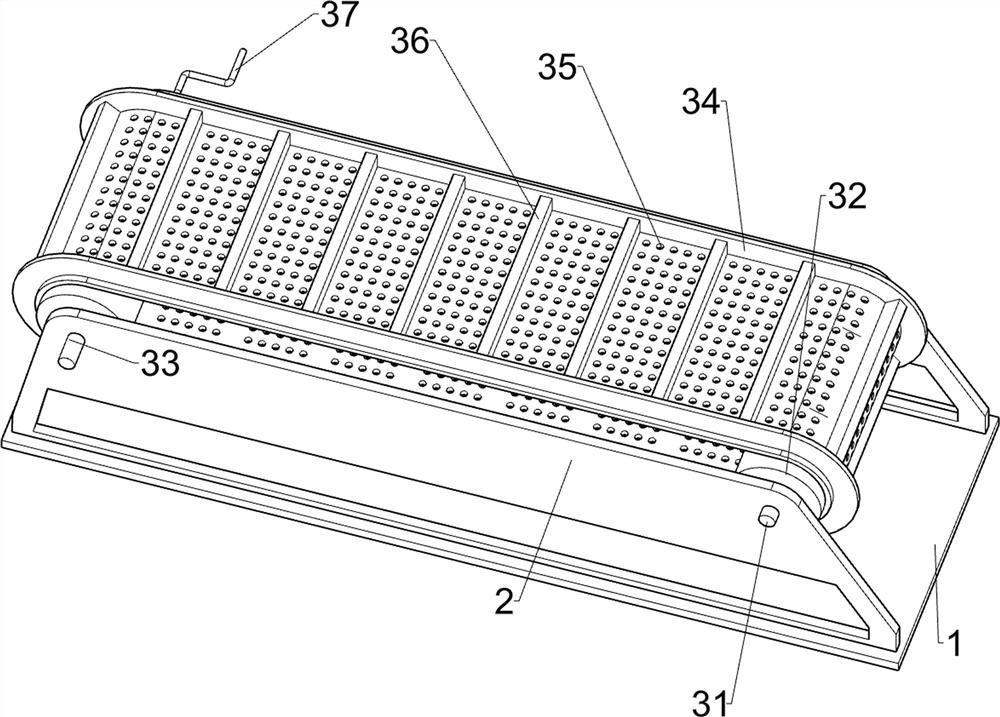

[0022] A concrete aggregate precooling device, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a base 1, a support plate 2, a transmission device 3 and a pre-cooling device 4. The top of the base 1 is fixedly connected with a support plate 2 symmetrically front and rear, a transmission device 3 is provided between the support plates 2, and a transmission device 3 is provided on the support plate 2. Pre-cooling device 4.

[0023] When people need to use this device, first people connect the pre-cooling device 4 to the water pipe, then place the collecting tool on the right side of the conveying device 3, then turn the conveying device 3 to make the conveying device 3 operate, and the conveying device 3 drives the pre-cooling The device 4 works, and then people can pour the aggregate on the left side of the conveying device 3 at intervals, and the conveying device 3 operates to convey the aggregate to the right. When the aggregate move...

Embodiment 2

[0029] On the basis of Example 1, such as Figure 4 and Figure 5As shown, it also includes a second support block 5, a charging box 6, a second rotating shaft 7, a cylindrical missing block 8, a missing gear 9 and a servo motor 10, and the top of the left side of the supporting plate 2 is fixedly connected with a second supporting block 5. A charging box 6 is arranged between the second supporting blocks 5, and the lower part of the charging box 6 is provided with a second rotating shaft 7 in a rotating manner, and the second rotating shaft 7 is rotationally connected with the second supporting blocks 5 on both sides. The second rotating shaft 7 is provided with a cylindrical missing block 8, and the cylindrical missing block 8 is positioned at the inner side of the bottom of the charging box 6. The front end of the second rotating shaft 7 is provided with a missing gear 9, and the missing gear 9 meshes with the circular gear 41. A servo motor 10 is installed between the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com