A concrete aggregate precooling device

A concrete aggregate and pre-cooling technology, which is applied in household refrigeration devices, clay preparation devices, mixing operation control devices, etc., can solve the problem of large excavation for site leveling, complex ice-making building process, and large amount of gold knots for steel structures and other issues to achieve the effect of saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

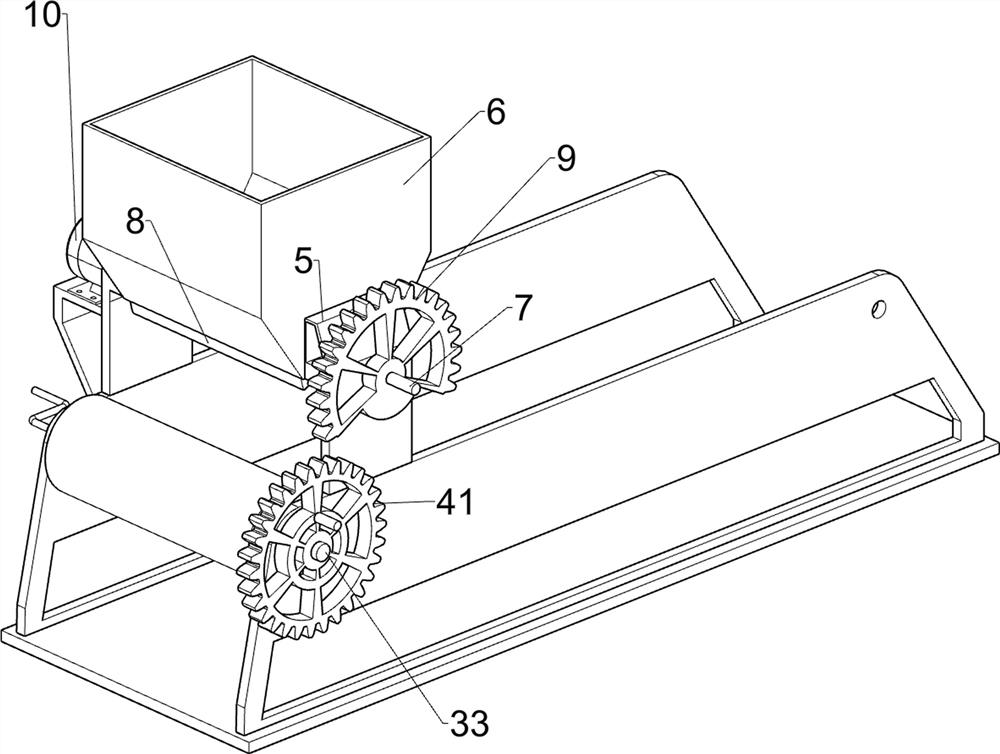

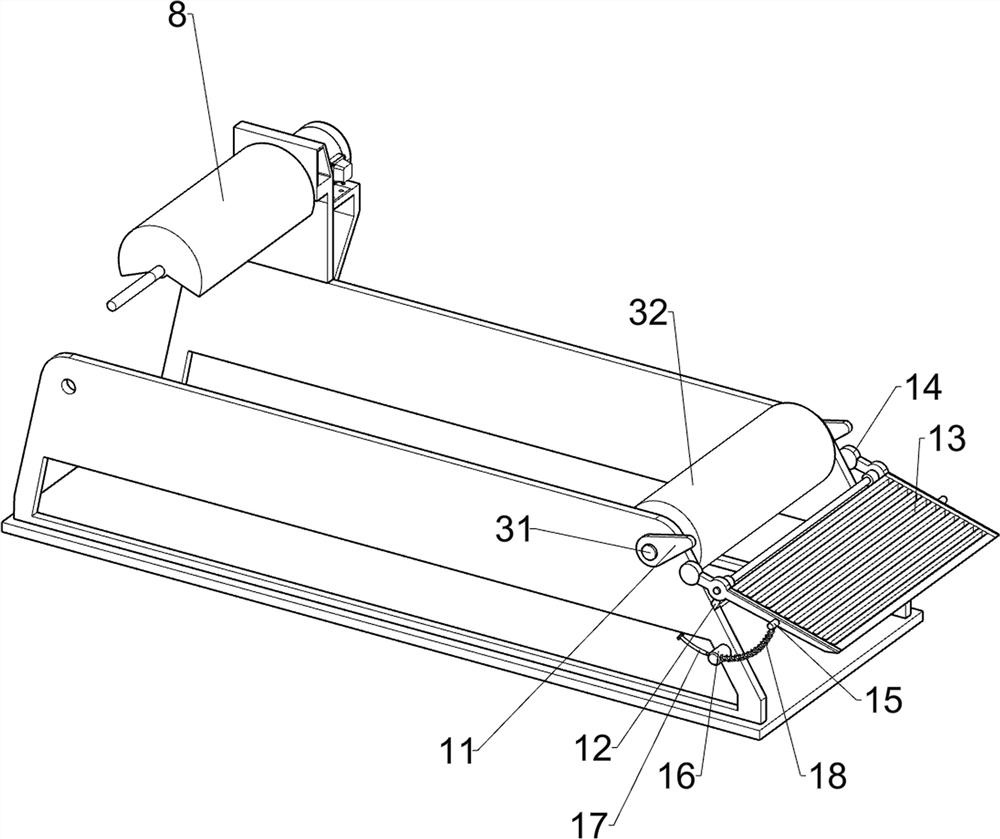

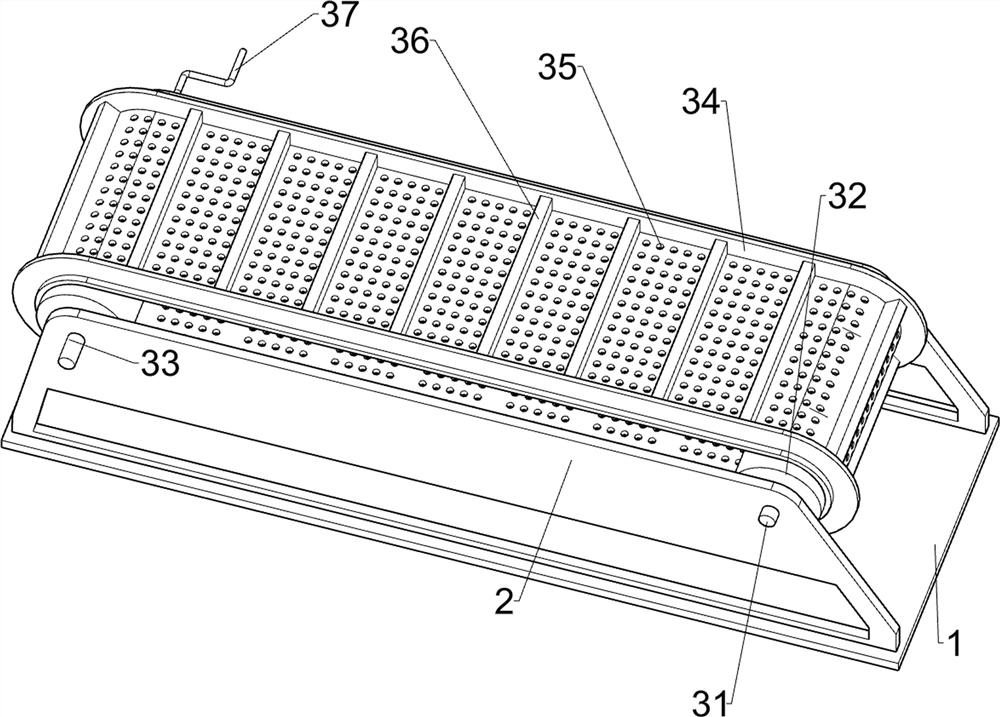

[0022] A concrete aggregate pre-cooling device, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown in the figure, it includes a base 1, a support plate 2, a conveying device 3 and a pre-cooling device 4. The top of the base 1 is fixedly connected with a support plate 2 symmetrically in the front and rear, a conveying device 3 is arranged between the support plates 2, and a support plate 2 is provided with Pre-cooling device 4.

[0023] When people need to use the device, they first connect the pre-cooling device 4 to the water pipe, then place a collection tool on the right side of the conveying device 3, and then rotate the conveying device 3 to make the conveying device 3 operate, and at the same time the conveying device 3 drives the pre-cooling The device 4 operates, and then people can pour the aggregates on the left side of the conveyor device 3. The conveyor device 3 operates to convey the aggregate to the right. When the aggregate moves belo...

Embodiment 2

[0029] On the basis of Example 1, as Figure 4 and Figure 5As shown, it also includes a second support block 5, a charging box 6, a second shaft 7, a cylindrical missing block 8, a missing gear 9 and a servo motor 10, and the top of the left side of the support plate 2 is fixedly connected with a second support block 5. A charging box 6 is arranged between the second support blocks 5. The lower part of the charging box 6 is provided with a second rotating shaft 7 in a rotating manner. The second rotating shaft 7 is rotatably connected with the second supporting blocks 5 on both sides. The second rotating shaft 7 is provided with a cylindrical missing block 8. The cylindrical missing block 8 is located on the inner side of the lower part of the charging box 6. The front end of the second rotating shaft 7 is provided with a missing gear 9. The missing gear 9 meshes with the circular gear 41. A servo motor 10 is installed between the second support blocks 5 , and the output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com