Earth pressure balance shield muck workability and improvement optimization evaluation test system and method

An earth pressure balance shield and evaluation test technology, applied in the direction of using stable tension/pressure test material strength, strength characteristics, suspension and porous material analysis, etc., can solve the problem of difficult to form plastic samples, muck work Loss of objectivity, increased testing workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

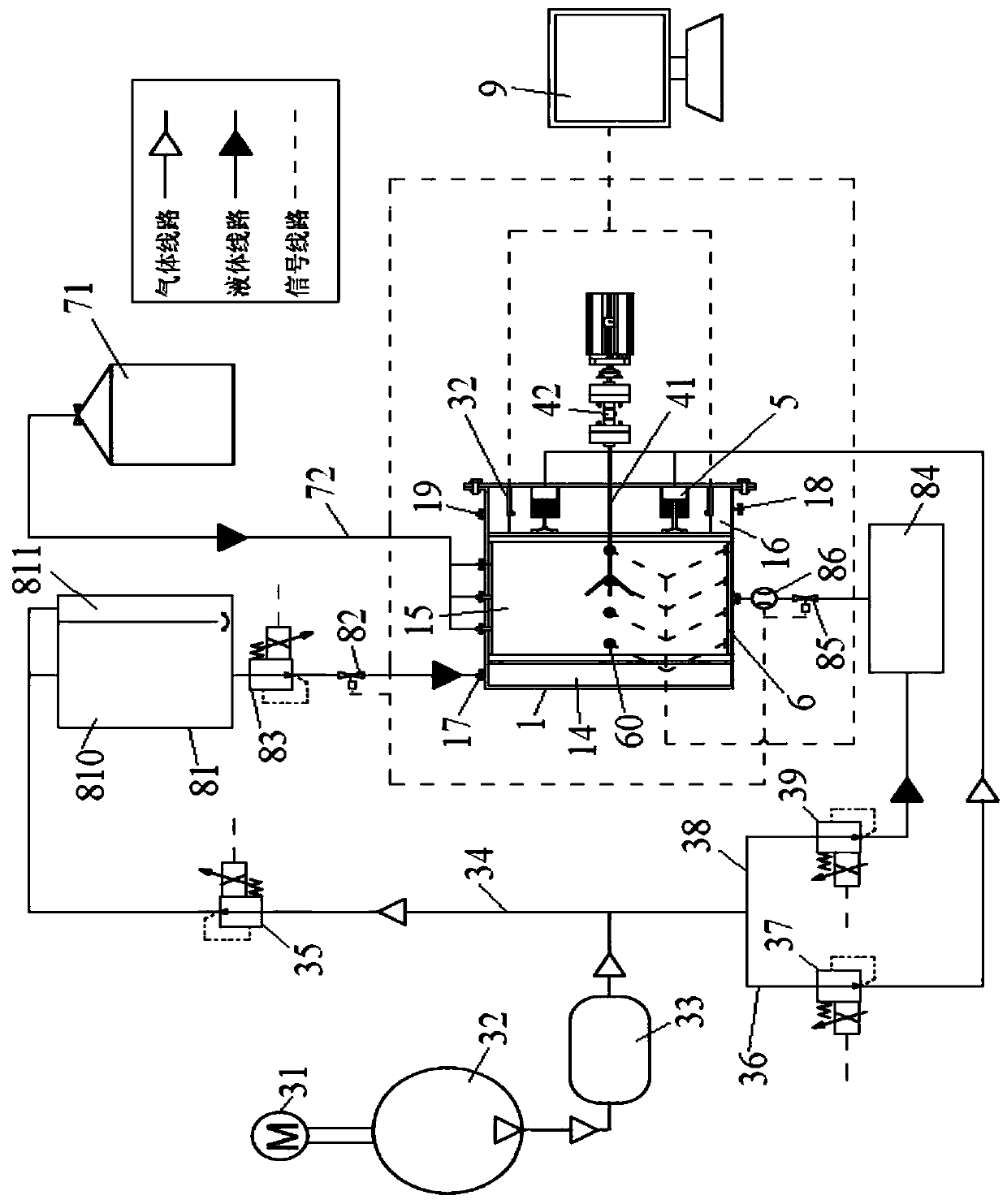

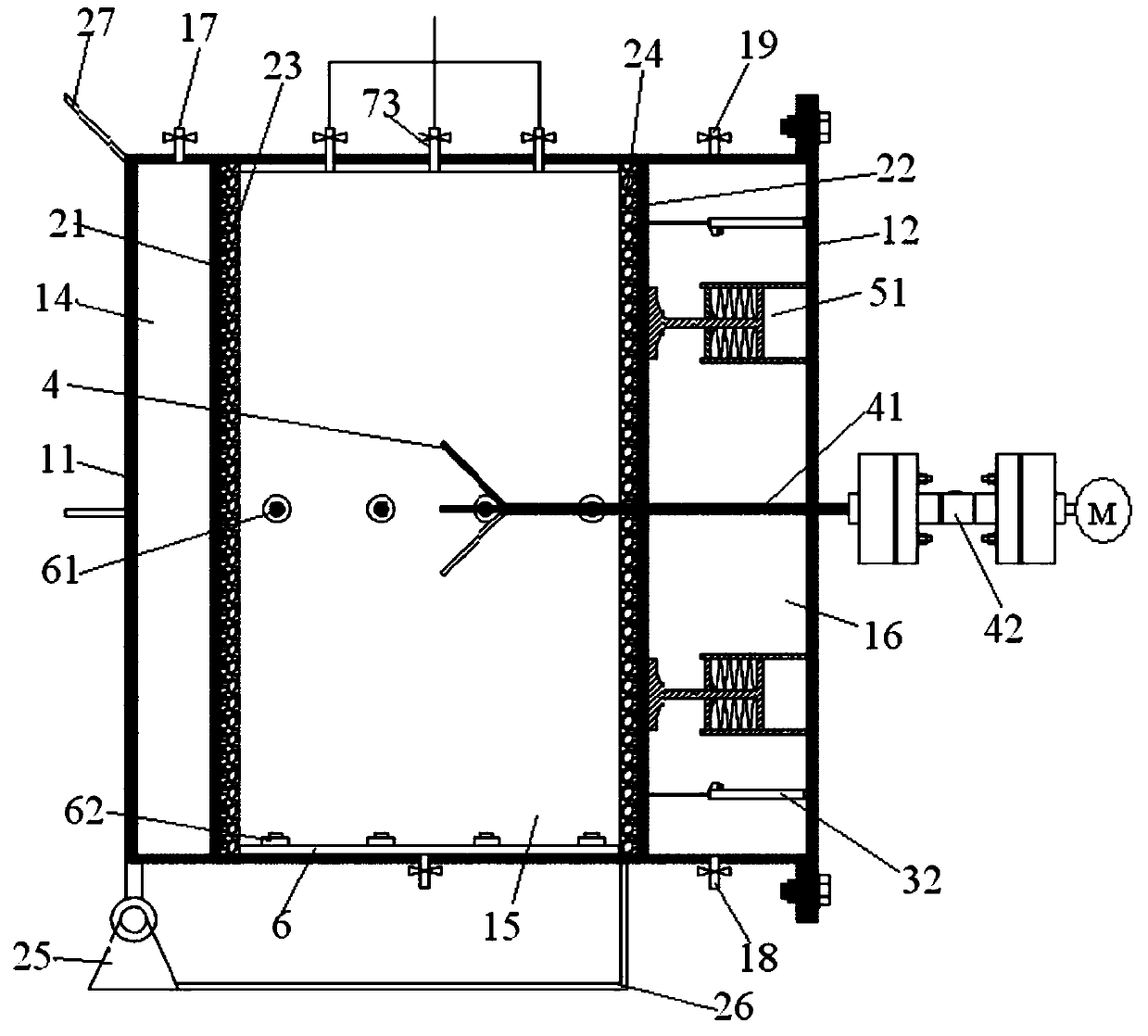

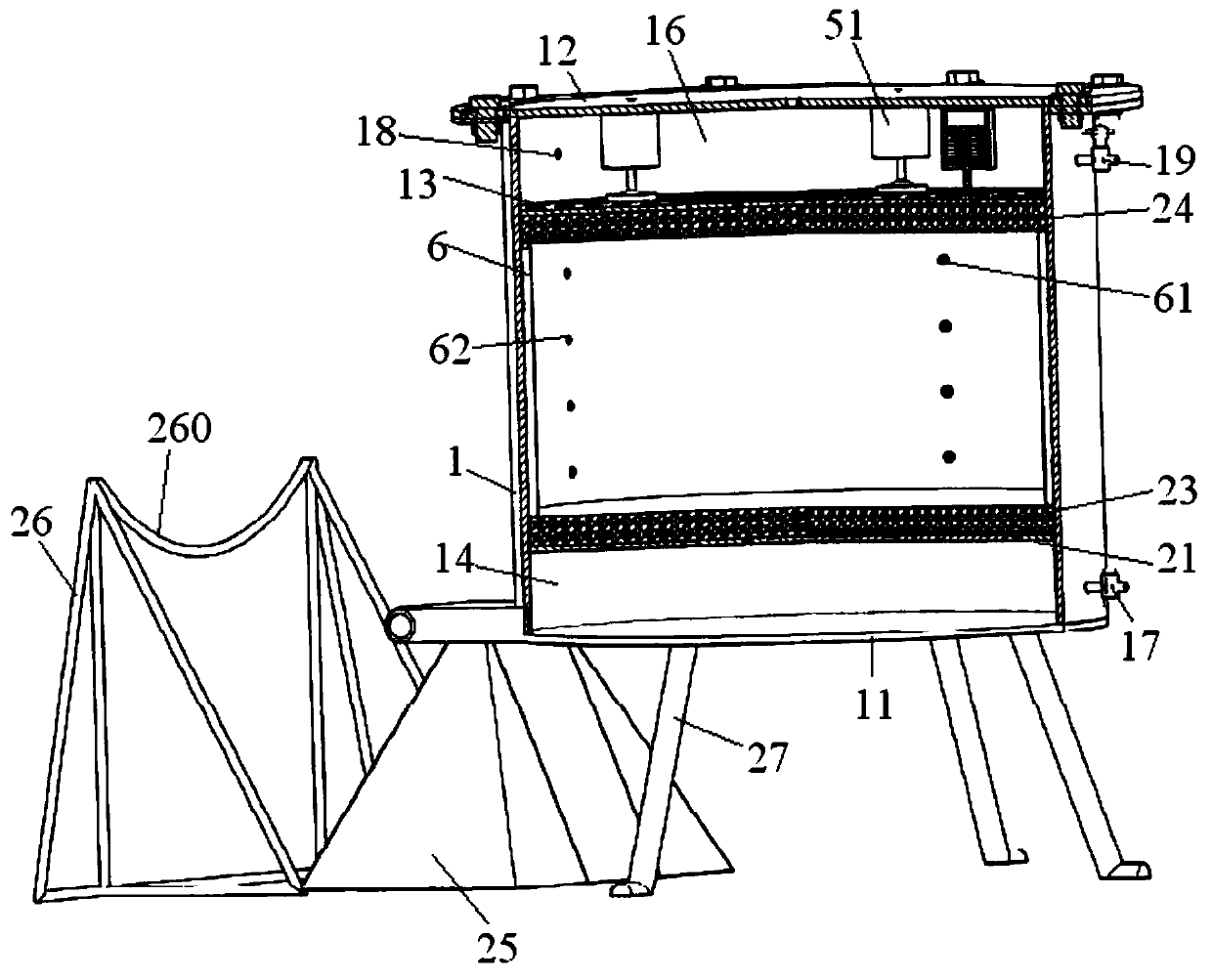

[0062] see Figure 1 ~ Figure 4 see Figure 1 ~ Figure 4 An earth pressure balance shield muck workability and improvement optimization evaluation test system, including a water supply system, a test cylinder 1, a fixed plate 21, a movable plate 22, a water-permeable pad 23, a water-permeable pad 2 24, a shear bar 4, Shear transmission rod 41, axial loading device 5, axial displacement sensor 32, radial extrusion ring bag 6 and test chamber pressure sensor 60;

[0063]The axial direction of the test cylinder is set along the horizontal direction, the left end of the test cylinder is closed by its sealing plate 11, the right end of the test cylinder is provided with an opening, and the right end opening is closed by its end cover 12, and the end cover can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com