Novel three-phase power frequency IGBT pulse width modulation high-voltage power supply for electric precipitation

A high-voltage power supply and pulse width modulation technology, applied in the field of electrostatic precipitator, can solve the problems of large electric corrosion, disadvantage and high energy consumption, and achieve the effect of saving power consumption, avoiding the influence of electric corrosion, and reducing the transient impulse current of flashover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

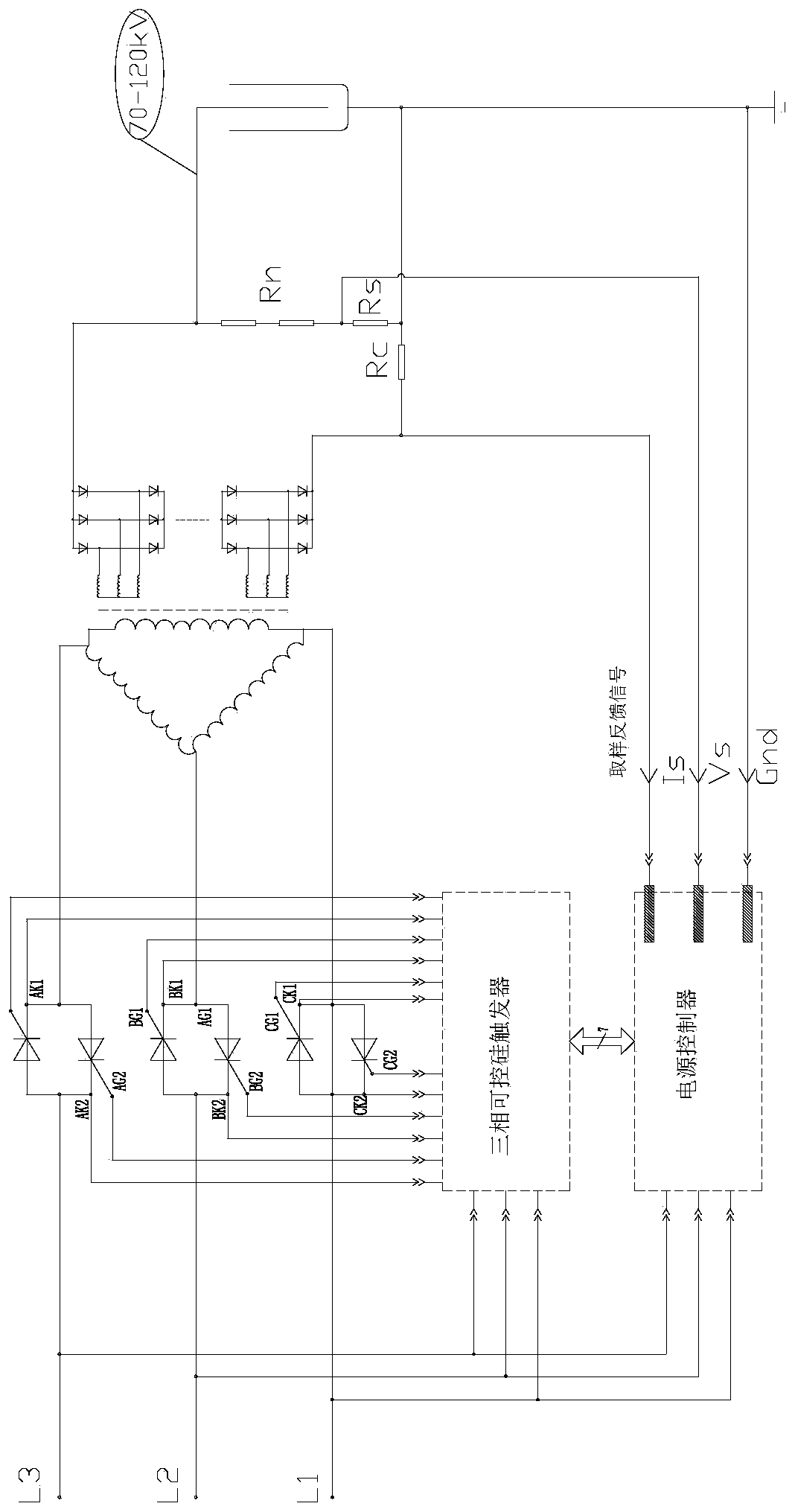

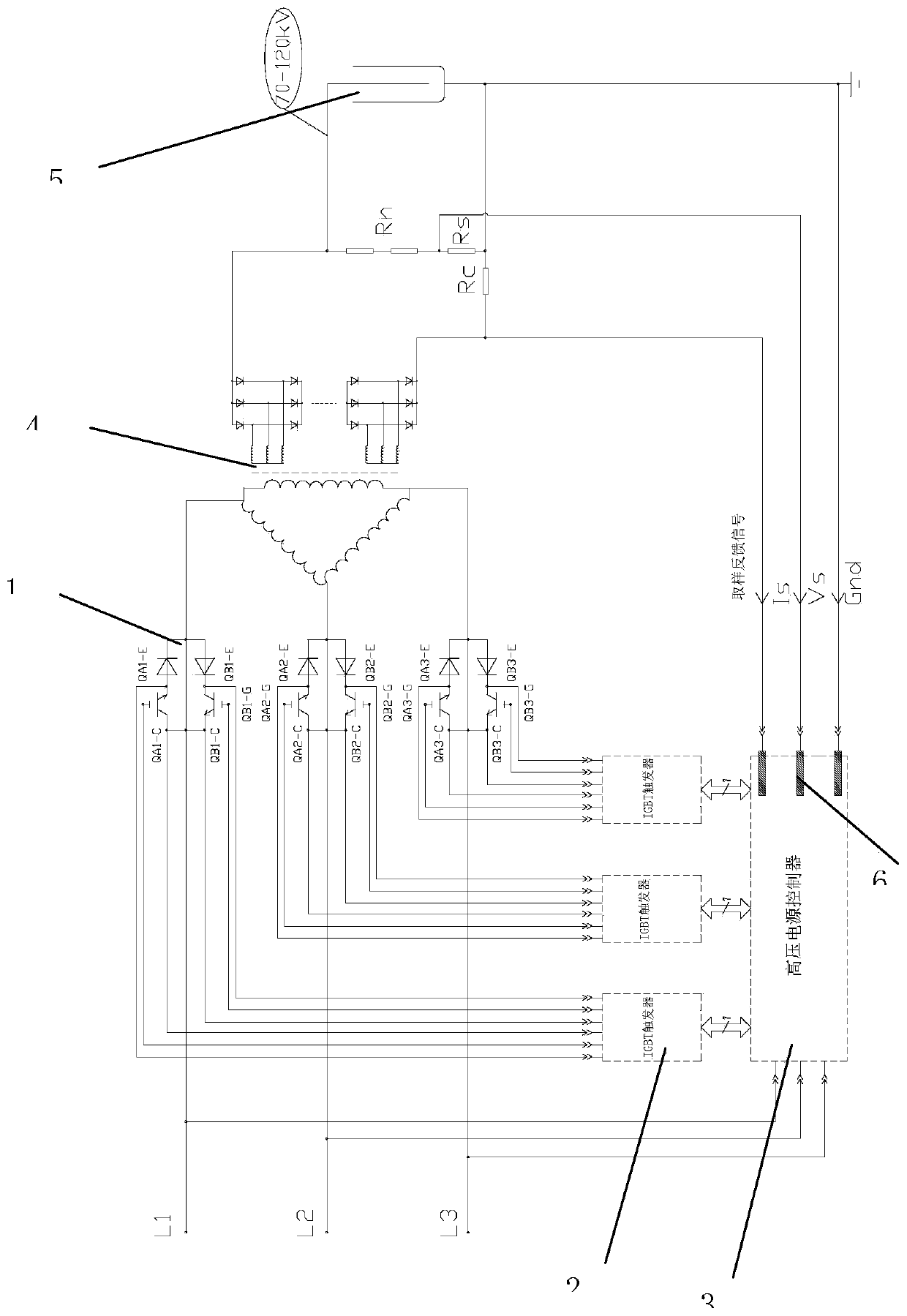

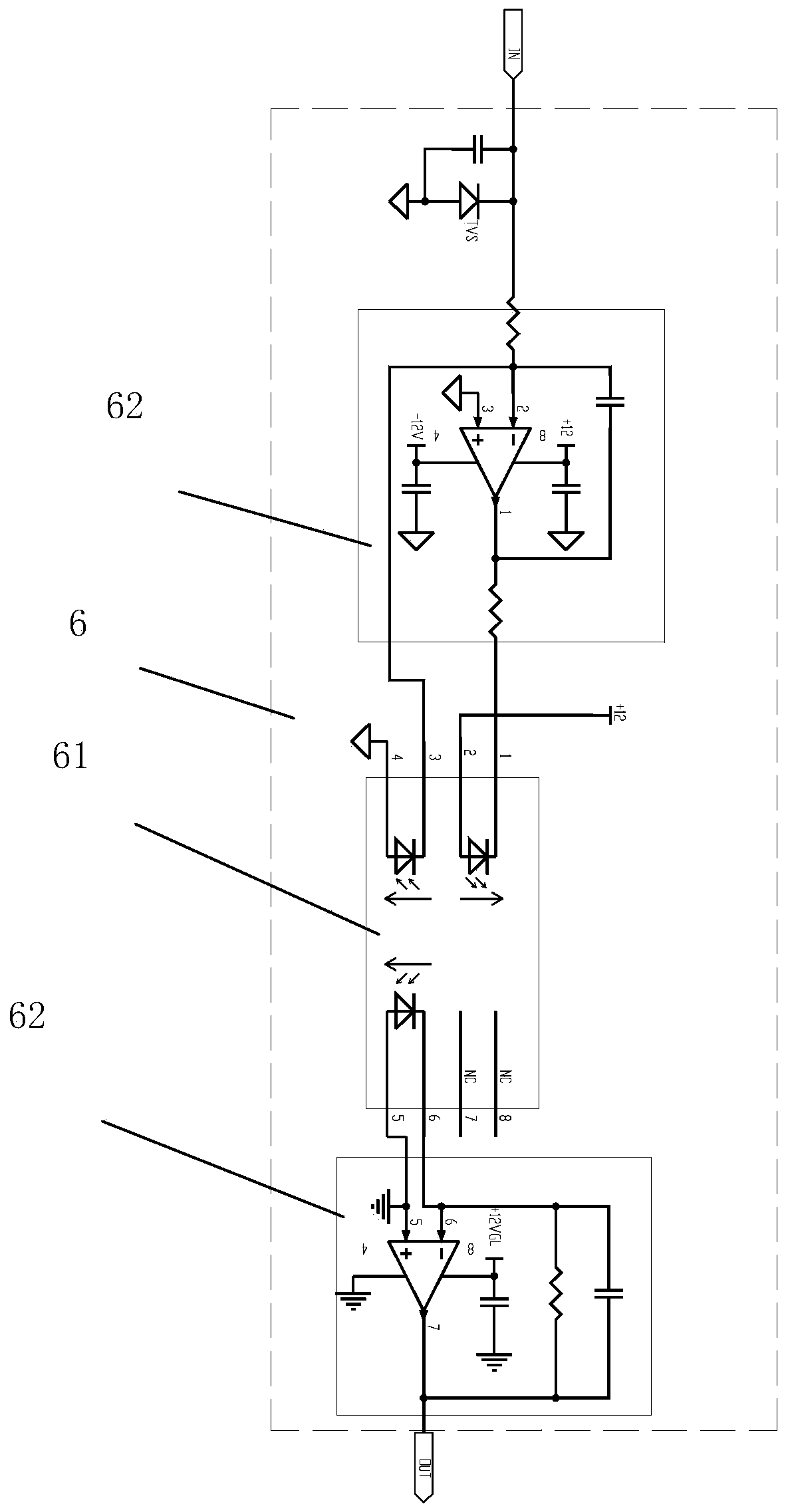

[0024] Such as figure 2 As shown, a new type of three-phase power frequency IGBT pulse width modulated high voltage power supply for electrostatic precipitator can include a main circuit, a three-way IGBT trigger 2, a high voltage power supply controller 3 and a current and voltage sampling circuit. The main circuit is composed of three three-phase IGBT anti-parallel circuits 1, and each three-phase IGBT anti-parallel circuit 1 is composed of two IGBTs and two diodes which are divided into two circuits which are respectively connected in series and then connected in anti-parallel. That is, the gate of one IGBT (QA1, QA2 or QA3) is connected in series with a diode, the gate of the other IGBT (QB1, QB2 or QB3) is connected in series with another diode, and then connected in reverse parallel. In the three-phase IGBT anti-parallel circuit 1, the forwar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap