Base station and cleaning robot system

A cleaning robot and base station technology, applied in the field of cleaning robots, can solve problems such as poor immediacy and energy waste, and achieve the effect of reducing loss and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

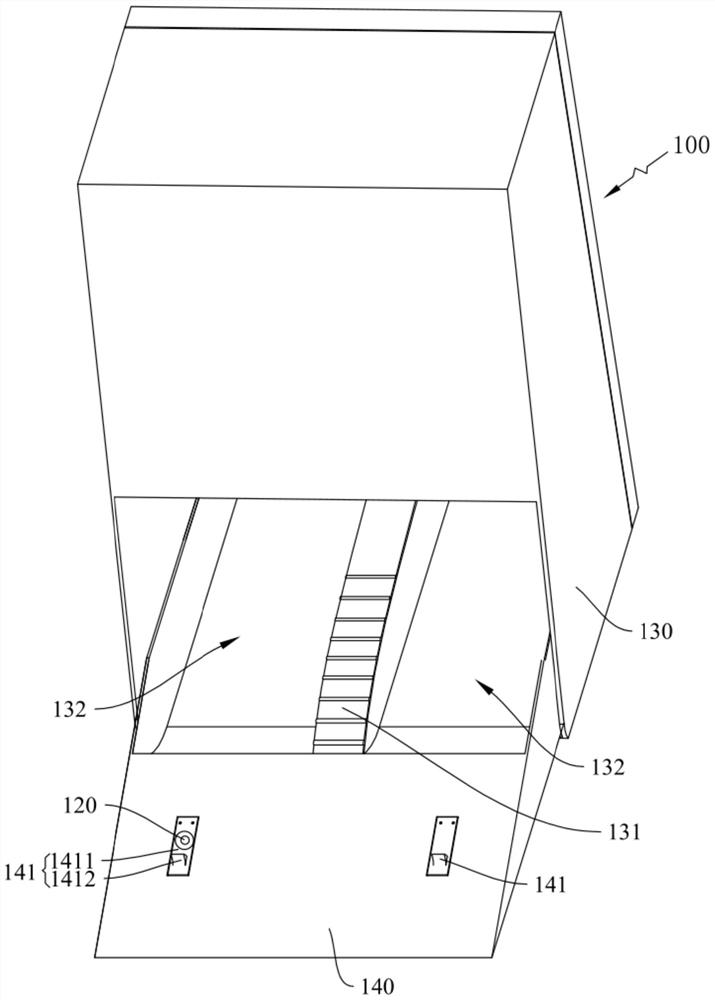

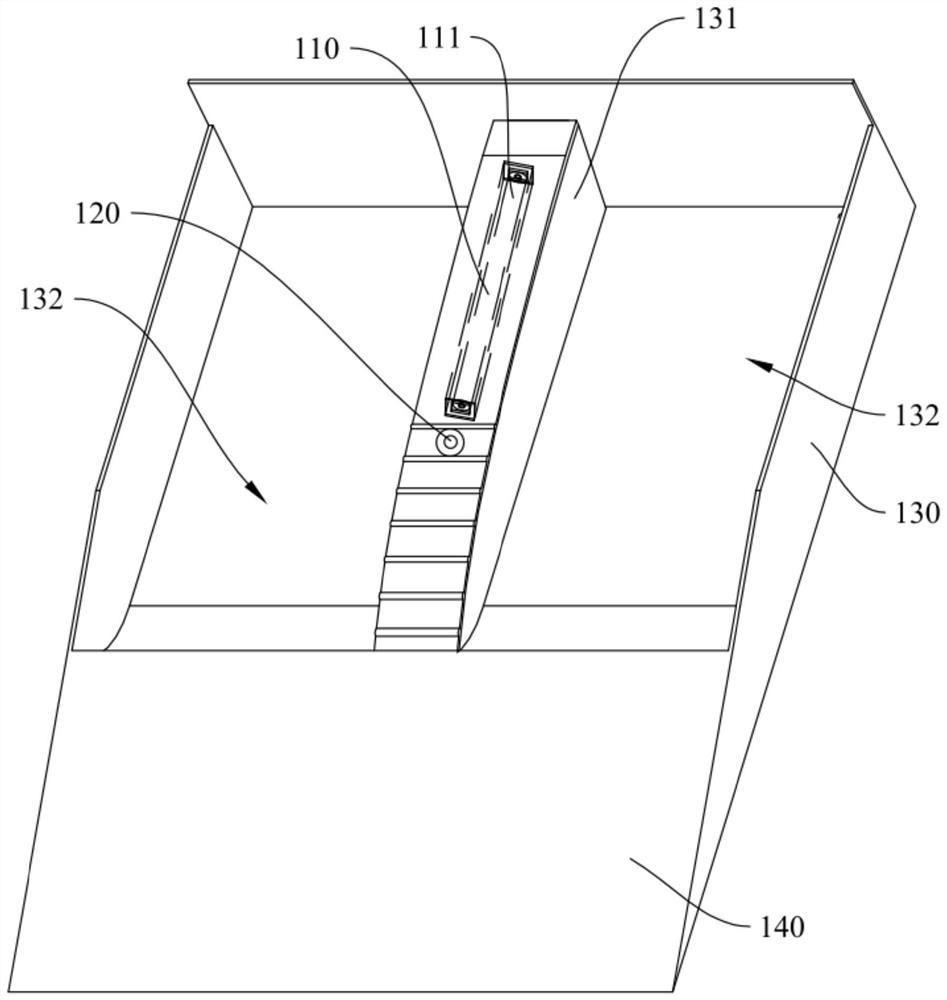

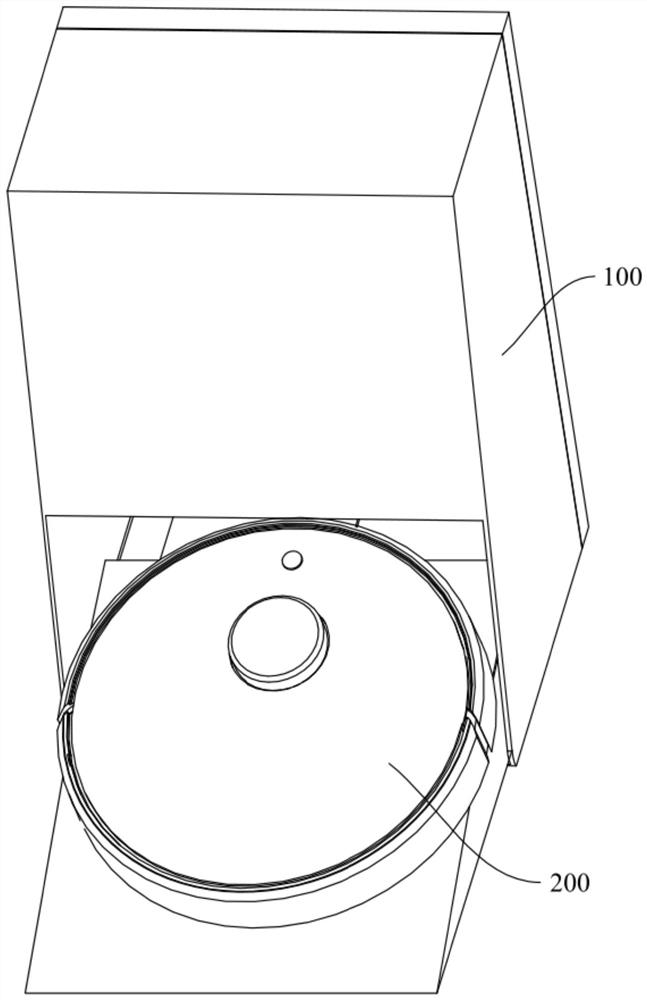

[0032] see figure 1 , figure 2 , image 3 , the embodiment of the present invention provides a base station 100, including at least one functional component 110 and at least one trigger structure 120, the trigger structure 120 is electrically connected to the at least one functional component 110, when the cleaning robot 200 enters the base station 100, the trigger structure 120 is activated trigger and make the functional component 110 electrically connected to it work.

[0033] It should be noted here that when the cleaning robot 200 moves into the base station 100, the trigger structure 120 will be triggered relatively immediately (with a slight delay), and then, one or more devices electrically connected to the triggered trigger structure 120 The functional components 110 can work immediately and play corresponding functions.

[0034] Conversely, when the cleaning robot 200 moves away from the base station 100, the trigger structure 120 is released relatively immediate...

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 is:

[0063] see Figure 5 , in this embodiment, the base station 100 includes a base 130 and a guide plate 140, the guide plate 140 is used to guide the cleaning robot 200 into the base 130, and the guide plate 140 is provided with a plurality of stops for limiting the parking of the traveling wheels 220 The structure 141 ; the triggering structure 120 is disposed on a side of the docking structure 141 away from the base 130 .

[0064] It should be noted here that the base 130 is provided with functional components 110 such as a cleaning mechanism, at least capable of cleaning the cleaning cloth 210 of the cleaning robot 200 . The surface of the guide plate 140 is inclined between the base 130 and the ground, so as to guide at least part of the cleaning robot 200 into the base 130 . Wherein, corresponding to each walking wheel 220 of the cleaning robot 200, the guide plate 140 is provided with a plurality of par...

Embodiment 3

[0068] The difference between this embodiment and Embodiment 1 is:

[0069] Please refer to figure 1 , in this embodiment, the docking structure 141 is in the shape of a groove.

[0070] By adopting the above scheme, the groove-shaped docking structure 141 can make the traveling wheel 220 stably stagnate and stop at the position when the traveling wheel 220 is partially sunk in it and has no driving force, so that the base station 100 is convenient for cleaning the robot 200. corresponding assignment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap