Eddy permeation ejection burner

A burner and vortex technology, applied in burners, gas fuel burners, combustion methods, etc., can solve problems such as uneven distribution, insufficient combustion, and insufficient firepower, and achieve ecological environment protection, obvious combustion-supporting effect, and combustion. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

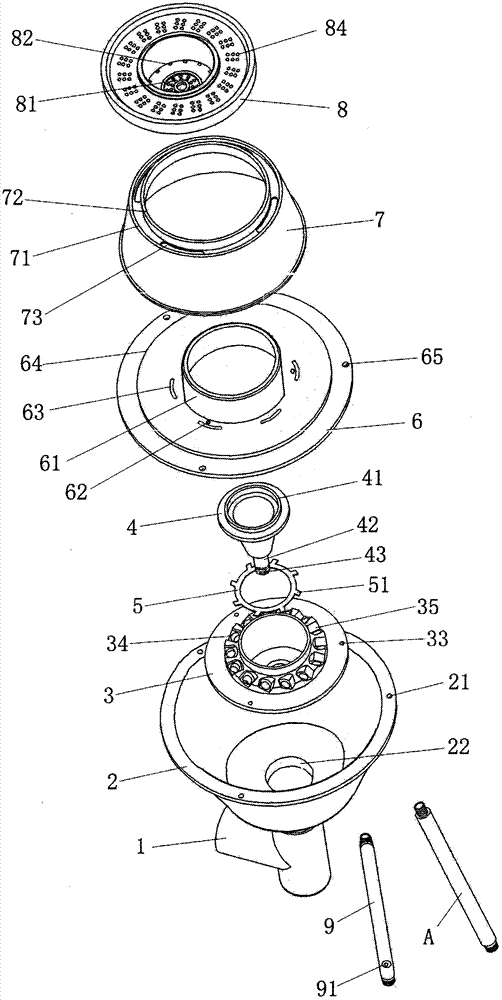

[0034] exist figure 1 , 2 , 3, 4, 5, and 6:

[0035] The upper end of the three-way pipe 1 is provided with an internal thread 11, and the center of the lower end is provided with a through hole 12.

[0036] Three equal screw holes 21 are arranged on the periphery of the upper mouth of the windshield 2, and a pipe body 22 is arranged outside the center of the lower bottom. A through hole 24 is provided outside the body 22 .

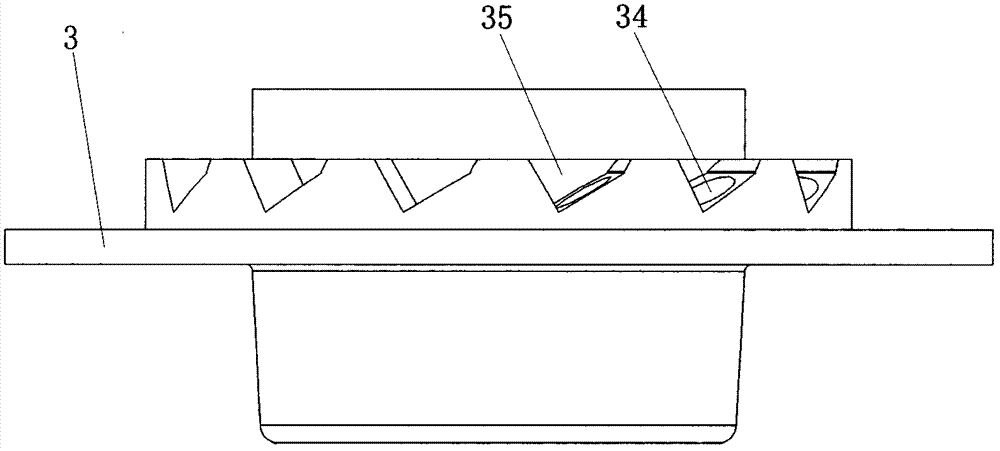

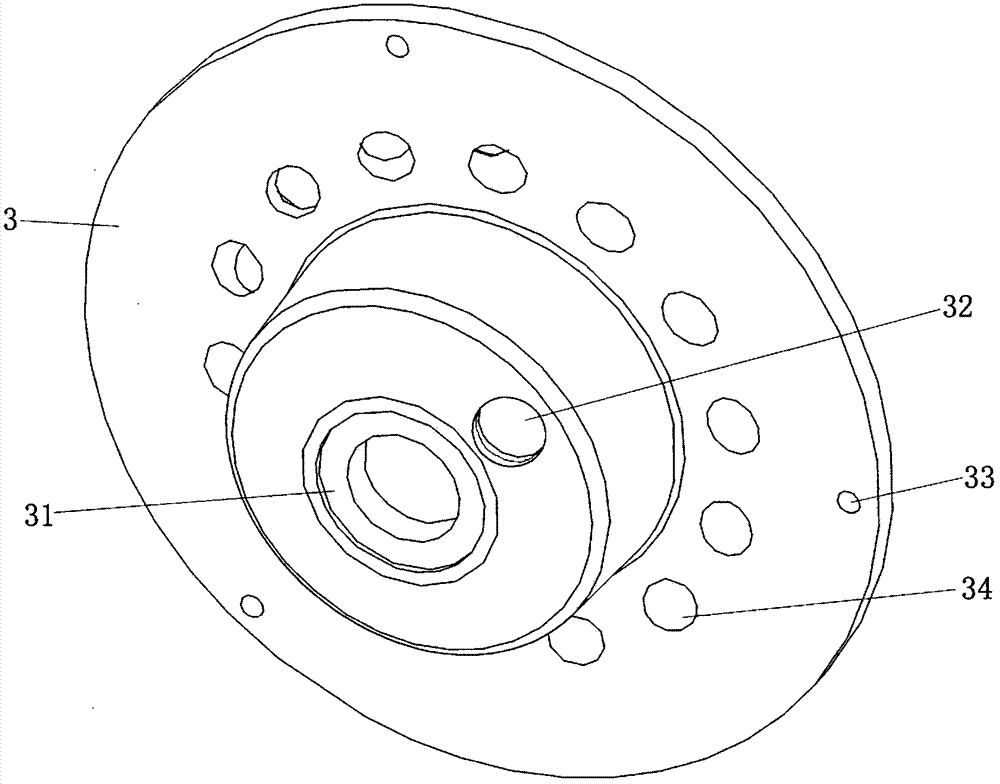

[0037] The center of the lower bottom of the vortex seat 3 is provided with a through hole 31, and the outside of the through hole 31 is provided with a screw hole 32. The outer periphery of the body is provided with an upper and lower two-stage ring body, and the periphery of the lower ring body is provided with three equal through holes 33. The ring body is provided with a plurality of equal through-holes 34 with the same aperture, the same direction, and the same inclination angle (the interval is [25°, 35°], 30°), and the upper end of each through-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com