Six-face visual inspection and material discharging sorting mechanism

A technology of visual inspection and inspection mechanism, which is applied in sorting and other directions, can solve the problems of less involvement in the appearance inspection of tiny components, the inability to use hardware for subdivision of tiny components, and the low efficiency of subdivision of tiny components, achieving model conversion time Short, improved work efficiency and output, low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

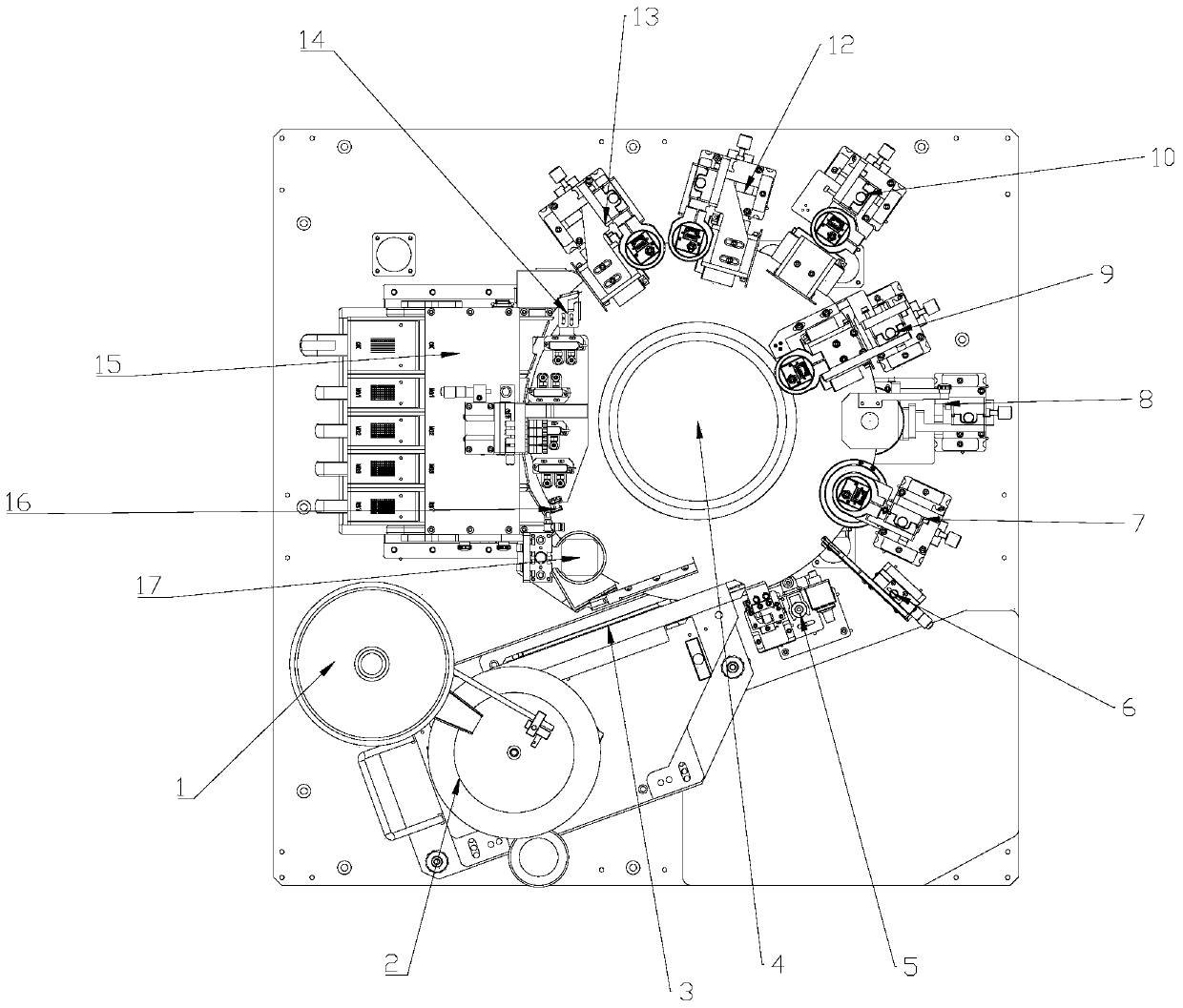

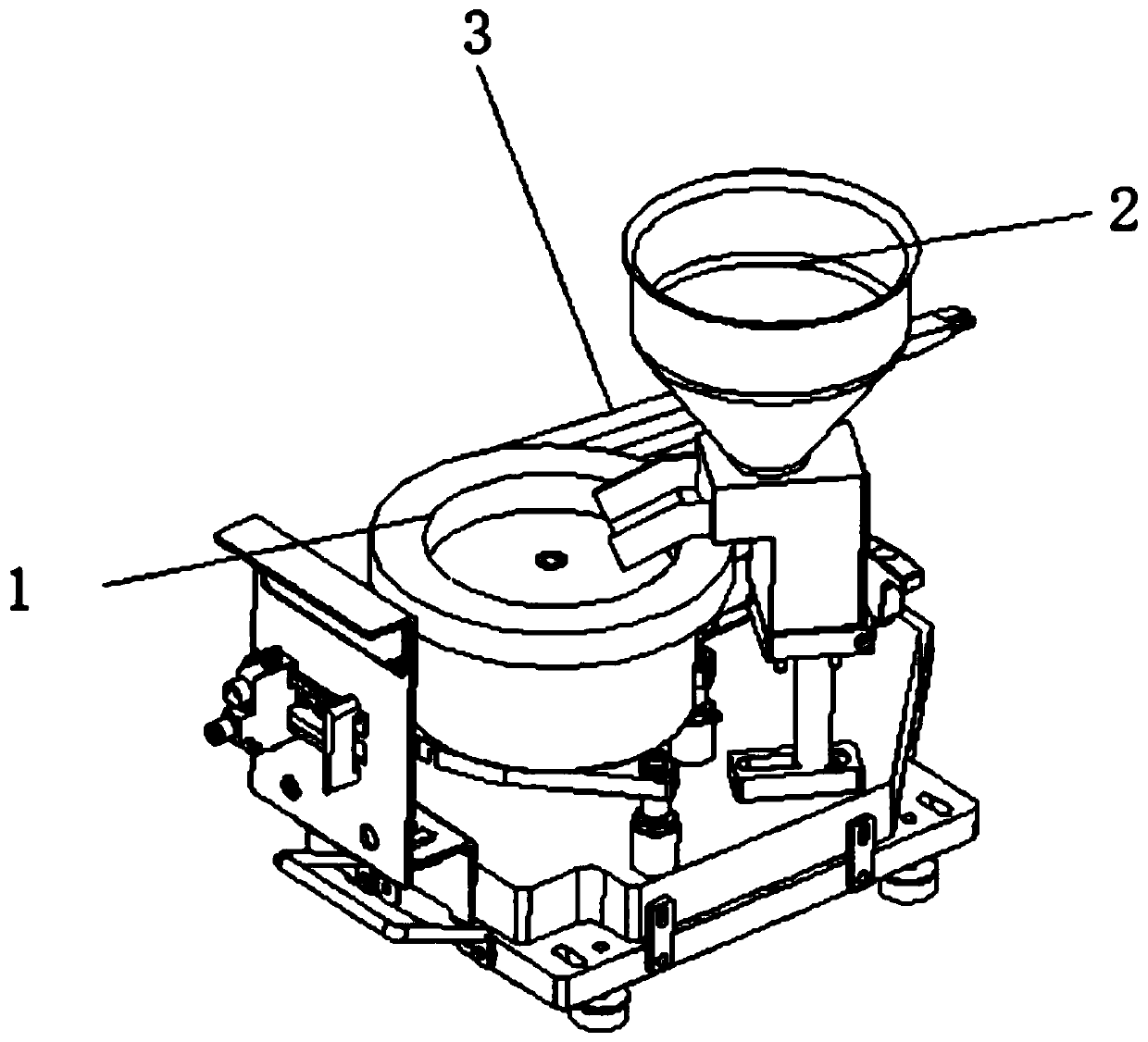

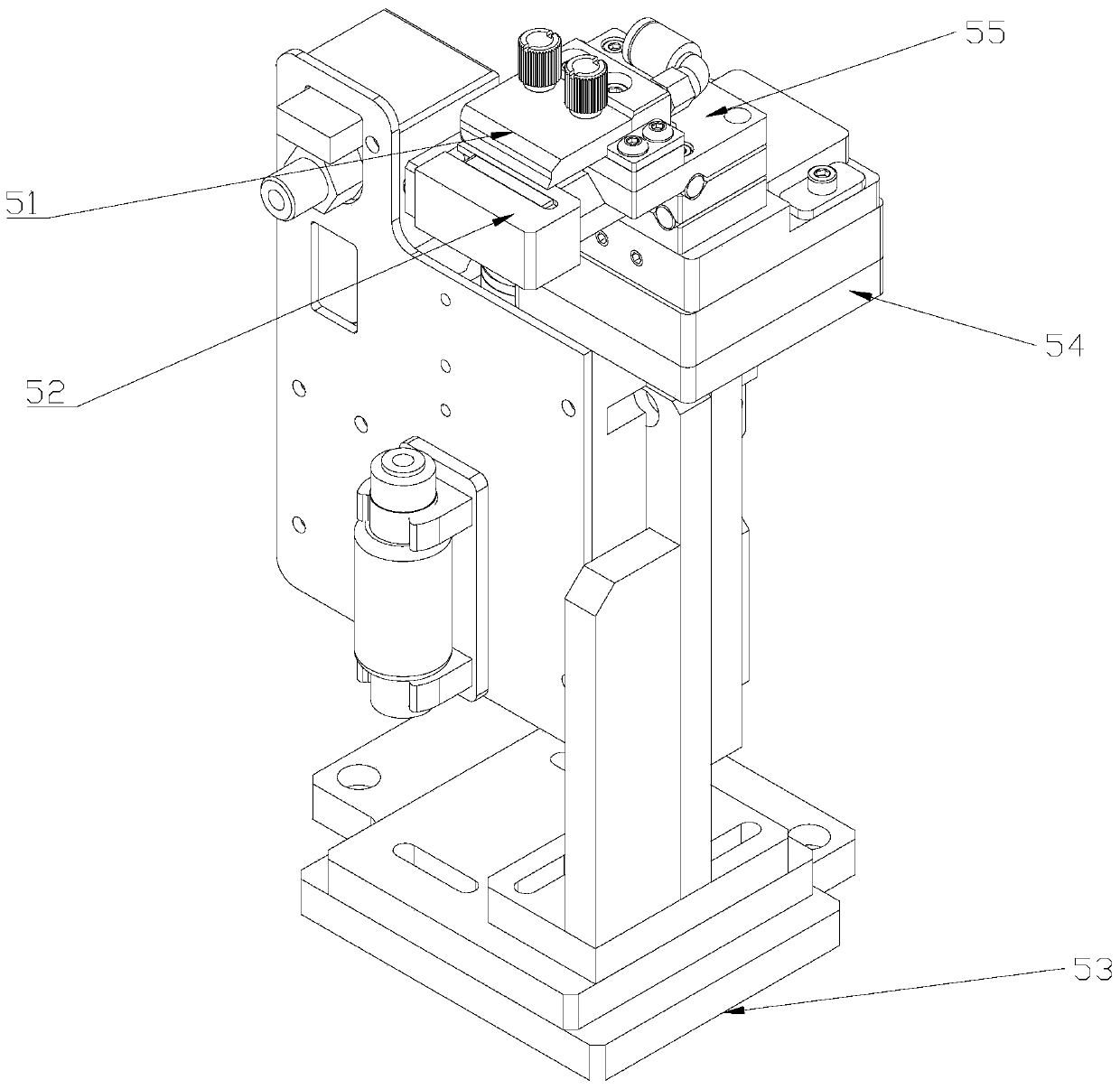

[0022] see Figure 1-7 As shown, the present invention relates to a six-sided visual detection and discharging sorting mechanism, a discharging mechanism, a detecting mechanism, and a sorting mechanism, wherein the detecting mechanism includes a fixed bottom plate, a turntable arranged on the surface of the fixed bottom plate and driven to rotate by a driving mechanism unit 4, wherein the detection mechanism also includes a tiny product guide unit 5 arranged on the surface of the fixed bottom plate and arranged in sequence along the circumference of the turntable unit 4, a photosensitive detection unit 6, a top view detection unit 7, a bottom view detection unit 8, Rear view detection unit 9, front view detection unit 10, right view detection unit 12, left view detection unit 13; the discharge mechanism includes a frequency modulation vibration vibration plate 1, and the upper side of the frequency modulation vibration vibration plate 1 is connected with a storage material mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com