Purified water preparation system and preparation method

A preparation system and technology for purifying water, which is applied in chemical instruments and methods, water treatment parameter control, water/sewage treatment, etc., can solve the problems of waste of water resources, waste of regenerants, start of regeneration, etc., so as to save waste of water resources , Improve operating efficiency and avoid excessive regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

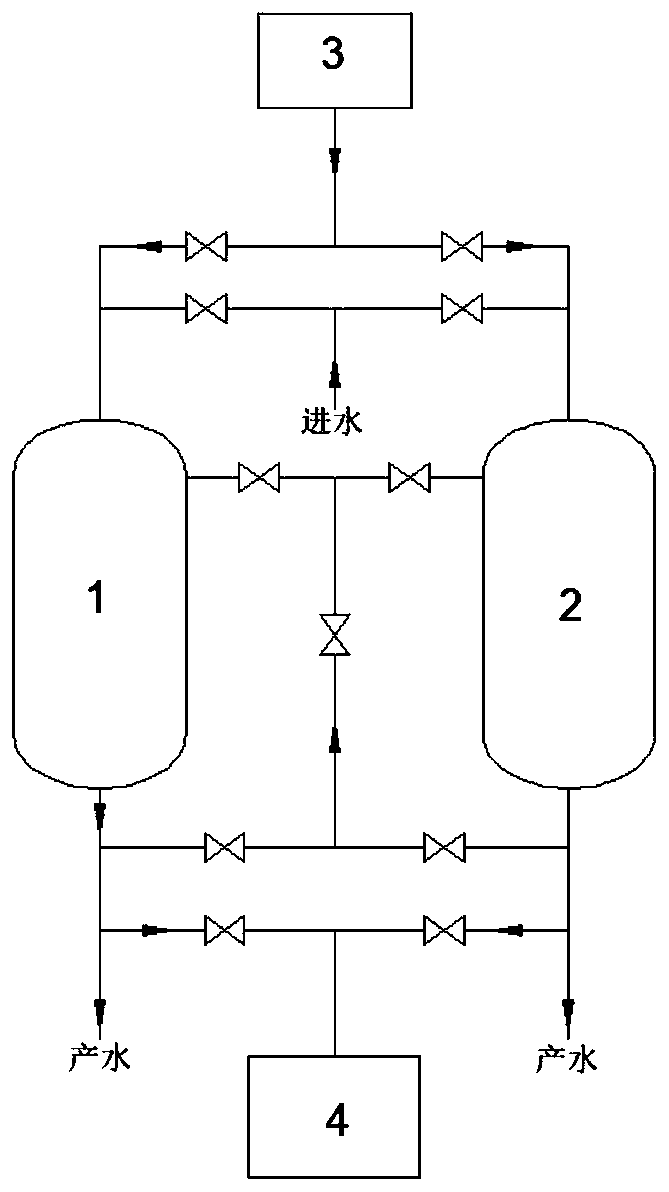

[0093] This embodiment provides a purified water preparation system, and the preparation system includes a softening unit and a filtering unit connected in sequence.

[0094] The softening unit includes a first softening device 1 and a second softening device 2 connected in series, and the water inlet of the first softening device 1 and the water inlet of the second softening device 2 are independently connected to the upstream water supply system. Along the direction of water flow, the water outlet of the first softening device 1 and the water inlet of the second softening device 2 are sequentially connected through the first series pipeline 5, and the water produced by the upstream water supply system enters the first softening device 1 for initial absorption and softening, and then passes through the first series connection. The pipeline 5 leads into the second softening device 2 , and the softened water obtained after the two-stage adsorption treatment enters the hardness t...

Embodiment 2

[0101] The method for preparing purified water using the purified water preparation system provided in Example 1 mainly includes two steps of softening treatment and filtration treatment. The softening treatment mainly removes calcium ions and magnesium ions in the product water of the upstream water supply system through the softening unit. The water produced in the upstream water supply system is softened to obtain softened water, and the filtration treatment is mainly to fine-filter the softened water through the filter unit to obtain purified water.

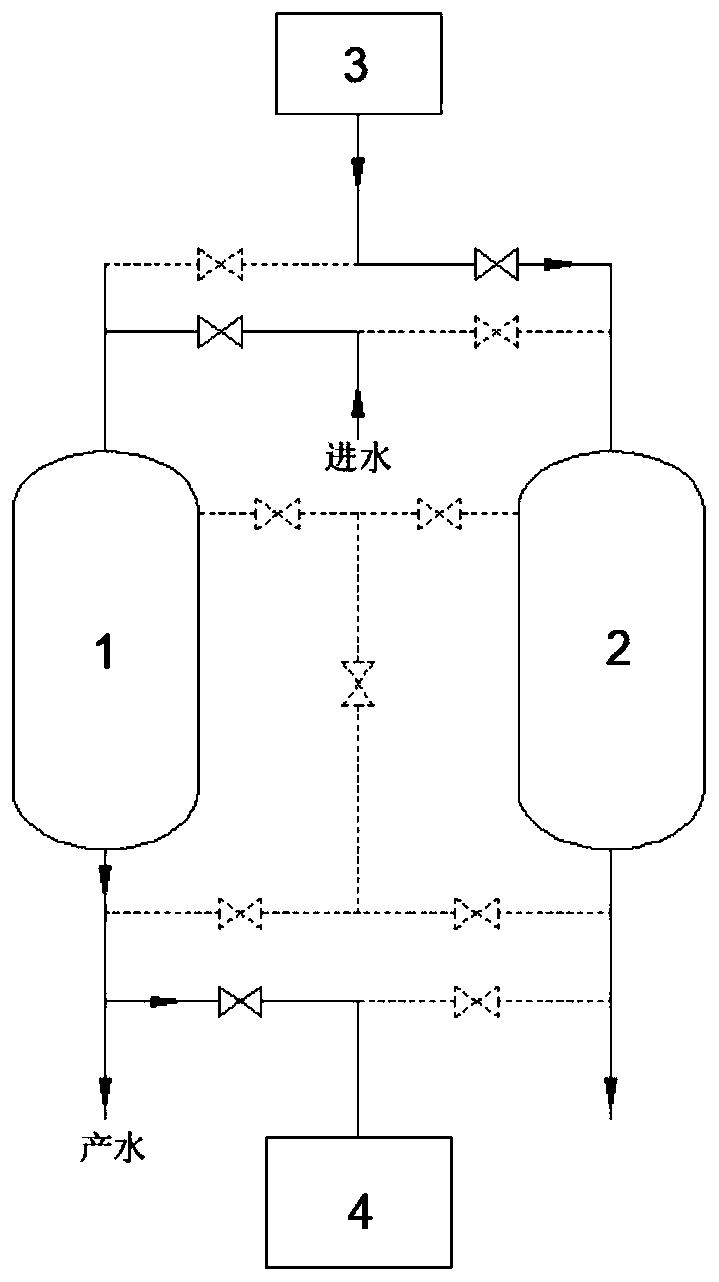

[0102] Specifically, in the softening process, the first softening device 1 and the second softening device 2 are alternately treated to absorb and soften the produced water of the upstream water supply system. figure 2 with image 3 , to describe the alternate processing route in detail:

[0103] Such as figure 2 As shown, the valve set on the dotted line pipeline is closed, and the valve set on the solid line pipeline i...

Embodiment 3

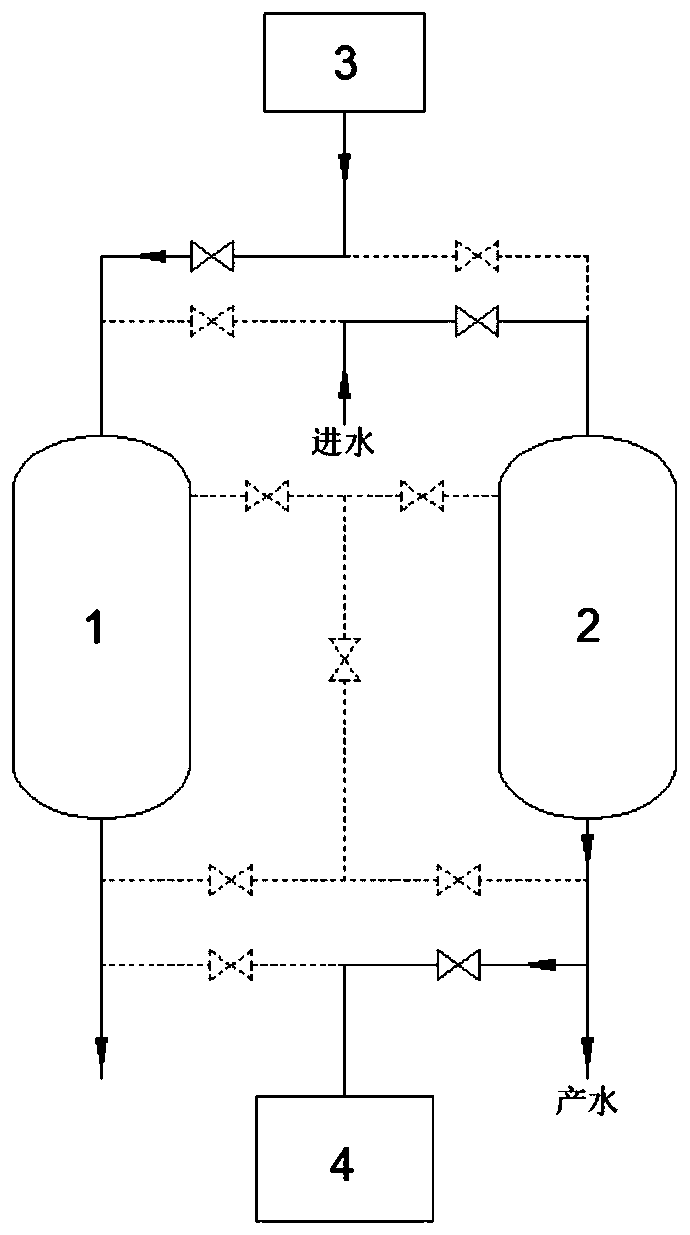

[0110] The method for preparing purified water using the purified water preparation system provided in Example 1 mainly includes two steps of softening treatment and filtration treatment. The softening treatment mainly removes calcium ions and magnesium ions in the product water of the upstream water supply system through the softening unit. The water produced in the upstream water supply system is softened to obtain softened water, and the filtration treatment is mainly to fine-filter the softened water through the filter unit to obtain purified water.

[0111] Specifically, the softening process adopts the process route of the first softening device 1 and the second softening device 2 in series to carry out adsorption and softening of the produced water in the upstream water supply system, which is combined below Figure 4 Detailed description of the serial processing route:

[0112] Such as Figure 4 As shown, the valve set on the dotted line pipeline is closed, and the va...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap