Particulate filter regeneration method, controller and regeneration system

A particle trap and regeneration system technology, which is applied in the electrical control of machines/engines and exhaust treatment devices, exhaust treatment, etc., can solve problems such as long service regeneration time, reduced engine operation stability, and low regeneration efficiency , to achieve the effects of environmental air protection, improvement of operational safety, and improvement of regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example ;

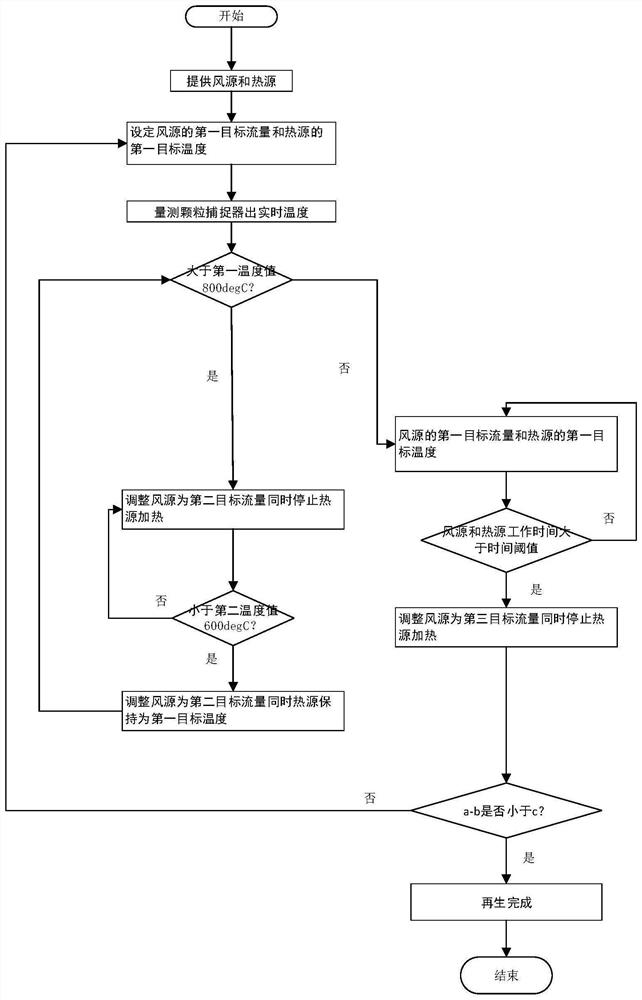

[0084] The invention provides a method for regenerating a particle trap, comprising the following steps:

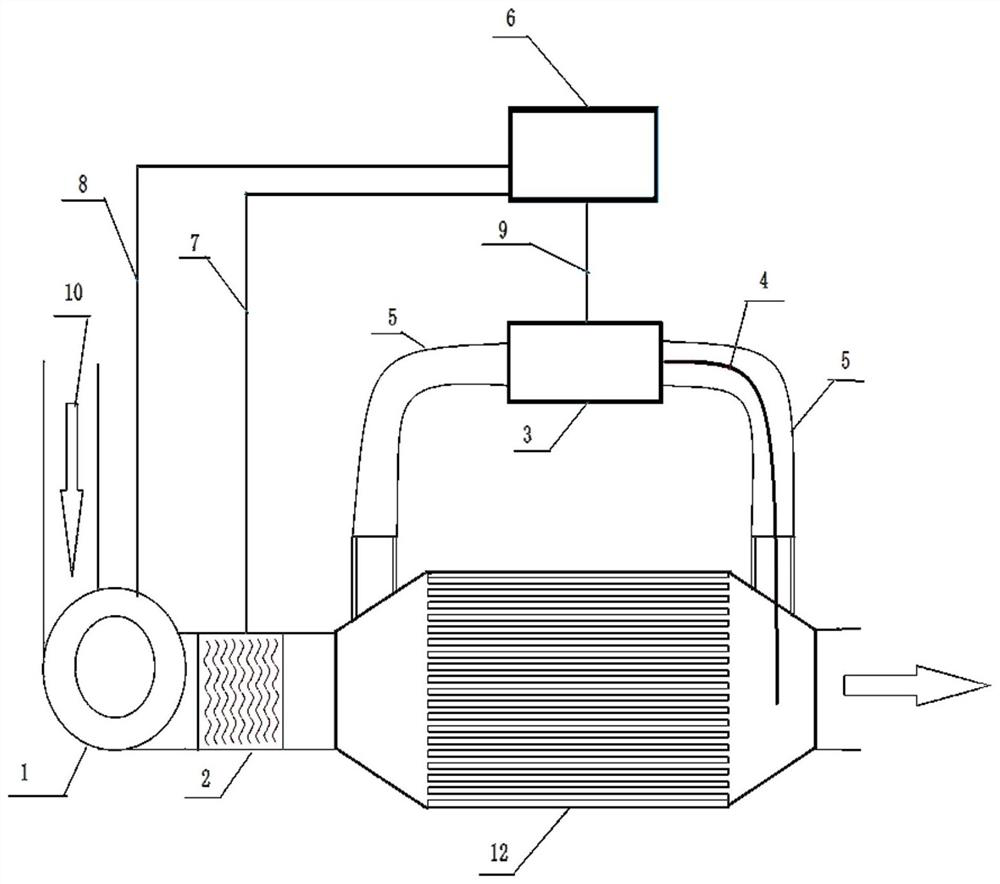

[0085] S1, providing air source and heat source, the air supplied by the air source is heated by the heat source and then enters the inlet of the particle filter;

[0086] S2. Measure the real-time temperature at the outlet of the particulate filter, adjust the target air volume of the air source and the target temperature of the heat source according to the real-time temperature until the regeneration condition of the particulate filter is met, otherwise readjust the target air volume of the air source and the target temperature of the heat source.

no. 1 example

[0087] In the first embodiment of the present invention, the regeneration time of the particle trap can be shortened and the regeneration efficiency can be improved under the environment of low oxygen content through the wind source and the heat source. Adjust the target air volume of the air source and the target temperature of the heat source according to the real-time temperature until the particle trap regeneration condition is satisfied, accurately control the regeneration time of the particle trap, avoid excessive regeneration of the particle trap, and avoid insufficient regeneration of the particle trap, Prevent wastage.

no. 2 example ;

[0089] Such as figure 1 As shown, the present invention provides a particle trap regeneration method, comprising the following steps:

[0090] S2.1, setting the first target flow rate of the wind source and the first target temperature of the heat source;

[0091] The first target flow rate and the first target temperature are specified according to actual needs. It is recommended that the first target flow range is less than 200Kg / h~400Kg / h, preferably less than 300Kg / h, and the first target temperature range is: greater than or equal to 650degC, preferably equal to 650degC;

[0092] S2.2, if the real-time temperature is greater than the first temperature value, adjust the air source to the second target flow rate and stop the heat source heating;

[0093] The first temperature value and the second target flow rate are specified according to actual needs. It is recommended that the first temperature value range is: greater than or equal to 800degC, preferably equal to 800de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com