Full-width seamless integrally-formed asphalt paving method for old road extension

An integral molding and asphalt technology, which is applied in roads, roads, buildings, etc., can solve the problems of vehicles changing lanes and shaking, multi-camber, horizontal and vertical flatness, etc., to achieve fuel-saving, labor-saving, and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

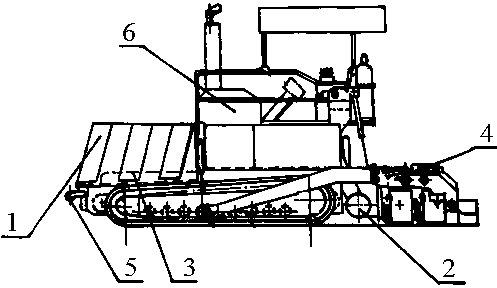

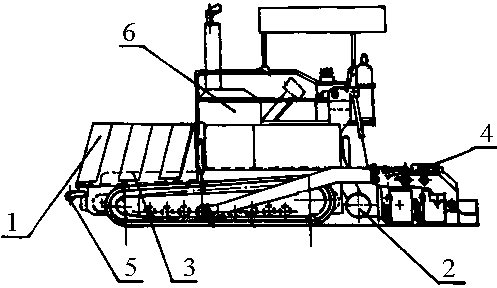

[0030] In order to solve the technical problems of multi-slope, multi-camber, rainy water accumulation, and swaying of vehicles caused by parallel machine paving in the prior art in the expressway reconstruction and expansion project, this embodiment provides a The full-width seamless integrated asphalt paving method for the expansion of the old road uses an anti-segregation paver to pave the old road and the new road at the same time to form a straight slope structure. During the asphalt paving process, according to the paving of the old road and the new road The difference in paving thickness adjusts the discharge volume of the two spiral paver 2 respectively, and adjusts the main vibration amplitude and auxiliary vibration amplitude of the anti-segregation paver to make the transverse compactness uniform, and realize the whole-width integrally formed asphalt pavement without longitudinal seams ;

[0031] Wherein, the anti-segregation paver includes a multi-stage telescopic ...

Embodiment 2

[0035] This embodiment provides a full-width seamless integral forming asphalt paving method for old road expansion, a full-width seamless integral forming asphalt paving method for old road expansion, using an anti-segregation paver to The old road and the new road are paved at the same time to form a straight slope structure. During the asphalt paving process, according to the difference in the paving thickness of the old road and the new road, the output volume of the two spiral paver 2 is adjusted respectively, and the anti-segregation paving is adjusted The main vibrating amplitude and auxiliary vibrating amplitude of the machine make the transverse compactness uniform, and realize the integral formation of asphalt pavement with no longitudinal seam in the whole width;

[0036] According to the difference in the paving thickness of the old road and the new road, the process of adjusting the discharge volume of the two feeding troughs is as follows: respectively adjust the ...

Embodiment 3

[0041] On the basis of Example 1, this example provides a full-width seamless monolithic asphalt paving method for the expansion of old roads. During the asphalt paving process, the anti-segregation paving is adjusted according to the paving thickness and initial compactness. The main vibration amplitude and auxiliary vibration amplitude of the paving machine.

[0042] In view of the different elevations and paving thicknesses of the new and old roads to be paved, the main vibration amplitude and the auxiliary vibration amplitude are adjusted according to the paving thickness of each section, so as to fill the old road with more material and tamp it strongly to ensure the compactness after compaction. Flatness after opening to traffic.

[0043] For the "four to eight" reconstruction and expansion project, the elevation and settlement of the new and old road surfaces are different, the thickness of the horizontal paving is different, and the initial density of the paving is dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com