High-low temperature alternating pure metal two-way sealing ball valve

A technology of two-way sealing ball valve and metal sealing ring, applied in valve details, valve device, valve shell structure, etc., can solve the problems of high production cost and maintenance cost, complex sealing structure, and many parts, so as to improve service life cycle, Improved wear resistance and high sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

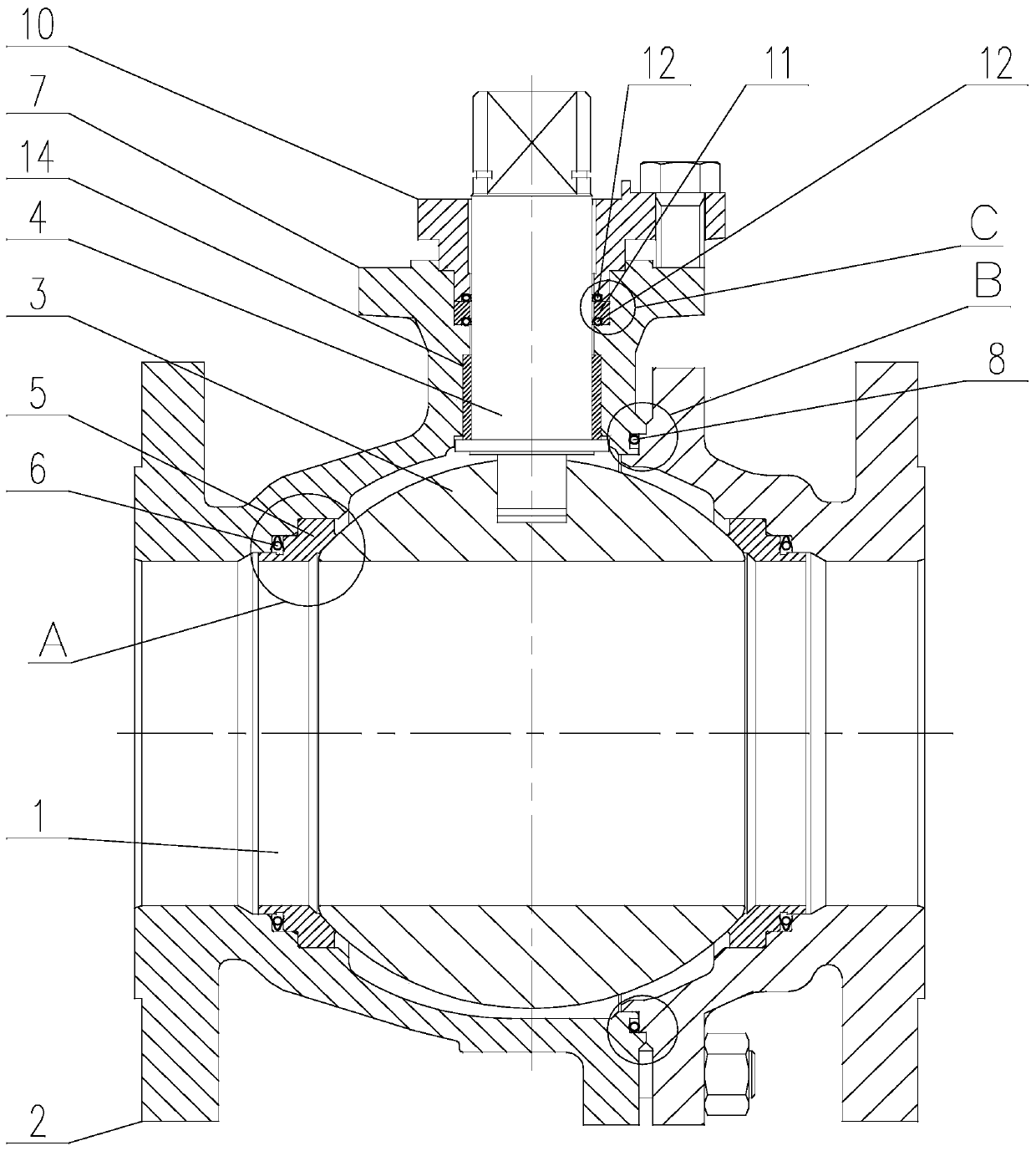

[0059] Such as Figure 1 to Figure 9 As shown, a high and low temperature alternating pure metal two-way sealed ball valve of the present invention includes a valve body 2 provided with a valve cavity 1, a ball 3 located in the valve cavity 1 and sealingly matched with the valve cavity 1 through a valve seat sealing pair, the The top of the sphere 3 is connected to the valve stem 4, preferably the valve stem 4 is flatly connected to the sphere 3. After the sphere is closed, the valve stem 4 does not bear the thrust of the medium in the valve cavity 1; Neck, the top of the valve stem 4 passes through the neck, and cooperates with the rotation and sealing of the neck. Manually or using a driving device to drive the valve stem 4 to rotate, so as to drive the ball 2 to rotate around the axis of the valve stem 4, so that the ball 2 Rotate within the range of 90° to realize the switch of the flow channel of the ball valve; there are two valve seat sealing pairs, which are respective...

Embodiment 2

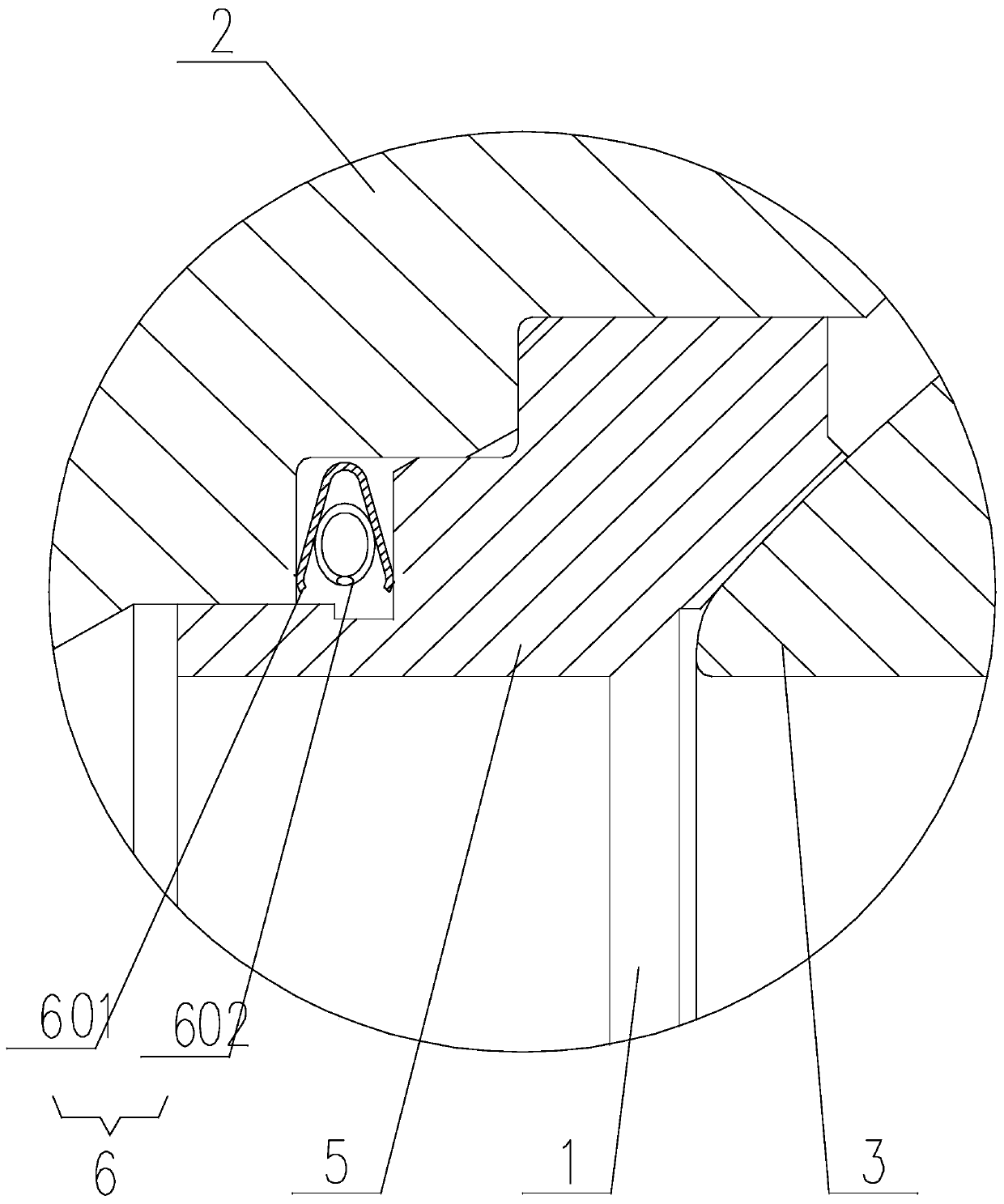

[0069] This embodiment is based on Embodiment 1, and describes the specific implementation structure of the spring-compensated metal sealing ring A6.

[0070] Such as figure 1 , figure 2 , Figure 5 , Figure 8 as well as Figure 9 As shown, in the present invention, the spring compensation type metal sealing ring A6 includes an outer elastic metal ring A601 and an inner compensation spring ring A602 whose axes both coincide with the axis of the flow channel, and the cross section of the outer elastic metal ring A601 is V shape, preferably its V-shaped opening faces the axis of the flow channel, and its two sides are respectively in contact with the end of the shaft shoulder and the bottom of the matching hole. The inner compensation spring ring A602 is installed on the outer elastic metal ring A601 In the V-ring groove, and in contact with the groove walls on both sides of the V-ring groove.

[0071] In the present invention, the unique structural design of the valve se...

Embodiment 3

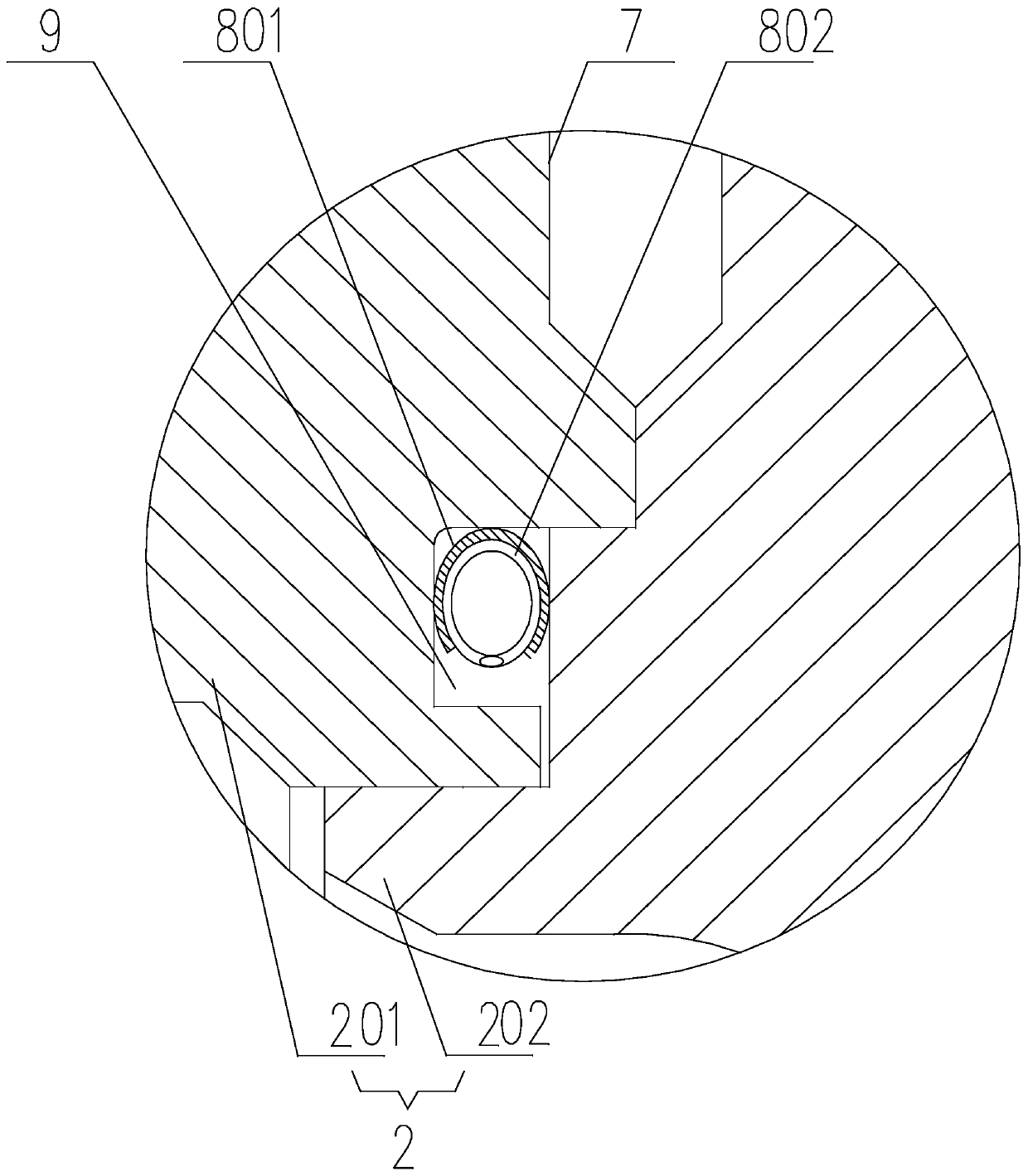

[0076] This embodiment is based on the above-mentioned embodiments, to further illustrate the structure of the valve body 2 .

[0077] Such as figure 1 As shown, in the present invention, the valve body 2 is divided into a left valve body 201 and a right valve body 202 by a plane perpendicular to the axis of the flow channel, and the valve cavity 1 is correspondingly divided into a left valve cavity and a right valve body located on the left valve body 201. The right valve chamber located on the right valve body 202, the ball center of the sphere 3 is located in the left valve chamber, and the top of the left valve body 201 protrudes into a neck 7 that is sealingly matched with the valve stem 4;

[0078] The left valve body 201 is detachably connected to the right valve body 202 through fasteners, and a spring is arranged between the left valve body 201 and the right valve body 202 to seal the divided parts of the left valve body 201 and the right valve body 202 Compensation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com