Oil drum waste heat utilization heating device capable of guaranteeing uniformity of oil film on surface of steel plate

A heating device and uniformity technology, which is applied in the field of oil tank waste heat utilization heating device, can solve the problems affecting the stamping production continuity of the main engine plant and the reduction of anti-rust ability, and achieve the effect of automatic control, convenient operation, and accurate mobile positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

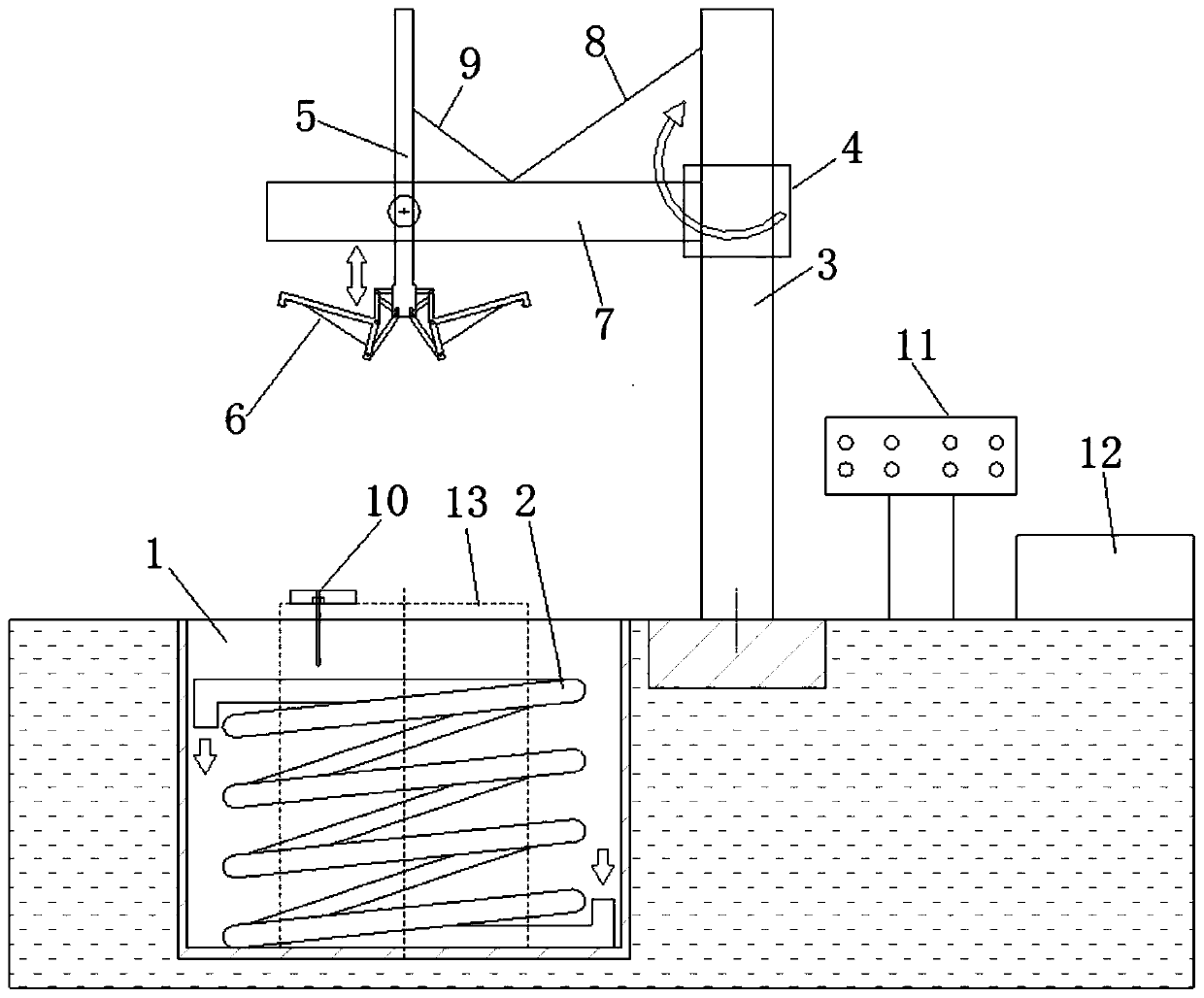

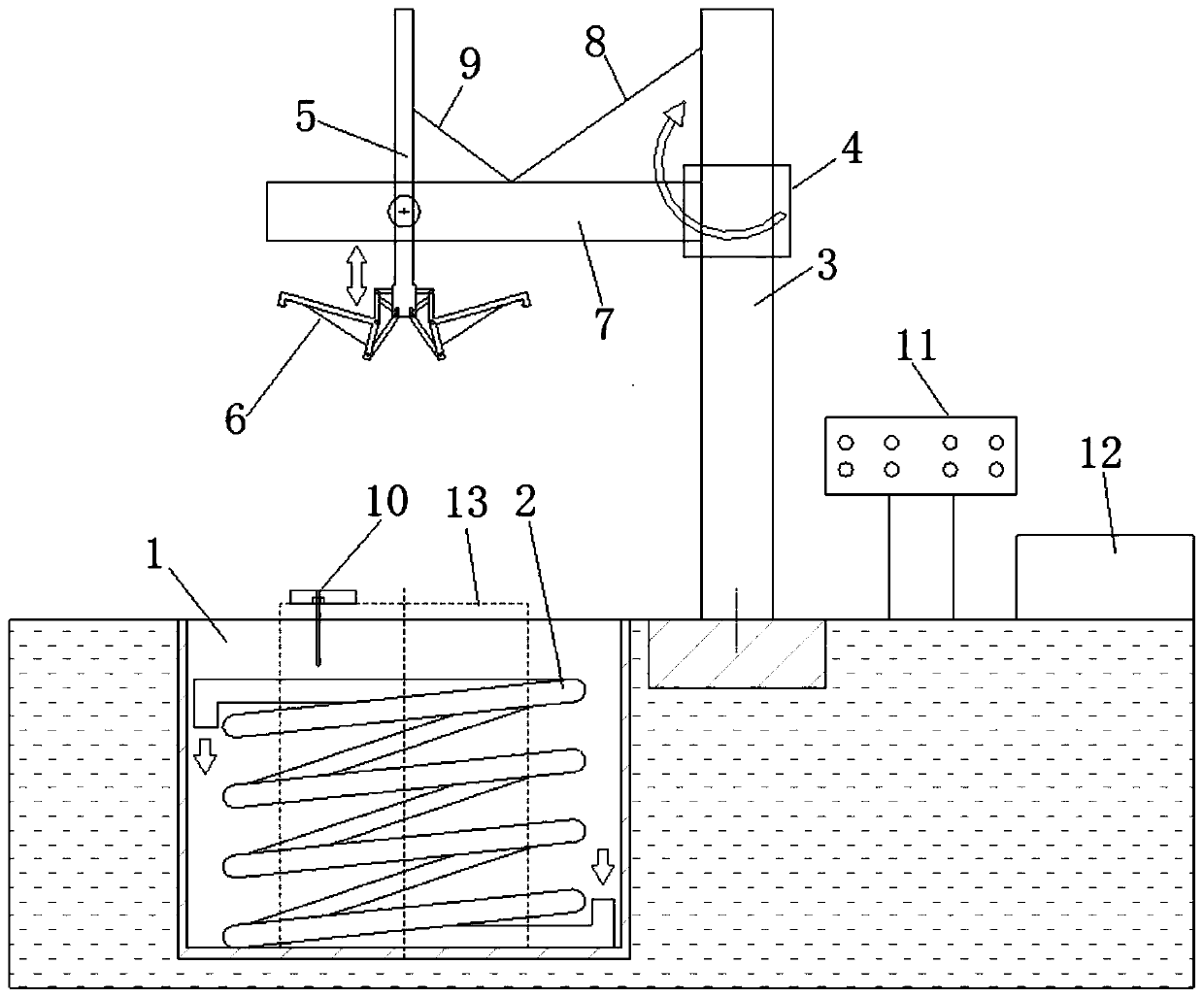

[0022] Such as figure 1 As shown in the present invention, a heating device for utilizing oil drum waste heat to ensure the uniformity of the oil film on the surface of the steel plate includes a spiral heat radiation tube 2, a column 3, a rotating mechanism 4, a lifting mechanism 5 and an oil drum clamping mechanism 6; The spiral heat radiation tube 2 is set in the pit 1, and the column 3 is set on the ground on one side of the pit 1, the upper part of the column 3 is set with a rotating mechanism 4, the lifting mechanism 5 is set on the rotating mechanism 4, and the oil drum clamping mechanism 6 is set At the bottom of the lifting mechanism 5, the oil drum clamping mechanism 6 is used to clamp the oil drum 13; the spiral heat radiation tube 2 is located below the moving path of the oil drum 13, and the inner diameter of the spiral heat radiation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com