Tension tester for pre-twisted hardware fitting

A tensile testing machine and hardware technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the lack of buffer mechanism and protection mechanism of the testing device, and the clamping of pre-twisted hardware is not firm, etc. problems, to achieve the effect of improving safety, improving practical convenience, and prolonging practical life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

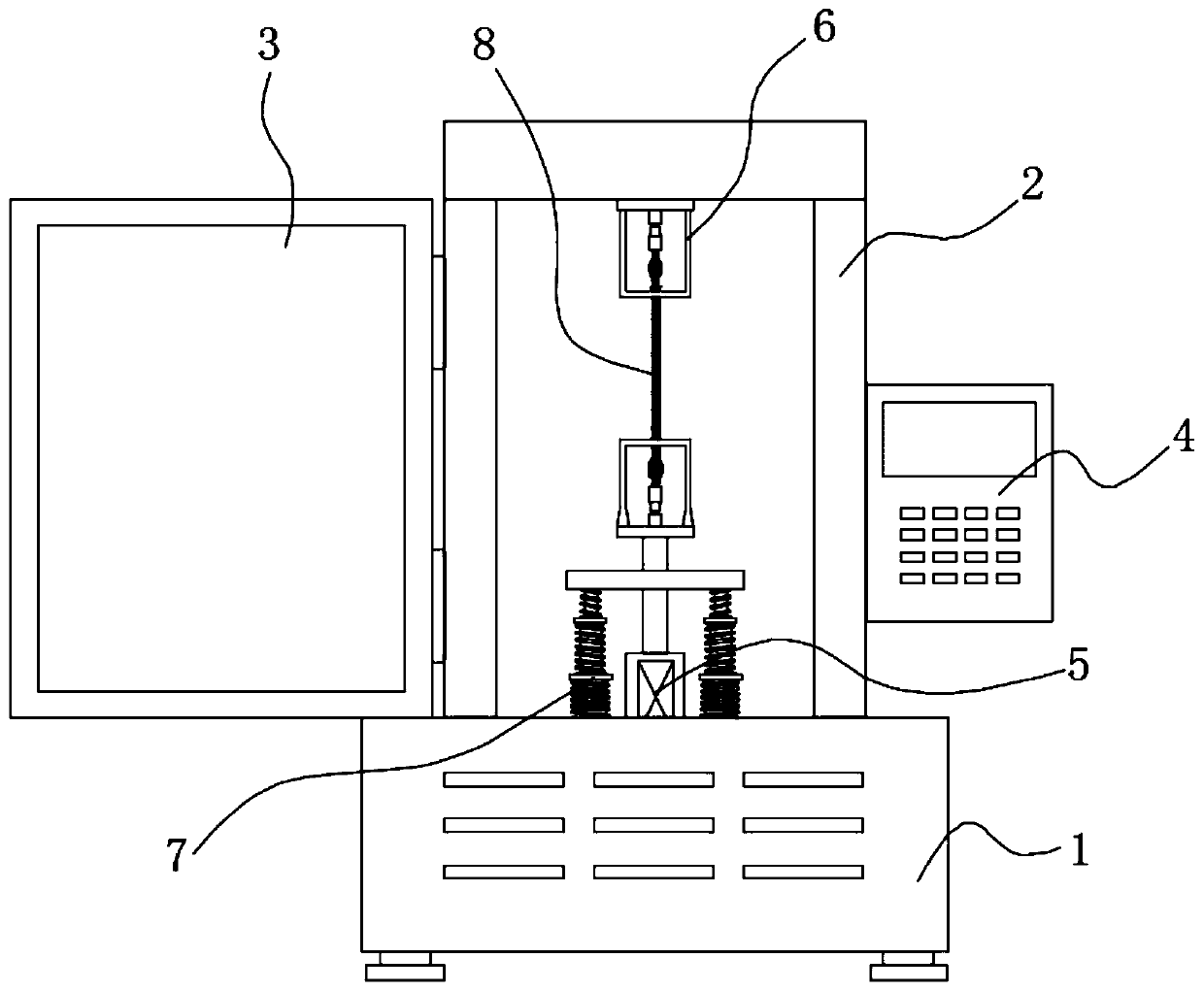

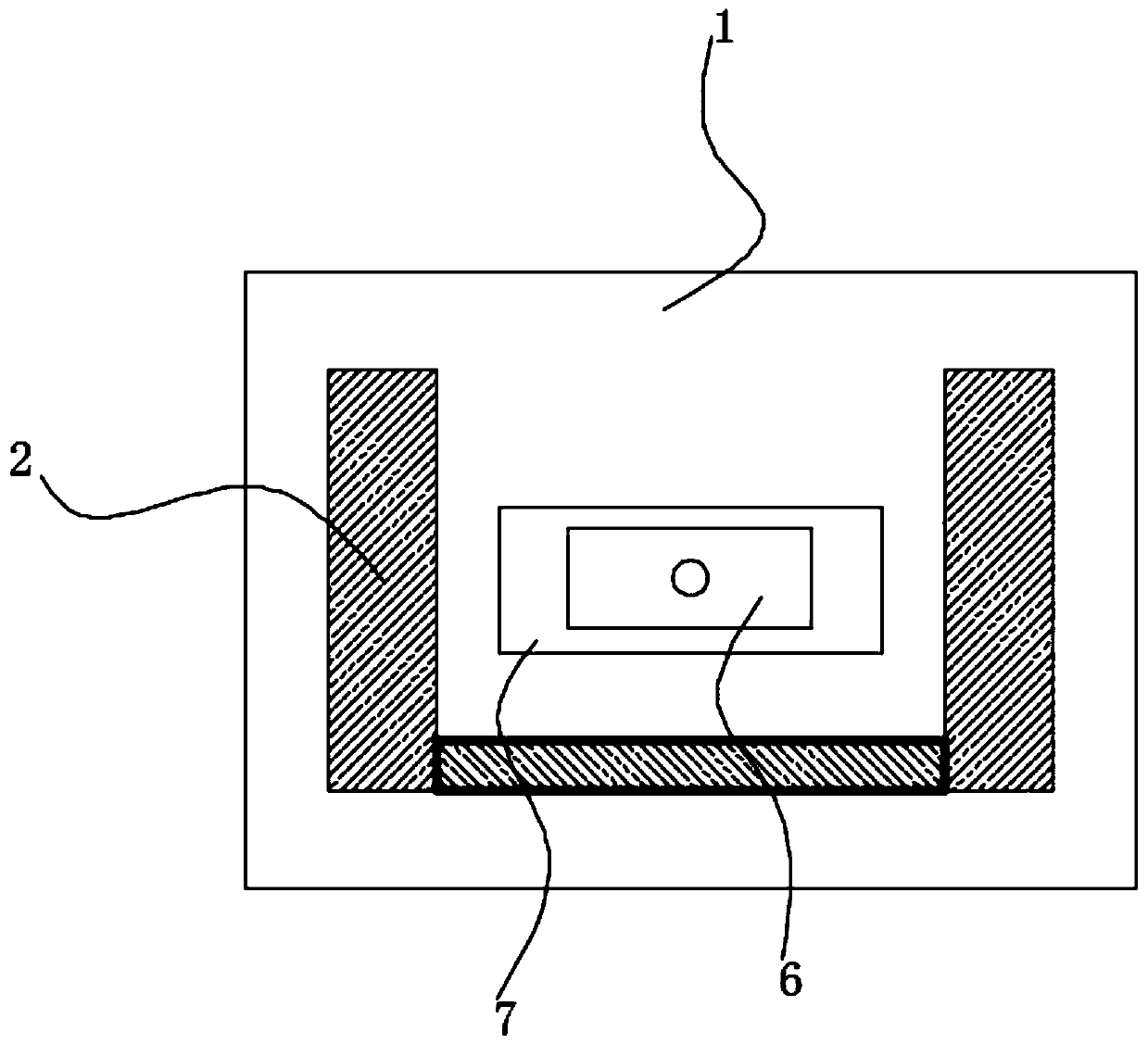

[0029] refer to Figure 1-5 , this embodiment relates to a tensile testing machine for pre-twisted metal fittings, comprising a base 1, a support frame 2, a protective door body 3 and a control device 4, the support frame 2 is fixedly installed on the base 1, and the control device 4 is fixedly installed on the support One side of the frame 2, the front side of the support frame 2 is equipped with a protective door body 3 by a hinge, the middle part of the base 1 is fixedly installed with a tension hydraulic rod 5 vertically facing the inside of the support frame 2, the piston rod upper end of the tension hydraulic rod 5 and The top of the support frame 2 is respectively equipped with corresponding test fixtures 6, the base 1 is located at the tension device 5 and equipped with a buffer protection mechanism 7, and a locking mechanism is arranged between the support frame 2 and the protective door body 3, the locking mechanism is Pins and pin holes.

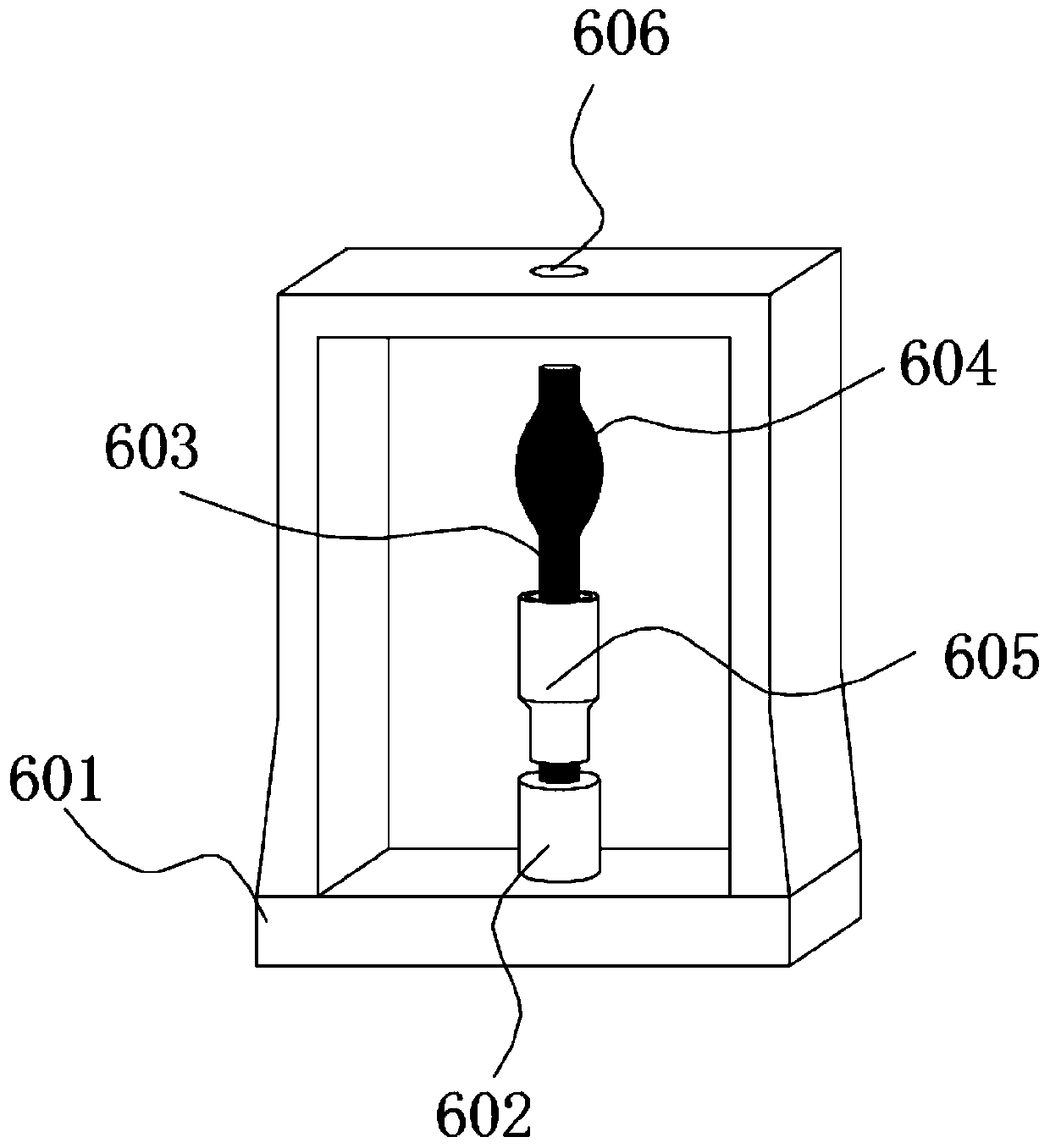

[0030] The test fixture 6...

Embodiment 2

[0037] refer to Figure 1-4, 6. The difference between this embodiment and the first embodiment is that the implementation of the buffer protection mechanism 7 is different. The second support rod 704 is a telescopic structure formed by connecting multiple groups of rod bodies in sequence. The base 1 on both sides of the tension hydraulic rod 5 is relatively telescopically equipped with a telescopic support rod 2 704, and the buffer plate 701 is fixedly installed on the two telescopic support rods 2 704. The upper end of each rod body of the telescopic support rod 2 704 is equipped with a buffer spring 2 705, and the middle part of the buffer plate 701 is provided with a through hole 606, and the piston rod of the tension hydraulic rod 5 passes through and is fixedly installed with a test fixture. 6. The elastic coefficient of the buffer spring 2 705 outside the telescopic support rod 2 704 increases sequentially from top to bottom.

[0038] In this embodiment, the telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com