Production line safety management system and method

A safety management and production line technology, which is applied in the field of safety management, can solve the problems that the operation of the emergency stop button cannot be traced in real time, the safety protection measures of the manual operation of the emergency stop button, and the emergency stop events of the production line cannot be sorted out and summarized in time, so as to improve the timeliness and intelligence, to achieve the effect of automatic security management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

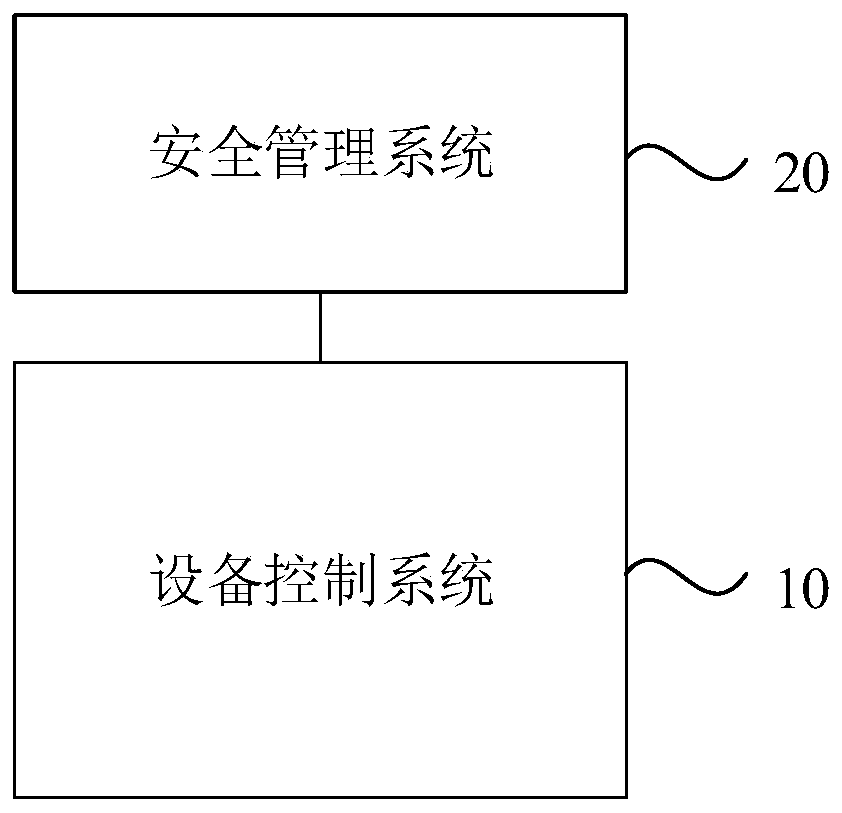

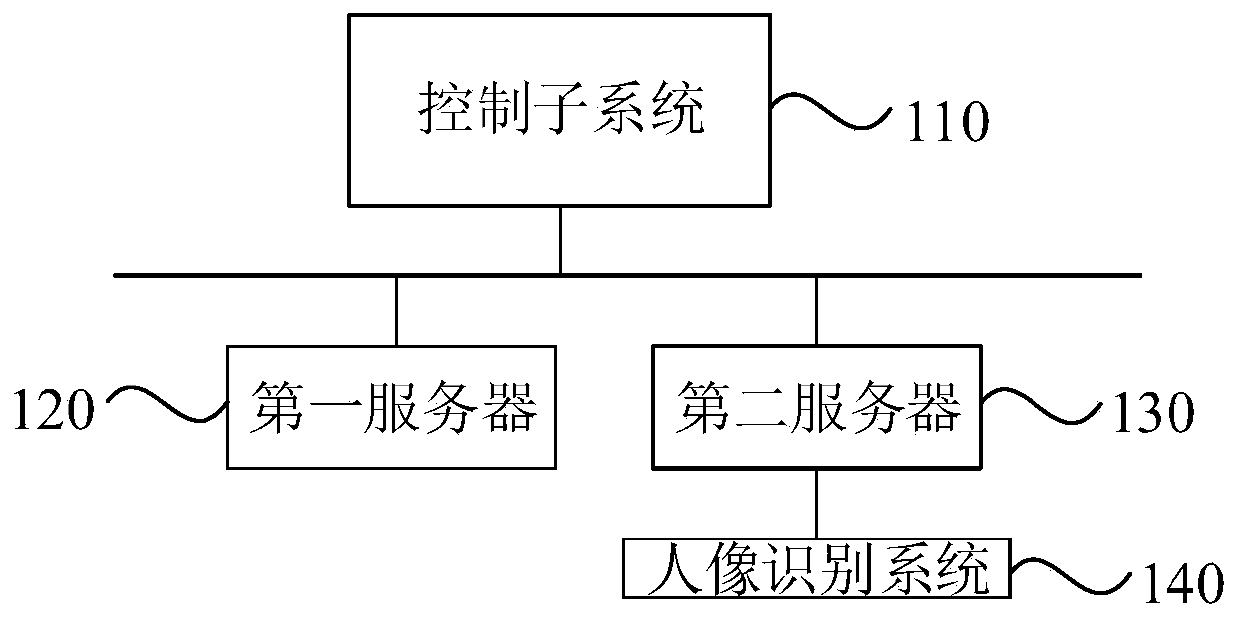

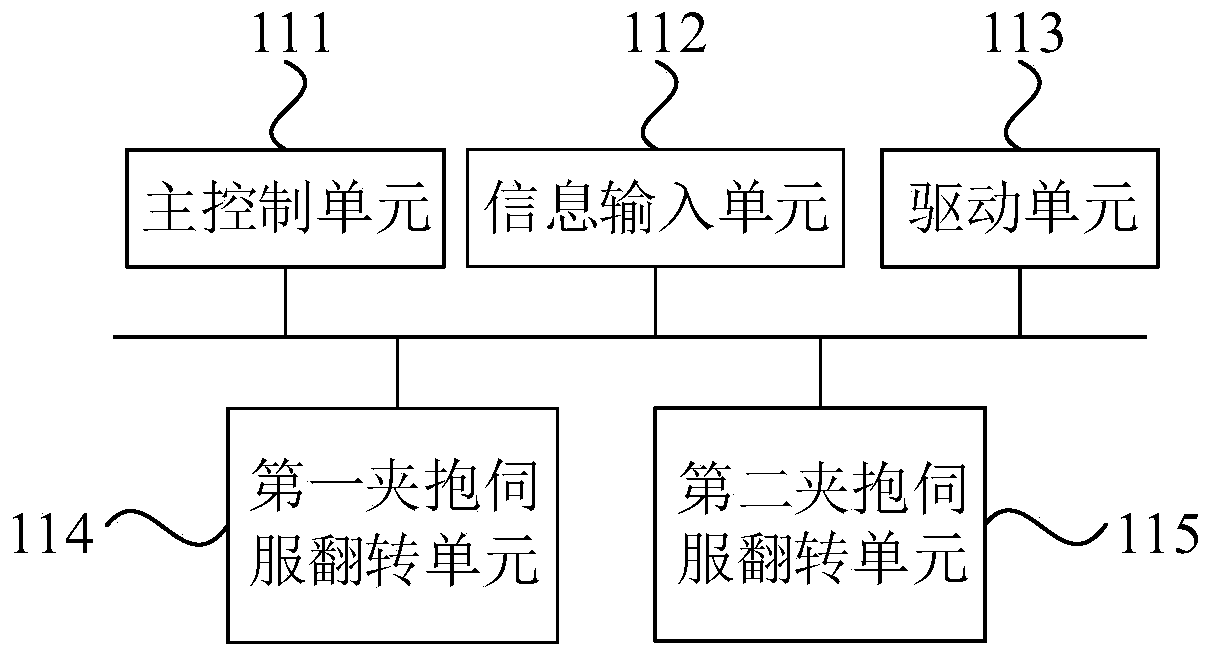

[0023] figure 1 It is a schematic diagram of a production line safety management system provided in Embodiment 1 of the present invention, as shown in figure 1 As shown, the structure of the production line safety management system may include: an equipment control system 10 and a safety management system 20; the equipment control system 10 and the safety management system 20 are connected in communication; wherein:

[0024] The equipment control system 10 is used to control all equipment in the production line; the safety management system 20 is used to monitor, protect and manage safety incident triggering events in the production process of the production line.

[0025] In the embodiment of the present invention, the structure of the production line safety management system may specifically include two main system structures of the equipment control system 10 and the safety management system 20 . Wherein, the equipment control system 10 can be used to control all the equip...

Embodiment 2

[0049] Figure 7 It is a flow chart of a production line safety management method provided by Embodiment 2 of the present invention. This method can be applied to the production line safety management system described in Embodiment 1 above to perform production line safety management automatically and intelligently. Correspondingly, such as Figure 7 As shown, the method includes the following operations:

[0050] S110. The equipment control system controls all the equipment in the production line.

[0051] S120. The safety management system monitors, protects and manages safety accident triggering events in the production process of the production line, and cooperates with the equipment control system to control all devices in the production line according to the safety accident triggering events.

[0052] In the embodiment of the present invention, when the safety management system detects a safety accident triggering event in the production process of the production line,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com