Aluminum electrolysis equipment full-life-cycle management system and repair method thereof

A technology of full life cycle and management system, which is applied in the whole life cycle management system of aluminum electrolysis equipment and the field of repair report, to achieve the effect of improving reliability and utilization rate, reducing maintenance cost and improving equipment return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will now be described with reference to the drawings. The present invention provides an aluminum electrolysis equipment life cycle management system and a repair method thereof, which are used to solve the current problems in equipment management in the aluminum electrolysis industry, but are not limited thereto.

[0024] The present invention will be described below in conjunction with the accompanying drawings.

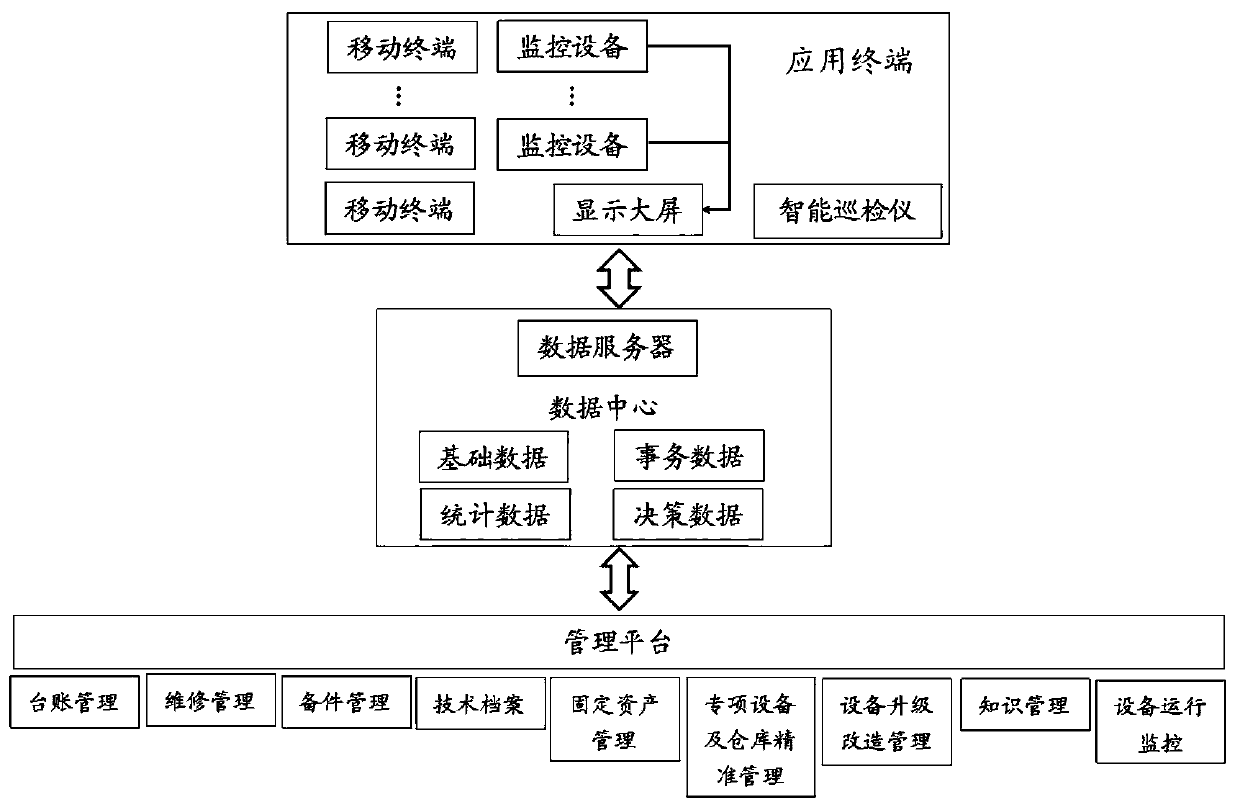

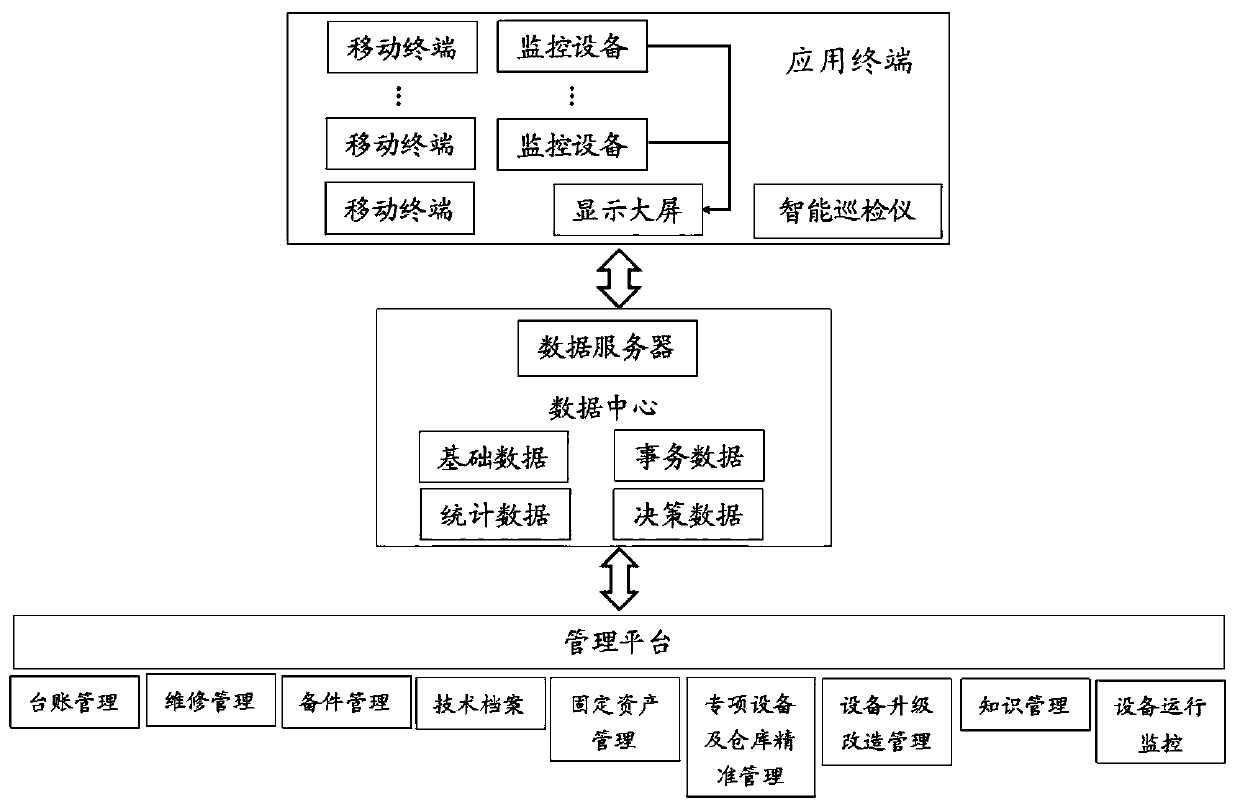

[0025] combine first figure 1 As shown, the present invention provides a whole life cycle management system for aluminum electrolysis equipment, the system includes platform functions, data centers and application terminals; wherein,

[0026] The system includes a management platform, a data center and an application terminal; wherein,

[0027] The management platform is used for ledger management, maintenance management, spare parts management, technical files, fixed assets management, special equipment and warehouse pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com