Assembled power distribution cabinet

A power distribution cabinet and assembled technology, applied in substation/power distribution device casing, electrical components, substation/switch layout details, etc., can solve the problem of inapplicability of power distribution cabinet, incompatibility between electrical parts and power distribution cabinet body Matching and other issues, to achieve the effect of high heat dissipation efficiency, good overall structural strength, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

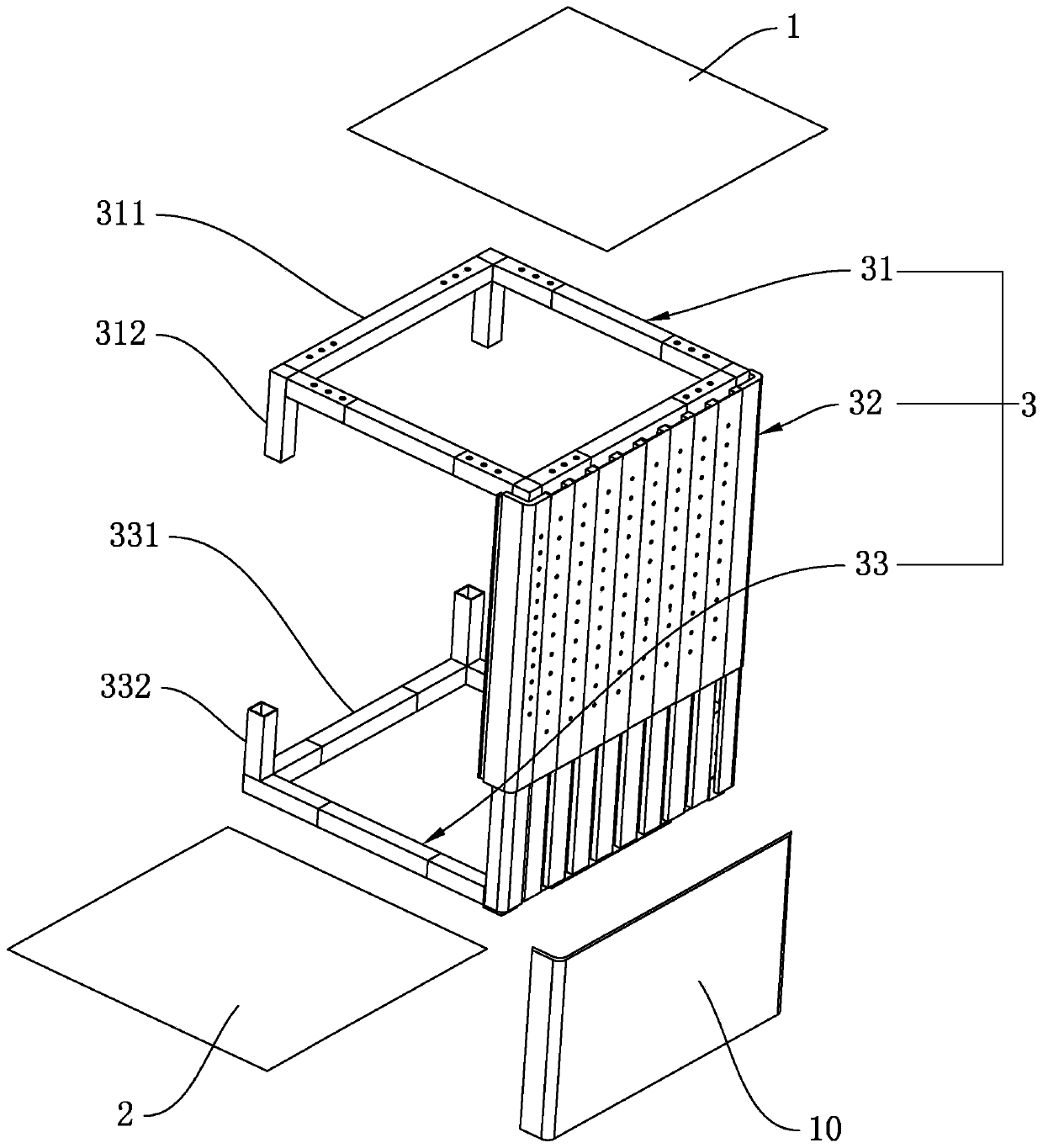

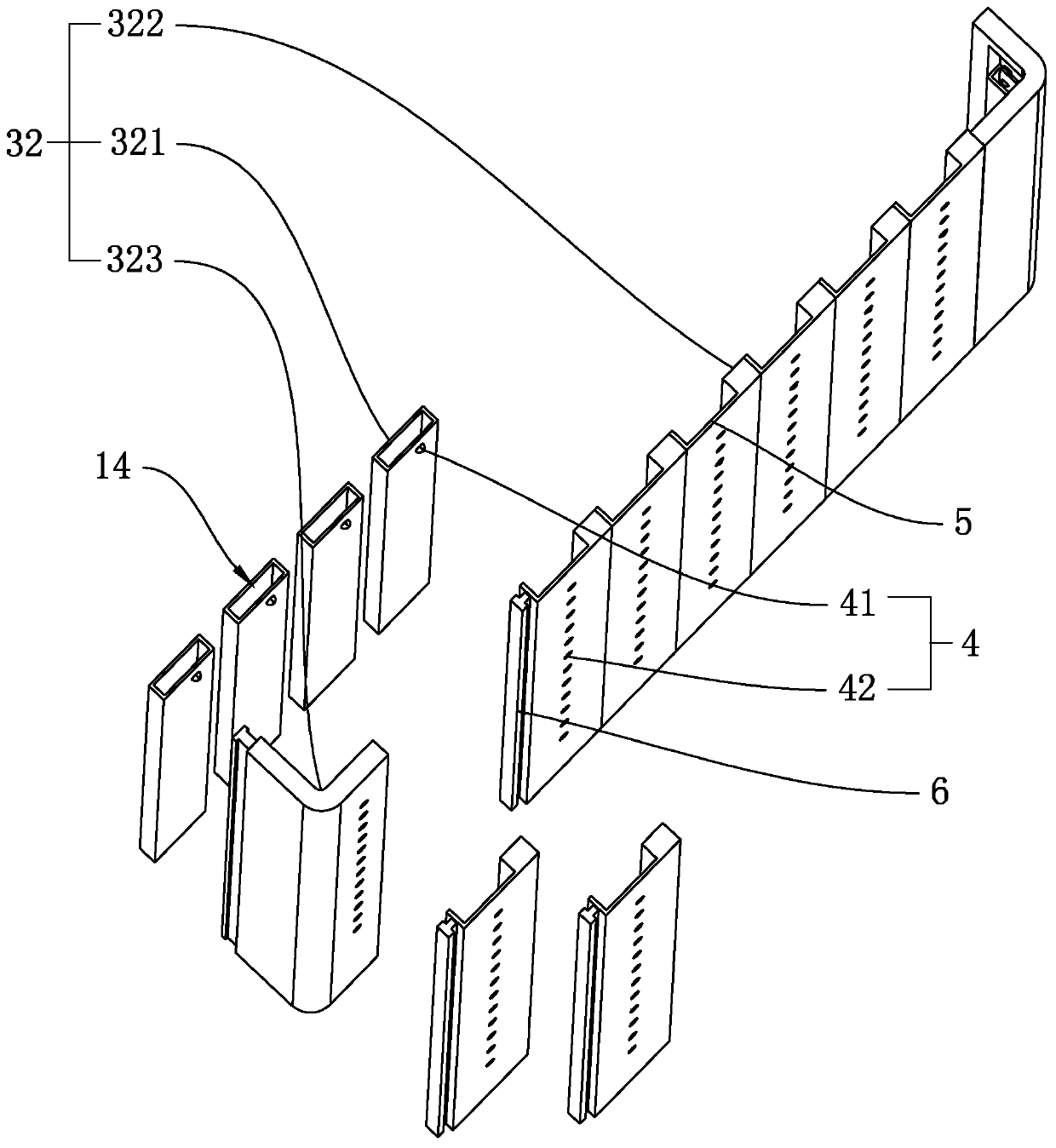

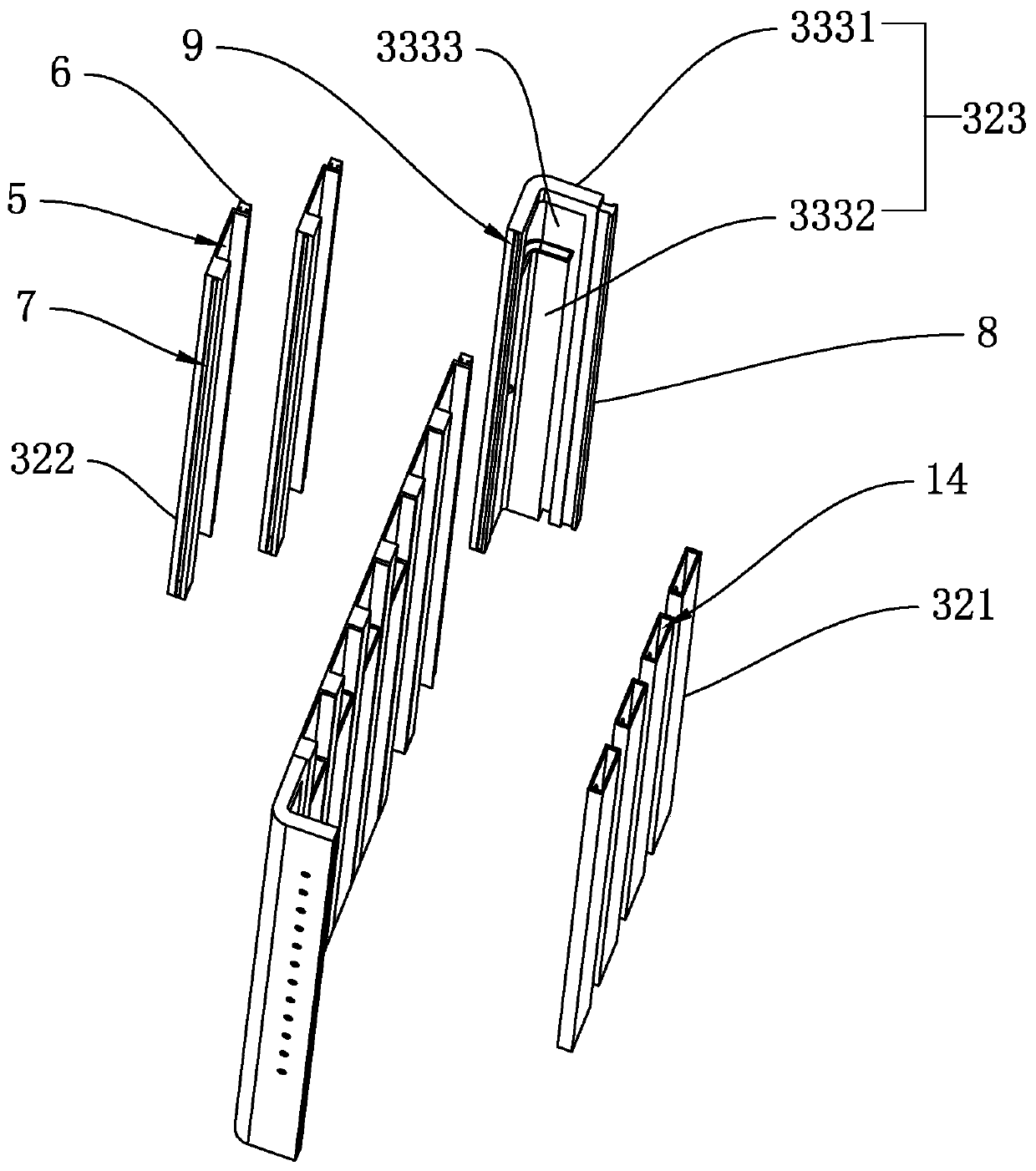

[0038] Example: refer to figure 1 , is an assembled power distribution cabinet disclosed in the present invention, which includes a rectangular parallelepiped cabinet body 3 , and the cabinet body 3 includes an upper cabinet frame 31 , a lower cabinet frame 33 and a side panel assembly 32 . The upper cabinet frame 31 includes four upper frame bars 311 connected end to end to form a square frame body. The four corners of the upper cabinet frame 31 are integrally formed with an upper frame leg 312 corresponding to each corner, and the upper frame leg 312 is perpendicular to the upper cabinet The bottom surface of the frame 31, the top of the upper cabinet frame 31 is fixedly provided with an upper panel 1, and the upper panel 1 is welded and covered on the top surface of the upper cabinet frame 31; Frame bar 331, the upper cabinet frame 31 and the lower cabinet frame 33 have the same shape and size, and the four corners of the lower cabinet frame 33 are integrally formed with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com