Quick stripping device applicable to power cables with different thickness specifications

A power cable, thickness technology, applied in the direction of cable installation, cable installation device, dismantling/armouring cable equipment, etc., can solve the problems of unsuitable small workshop processing cost, low stripping efficiency, different cable thickness specifications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

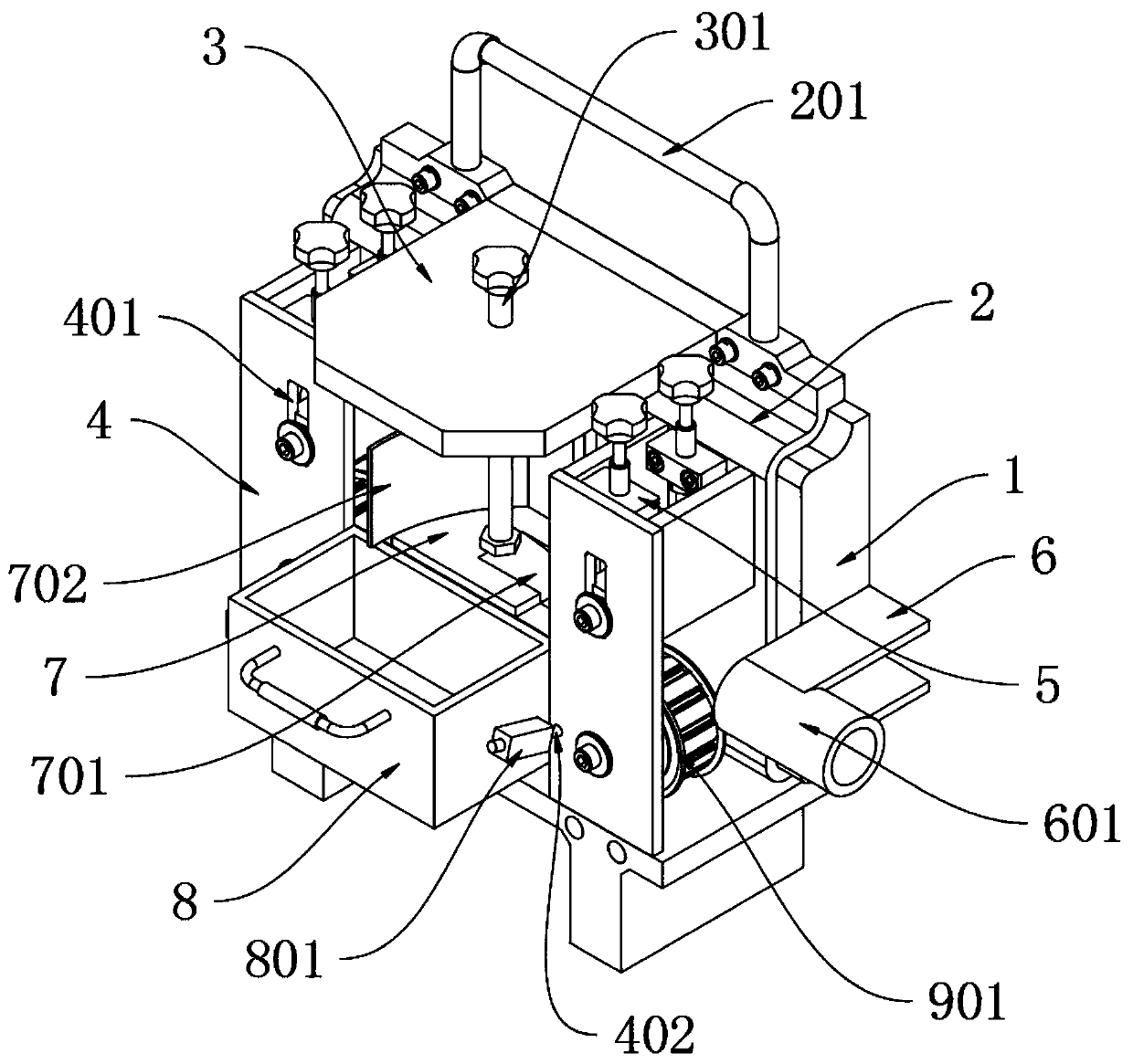

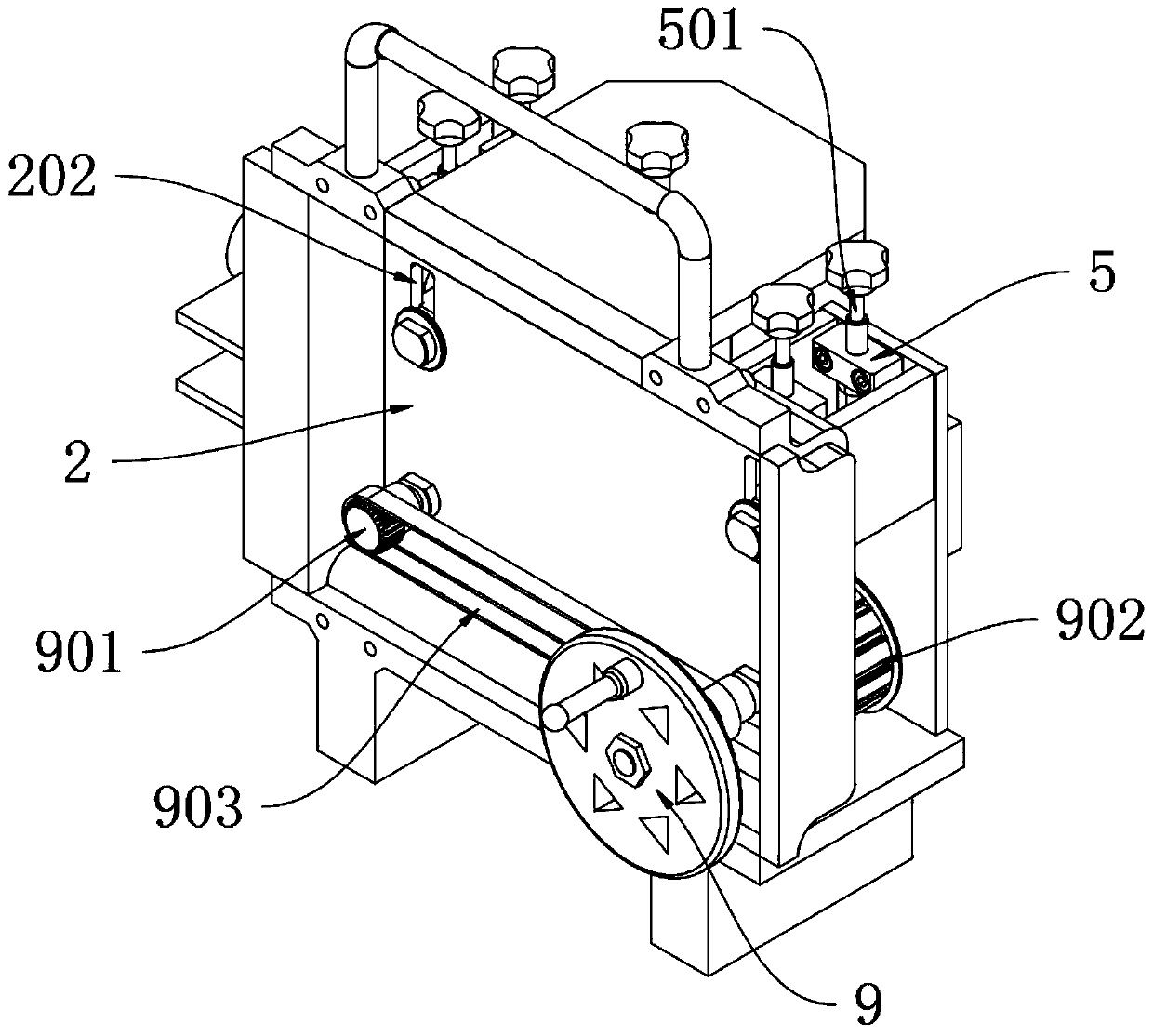

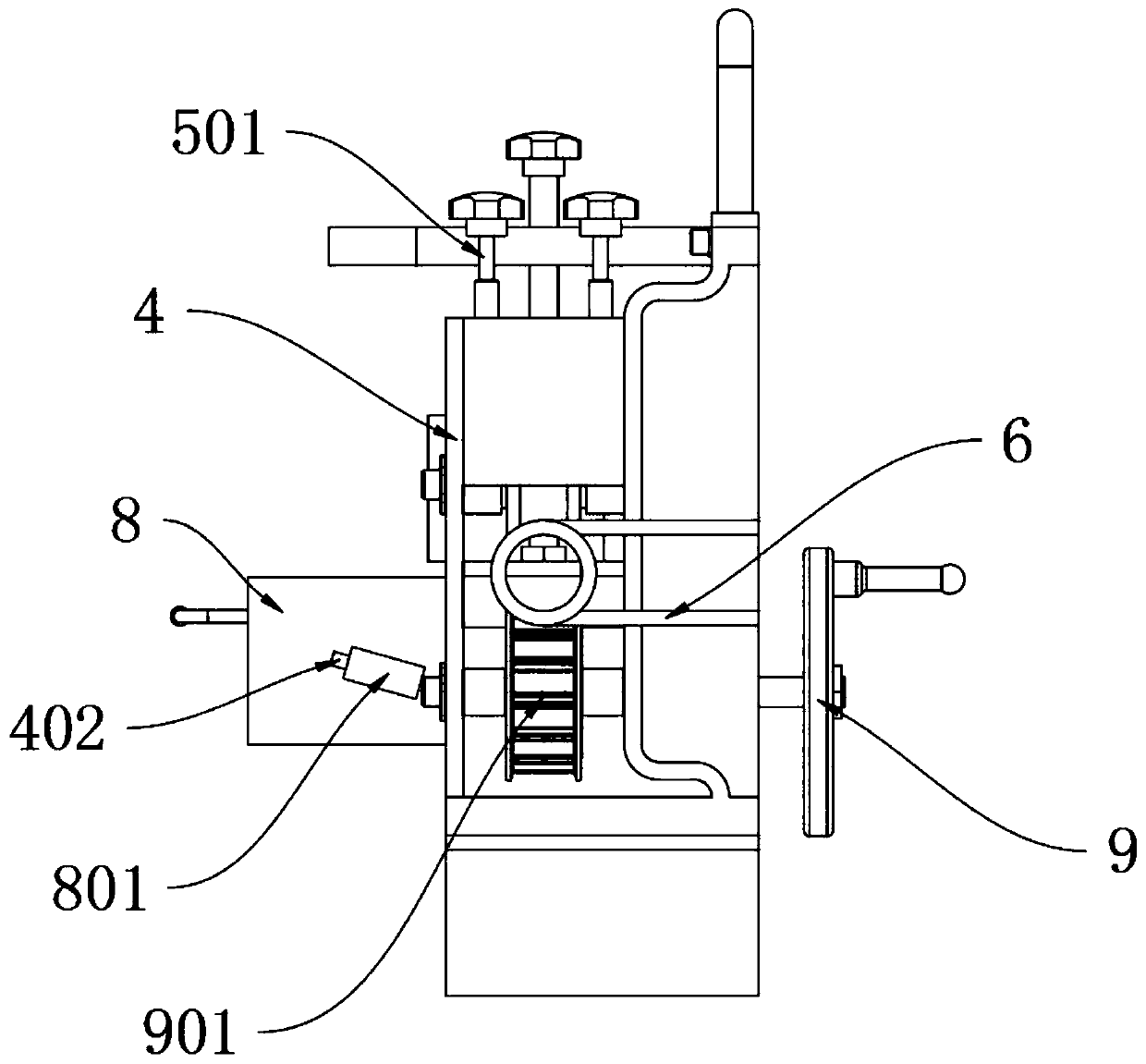

[0036] as attached figure 1 to attach Figure 8 Shown:

[0037] The present invention provides a fast and applicable stripping device for power cables of different thickness specifications, which includes a box frame main body 1; a rear end edge of the box frame main body 1 is fixed vertically upward with a back plate 2; a front edge of the box frame main body 1 is vertically upward Two side protection mechanisms 4 are symmetrically installed; the middle part of the upper end of the back plate 2 is fixed vertically forward with a blade adjustment mechanism 3; the lower end of the blade adjustment mechanism 3 is horizontally equipped with a stripping mechanism 7; the back plate 2 below the stripping mechanism 7 A tray 10 is vertically fixedly installed on the top; a waste bin 8 is installed on the box frame main body 1 in front of the tray 10; Between the backboard 2; between the upper end of the backboard 2 and the upper end of the side protection mechanism 4, a vertical pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com