A method for improving the suspension of pellet fish feed

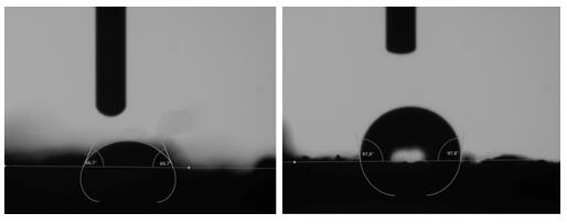

A pellet feed and suspension technology, which is applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve the problems that it is difficult to improve the surface hydrophobicity of pellet feed, so as to reduce the loss of soluble vitamins and have good suspension , the effect of reducing surface hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

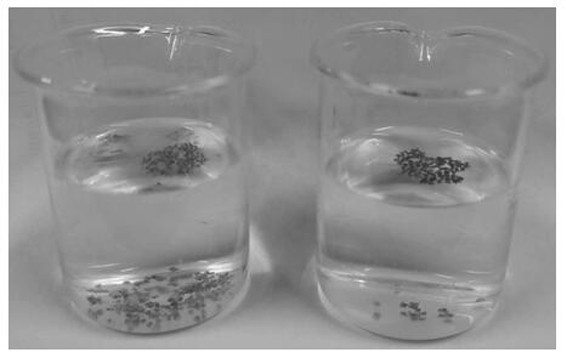

Embodiment 1

[0023] Add 1 part of gelatin, 1 part of Span 80 and 1 part of malic acid to 100 parts of water, 70 o Stir under C to form a uniform natural colloid solution; 10 parts of lard and 15 parts of corn oil are mixed, 70 o C forms mixed oil; Mixed oil is added in the above-mentioned natural colloid solution, forms homogeneous emulsion under stirring at 300 rpm; Above-mentioned emulsion is mixed at 50 o C is sprayed onto the surface of 50 parts of pellet feed, 70 o C was dried for 4 hours to obtain a modified suspended particle feed. Suspension of pellet feed in water for 8h.

Embodiment 2

[0025] Add 3 parts of guar gum, 1 part of OP-10 and 1 part of acetic acid to 100 parts of water, 60 o Stir at C to form a homogeneous natural colloid solution; 5 parts of hydrogenated vegetable oil and 15 parts of soybean oil are mixed, 60 o C forms mixed oil; Mixed oil is added in the above-mentioned natural colloid solution, forms homogeneous emulsion under stirring at 500 rpm; Above-mentioned emulsion is mixed at 60 o C is sprayed onto the surface of 100 parts of pellet feed, at 60 o C and dried for 6 hours to obtain a modified suspended particle feed. Suspension of pelleted feed in water for 4 h.

Embodiment 3

[0027] Add 5 parts of flax gum, 2 parts of cetyltrimethylammonium bromide and 3 parts of citric acid to 100 parts of water, 80 o Stir under C to form a uniform natural colloid solution; mix 3 parts of beeswax and 10 parts of linseed oil at 80 o C forms a mixed oil; the mixed oil is added to the above-mentioned natural colloid solution, and a homogeneous emulsion is formed under stirring at 1000 rpm. Put the above emulsion at 80 o C is sprayed onto the surface of 80 parts of pellet feed, at 80 o C and dried for 2 hours to obtain the modified suspended particle feed. Suspension of pelleted feed in water for 12 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com