Soil ecological remediation device for industrial land

An ecological restoration and soil technology, applied in the field of soil restoration, can solve the problems of easy agglomeration and hardness of soil, inability to crush soil, serious soil pollution of industrial land, etc., and achieve the effect of sufficient mixing and improving restoration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

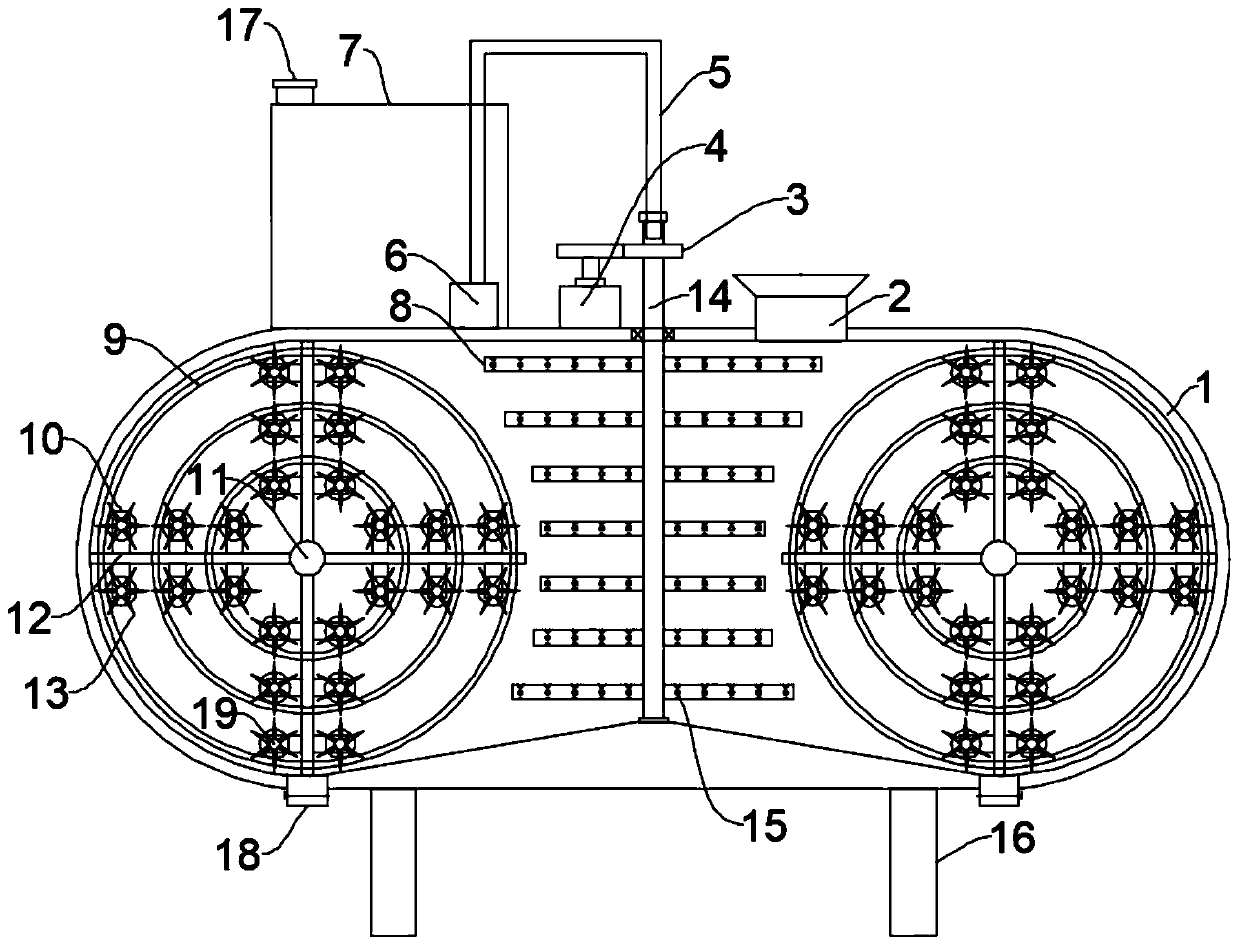

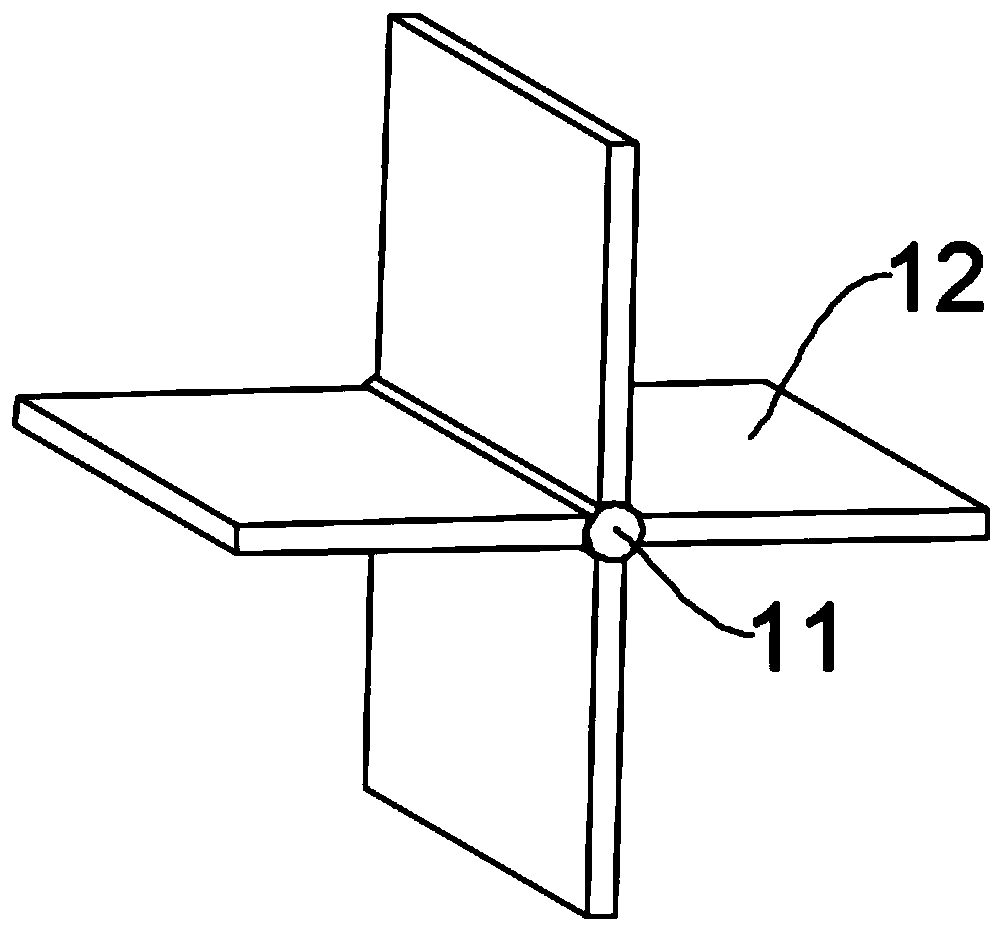

[0024] see Figure 1~2 , in an embodiment of the present invention, an industrial land soil ecological restoration device includes a box body 1, a mixing unit and a liquid supply unit, the left and right side walls of the box body 1 are in the shape of a semicircle, and the bottom of the box body 1 is evenly and symmetrically fixed and installed with Support legs 16, the top of the box body 1 is provided with a feed hopper 2, both ends of the bottom of the box body 1 are provided with a discharge port 18, and a valve is installed on the discharge port 18, and the bottom of the inner cavity of the box body 1 is from the middle to both sides. The discharge port 18 is arranged obliquely to facilitate discharging. The mixing unit includes a pulverizing mechanism and a stirring mechanism. The stirring mechanism includes a rotating shaft 14, a mixing tube 8 and a driving mechanism for driving the rotating shaft 14 to rotate. The rotating shaft 14 is installed in rotation. In the mid...

Embodiment 2

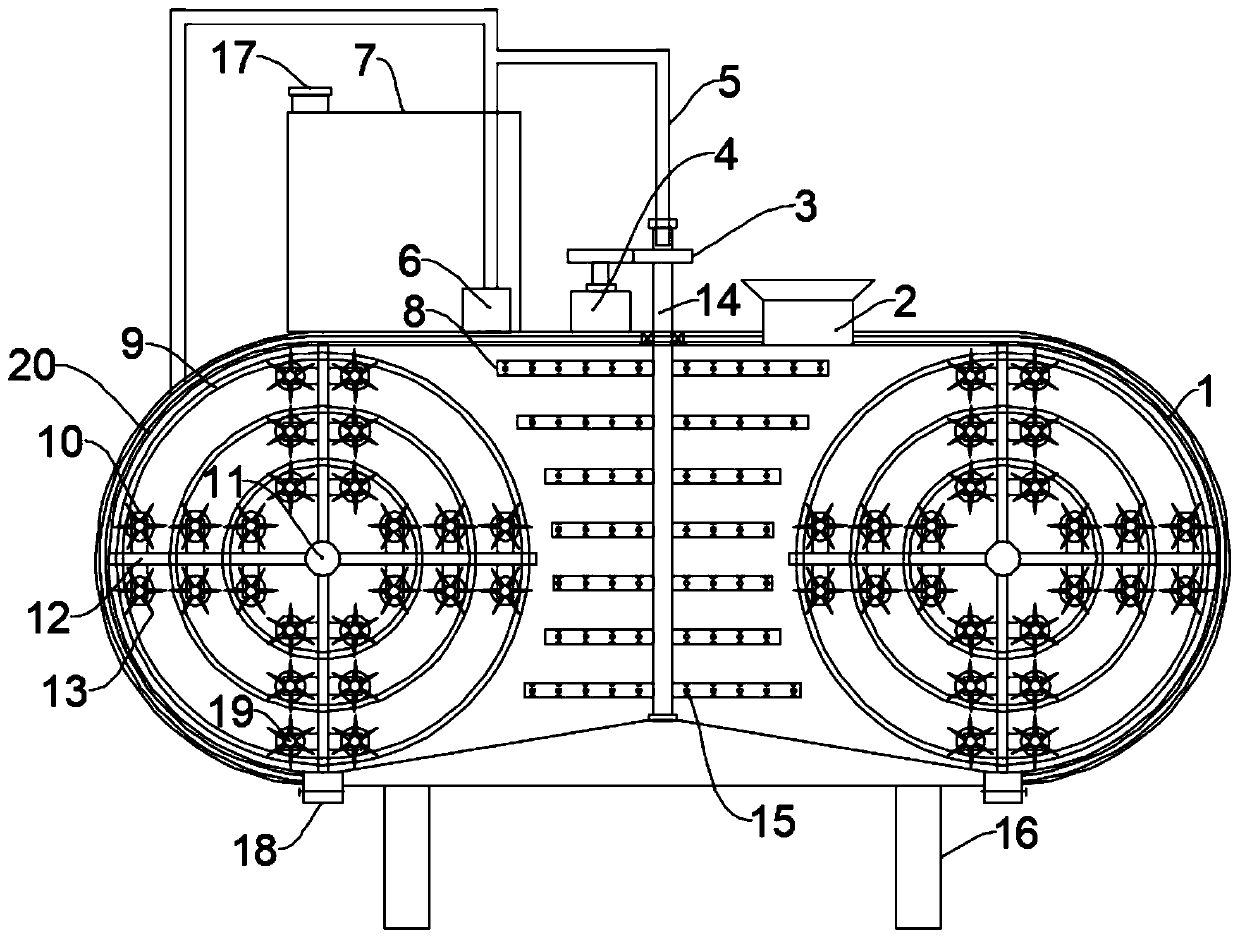

[0027] see image 3 The difference between this embodiment of the present invention and Embodiment 1 is that a liquid channel 20 is provided on the upper wall of the box body 1, and a channel communicating with the liquid channel 20 is evenly opened on the upper inner wall of the box body 1. A protective net is installed in the through hole, and the other liquid outlet pipe of the liquid supply pipeline 5 communicates with the liquid channel 20. When the soil is mixed and scattered, the repair liquid is further mixed with the soil to improve the repair efficiency.

[0028]The working principle of the present invention is: when working, the soil is added into the box body 1 from the feed hopper 2, the driving mechanism is started to drive the rotating shaft 14 to rotate, and the rotating shaft 14 drives the mixing tube 8 to rotate, and the mixing tube 8 can crush the falling part of the soil , the soil falls to the bottom of the inner cavity of the box body 1, slides to both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com