A stretch-bending straightening process for stainless steel cold-rolled strip

A technology of stretch bending straightening and stainless steel, which is applied in the field of metal material production and processing, can solve the problems of electronic products or mobile phones and other internal components that cannot be assembled normally, affect the performance and overall service life, and achieve the elimination of plate defects and improve The effect of improving the quality of the plate shape and improving the performance of deep processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

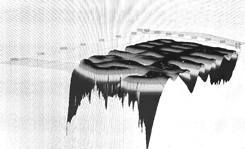

Image

Examples

specific Embodiment 2

[0025] A kind of stretch-bending straightening process of stainless steel cold-rolled strip realizes steps as follows:

[0026] Fix the stainless steel cold-rolled strip coil with a thickness of 0.2mm and a hardness of 280HV to the uncoiler, and use an automatic traction device to install it sequentially through the brake S-roller group, bending equipment, and traction S-roller group, and then fix the strip head to the winder ;Set uncoiler tension to 45N / mm 2 , set the tension of the brake S-roller group to 140N / mm 2 , the entrance of the bending unit is set to -1.6mm, the elongation of the strip is set to 0.3%, and the tension of the winder is set to 45N / mm 2 , the processing speed is set to 70m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com