Low-noise pneumatic tire

A pneumatic tire, low-noise technology, applied in pneumatic tires, tire parts, vehicle parts, etc., can solve the problems of single frequency, reduce driving stability, improve driving danger, etc. The effect of energy interval, significant noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

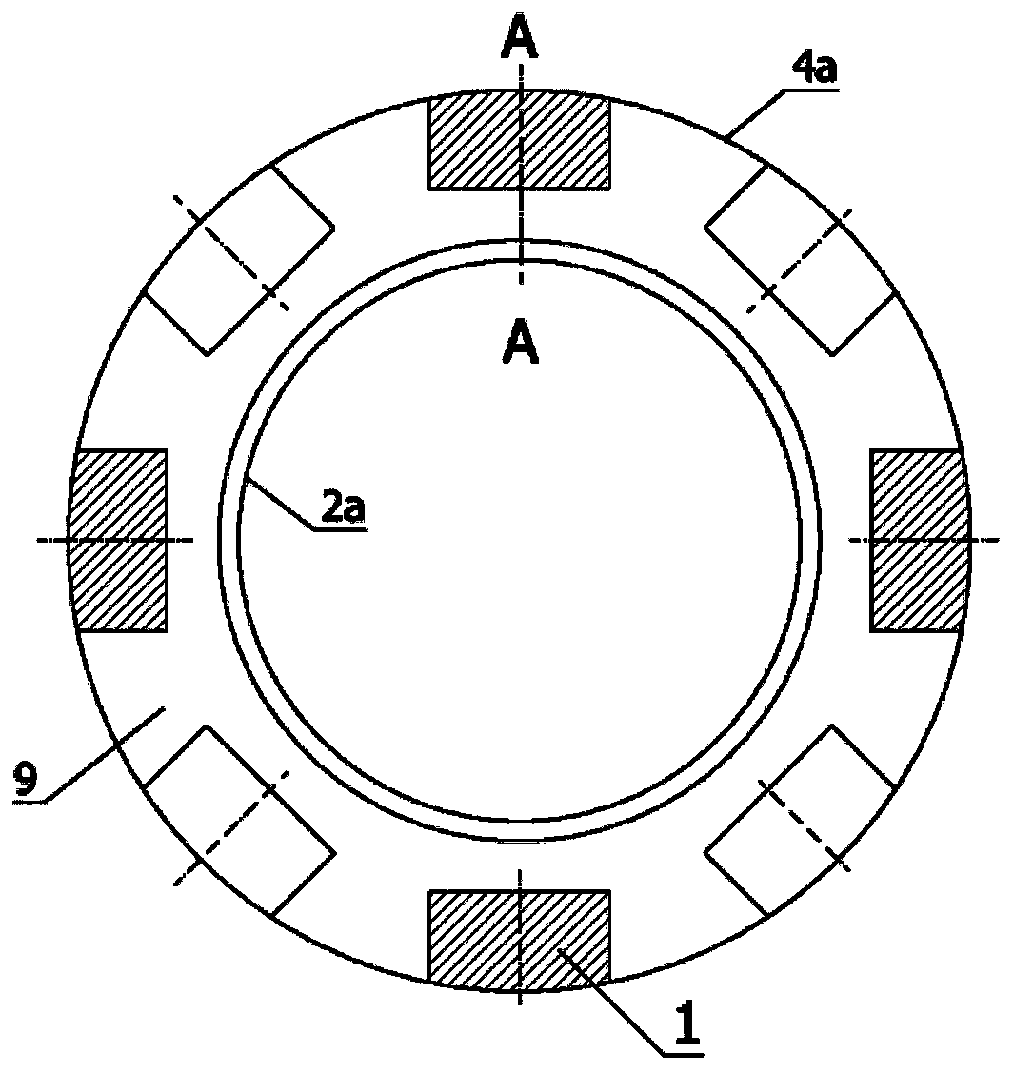

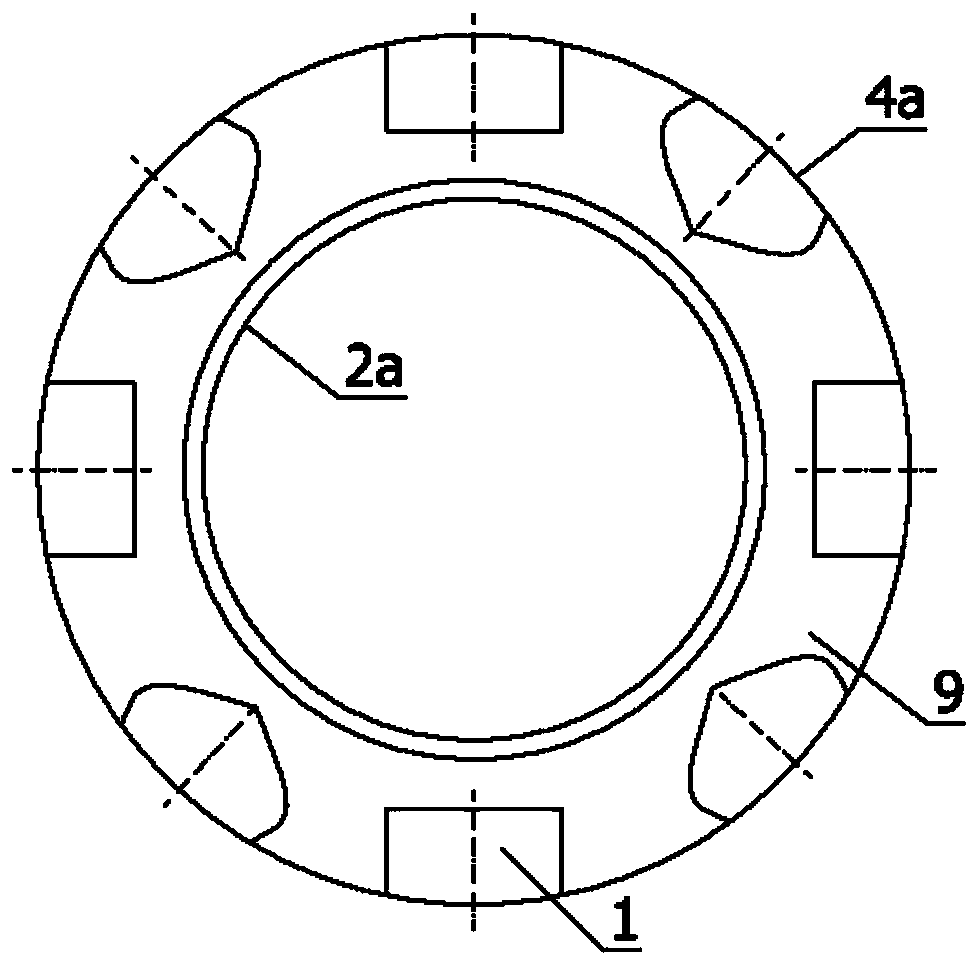

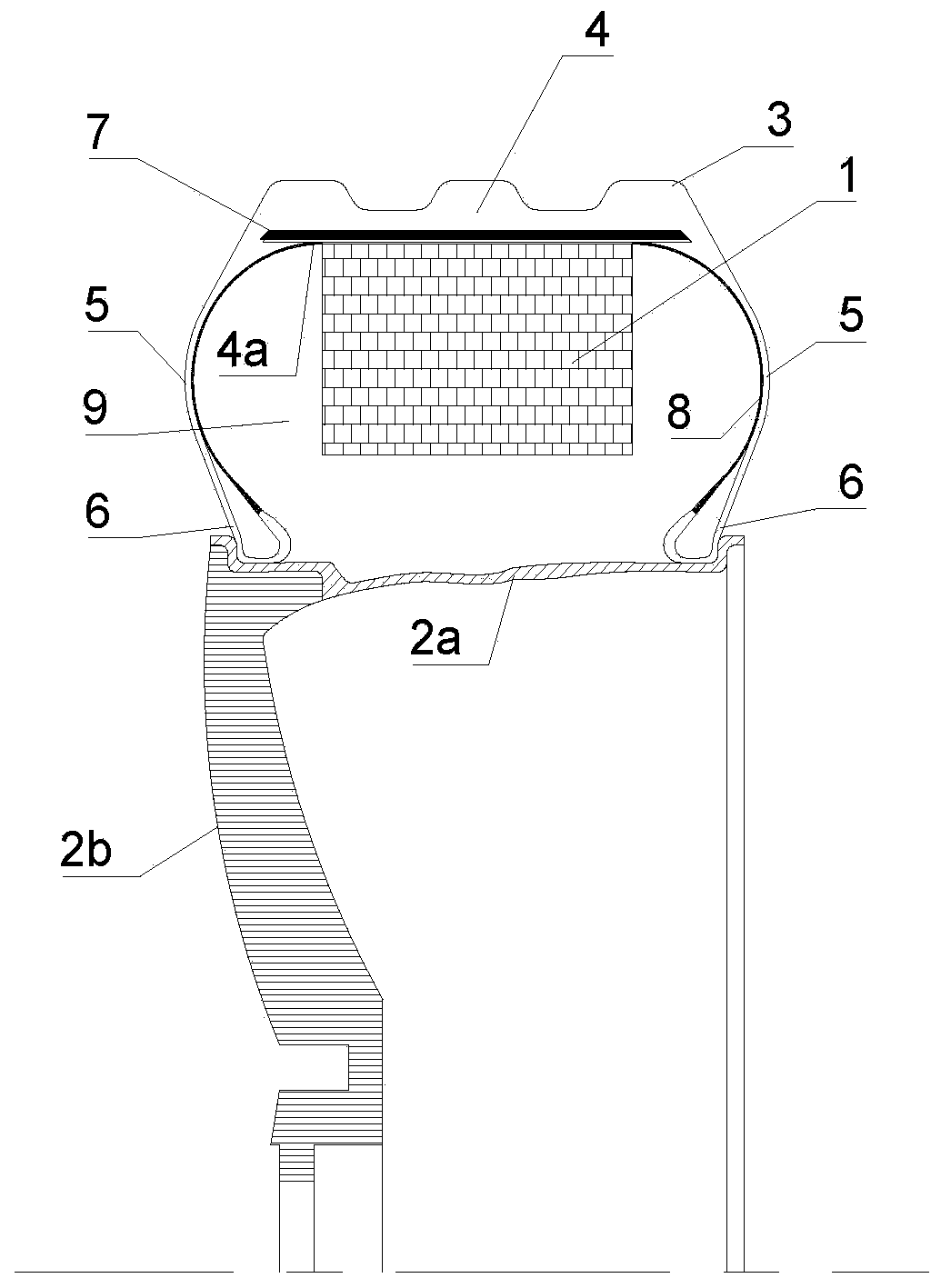

[0039] see image 3 , the pneumatic tire in this embodiment refers to the pneumatic tire 3 formed with the annular tire cavity 9 jointly by the tread inner surface 4a of the tire and the rim 2a, and the pneumatic tire 3 is installed on the rim 2a and supported by the spokes 2b; the pneumatic tire 3 includes: the tread portion 4, the bead portion 6 on the left and right sides, the sidewall portion 5 on the left and right sides connecting the tread portion 4 and the bead portion 6; between the left and right bead portions 6 A carcass 7 extends inside the tire, a belt 8 is provided on the outer peripheral side of the carcass of the tread portion 4, and the pneumatic tire 3 is mounted on a wheel so that the cavity of the pneumatic tire 3 is sealed via the rim 2a.

[0040] Such as image 3As shown, in the present embodiment, the low-noise pneumatic tire is provided with a sound absorbing body 1 in the annular tire cavity 9 jointly formed by the tread inner surface 4a and the rim 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com