An elevator guide rail crawling robot

A crawling robot and elevator guide rail technology, which is applied in the field of elevator rail transportation devices and elevator guide rail crawling robots, can solve the problems of limited applicable scenarios, single function, complex robot structure, etc., and achieve the effect of wide application range and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

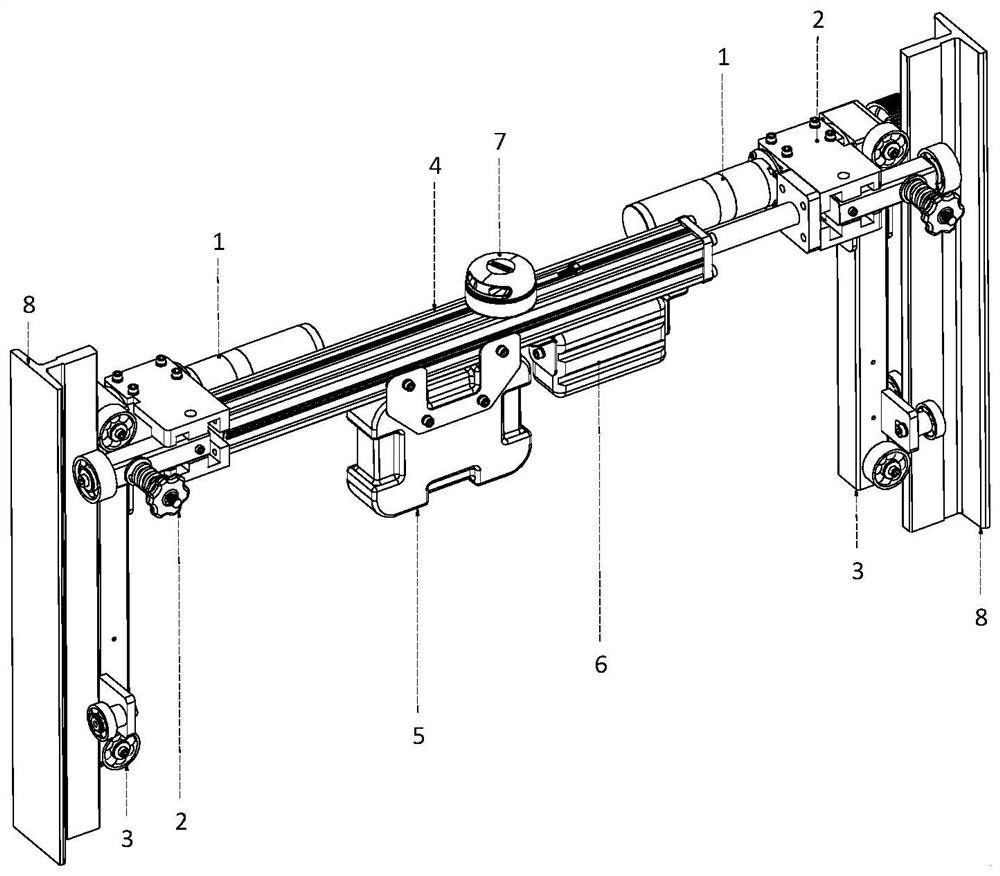

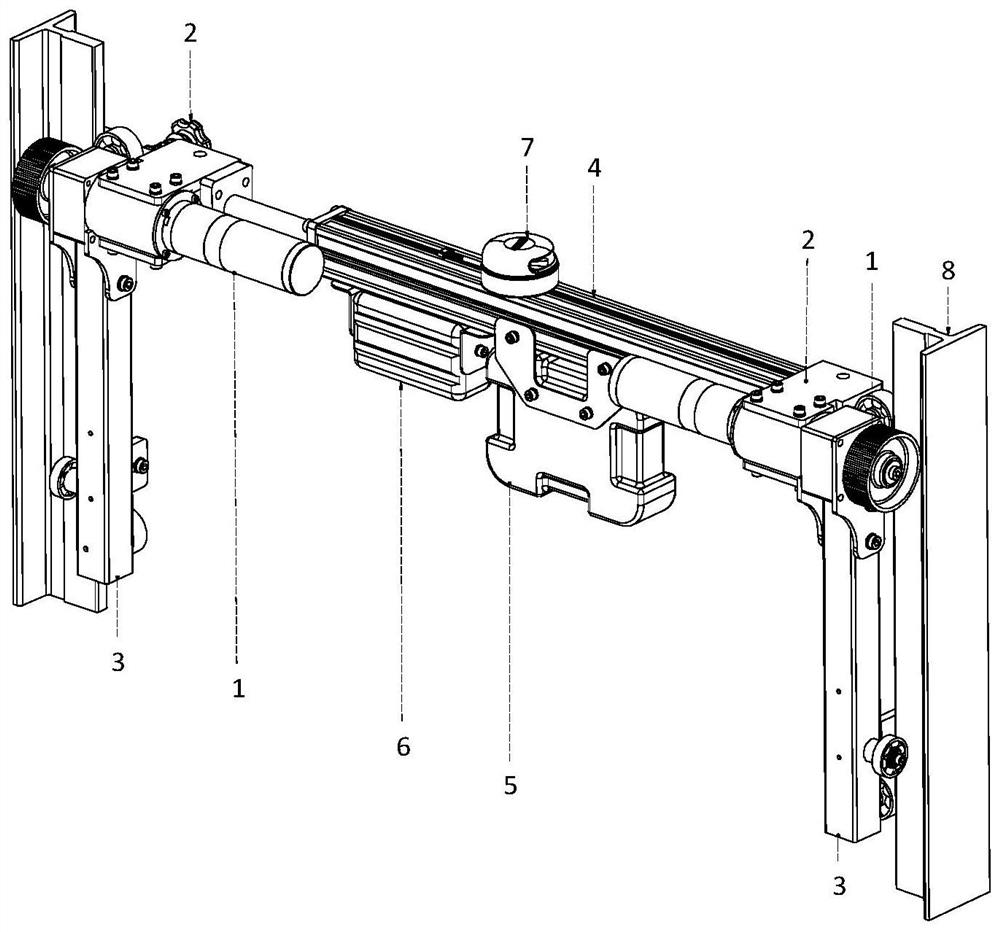

[0044] like Figure 1-2 As shown: this embodiment provides an elevator guide rail robot, including a slidable frame 4, a traction unit 1, a gripper unit 2, a stabilizing arm unit 3, a detection unit, a control module and a power supply module; the elevator guide rail robot is in the form of "Long" type structure, the traction unit 1, the gripper unit 2, and the stabilizing arm unit 3 connected by the slidable frame 4 each have a pair and are symmetrically arranged, and together with the slidable frame, they form the climbing mechanism of the robot; the control module And the power supply module controls the climbing mechanism of the robot to move up and down on the elevator guide rail. The detection unit detects multiple safety parameters of the guide rail and the route status of the robot on the guide rail in real time, making the crawling transportation of the elevator track safer and more efficient.

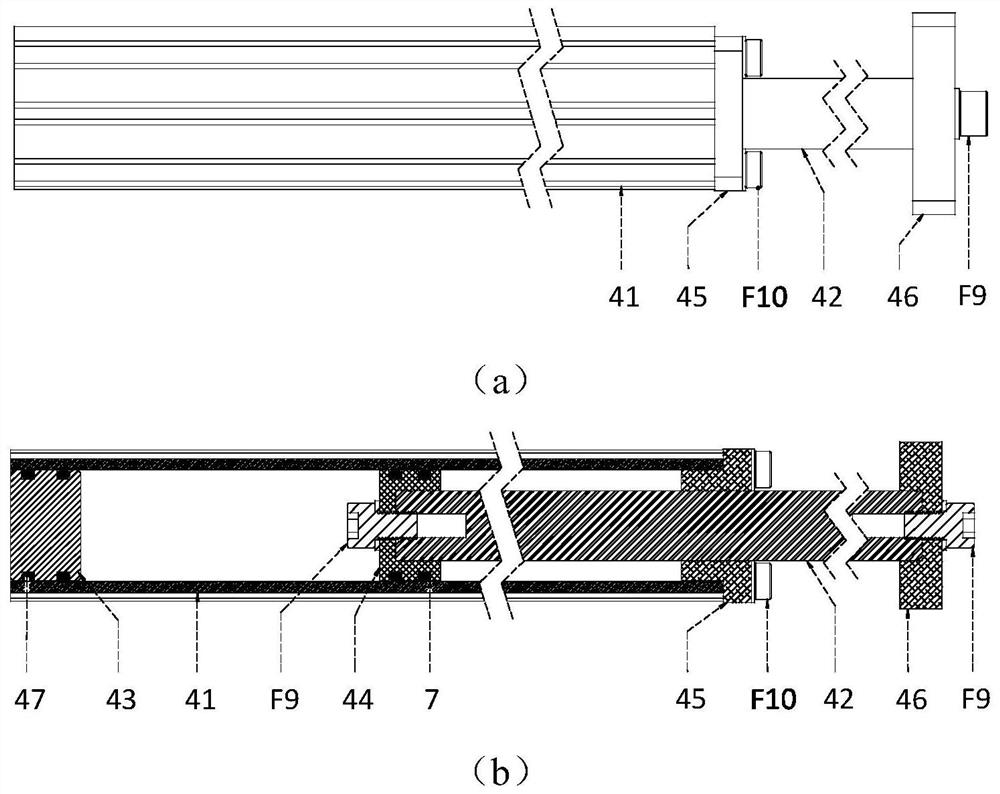

[0045] In this example, if Figure 3-4 , the slidable frame 4 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com