Lifting device for heavy machinery

A lifting device and heavy machinery technology, applied in the direction of lifting devices, lifting frames, etc., can solve problems such as instability, lower lifting efficiency, equipment shaking, etc., to improve convenience and safety assurance, improve work safety, and facilitate maintenance The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

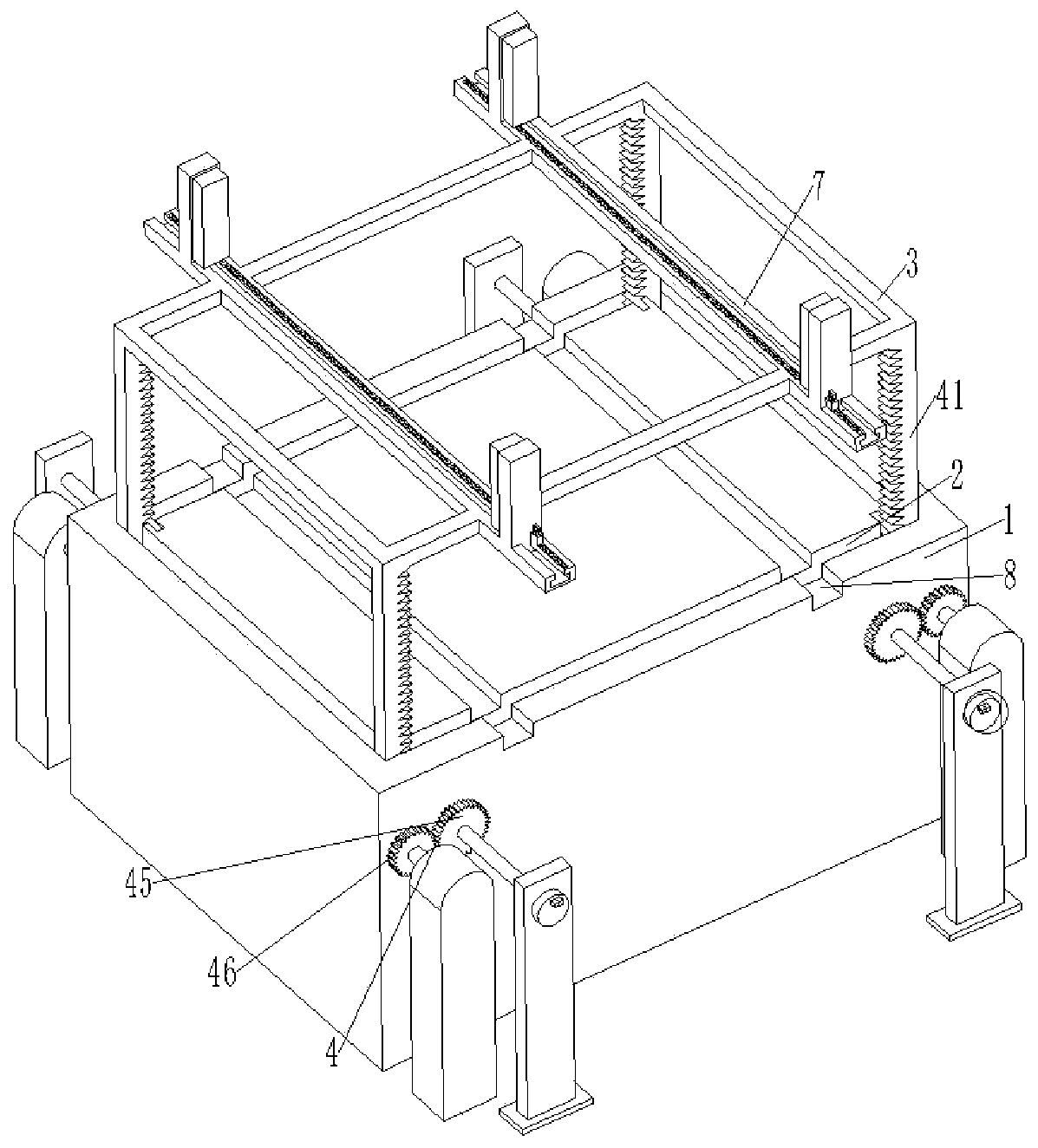

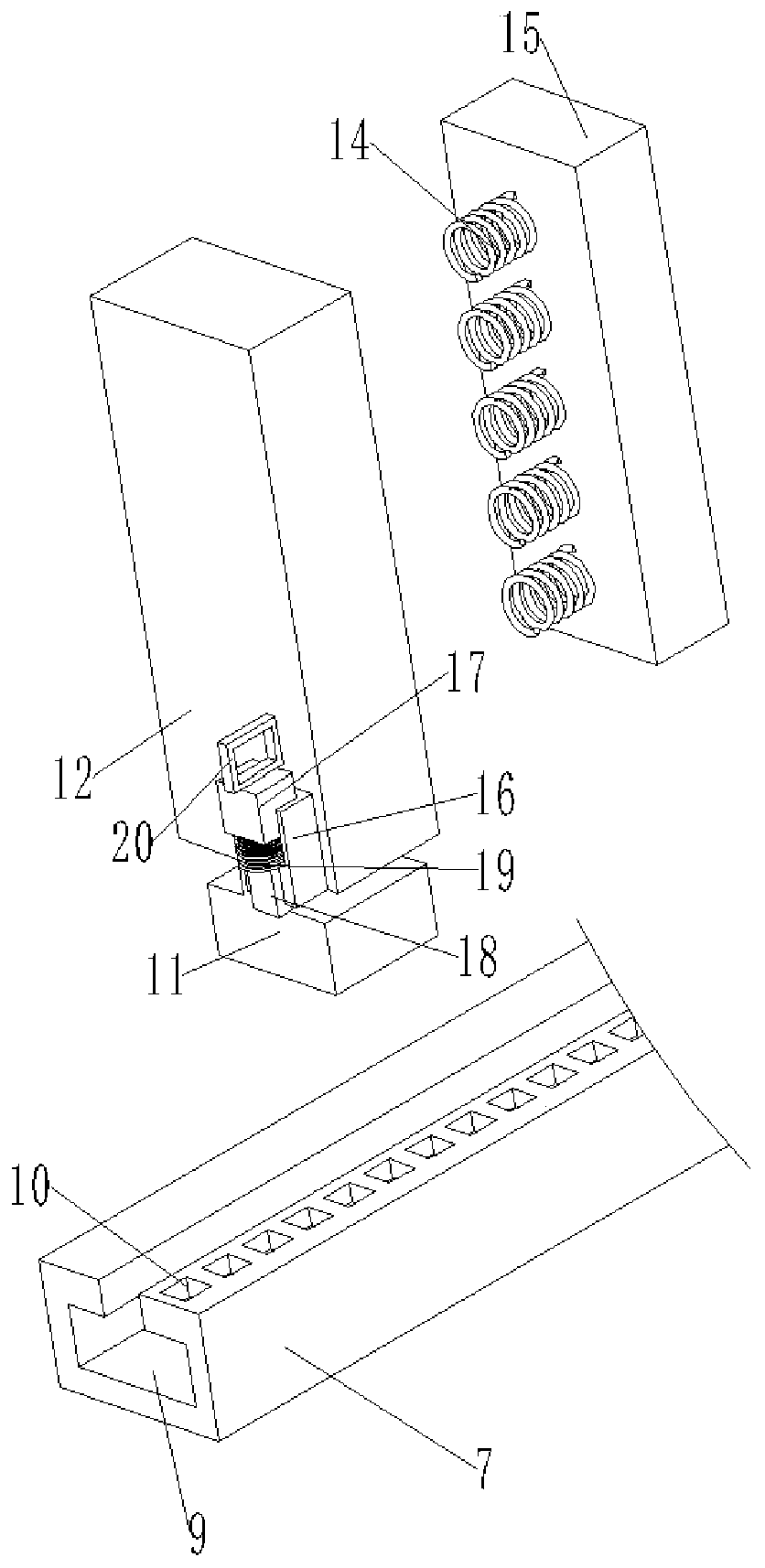

[0029] See Figure 1 to Figure 8 , The present invention provides a lifting device for heavy machinery, including a main body 1, a transmission device 4 and a fixing device 6. The main body 1 is provided with a placing groove 2 and a square groove 8 and a supporting frame 3 is clamped in the placing groove 2, and a transmission device 4 is connected to the supporting frame 3. The support frame 3 is symmetrically provided with support rods 7, the support rod 7 is provided with convex sliding grooves 9 therethrough, and the upper surface of the support rod 7 is equidistantly provided with fixed square grooves 10. A convex sliding block 11 is slidably connected to the convex sliding groove 9, and the convex sliding block 11 is disposed at the bottom end of the first pressing plate 12. One side of the first pressing plate 12 is provided with an pressing groove 13, the pressing groove 13 is equidistantly provided with a connecting spring 14, and the other end of the connecting spri...

Embodiment 2

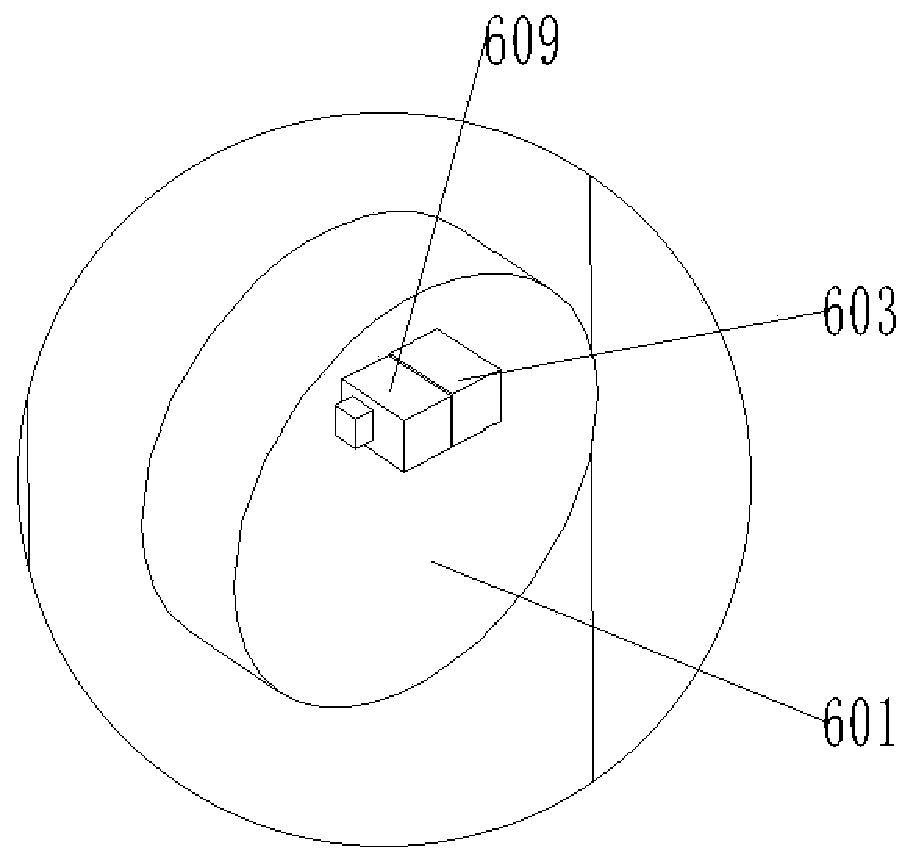

[0032] In a preferred embodiment, the fixing device 6 includes a disc 601, a fixing circular groove 602, a first square insert 603, a circular insert 604, a first return spring 605, a groove 606, an extrusion spring 607, The clamping block 608, the convex block 609, the second square plug block 610, the third-shaped plug block 611, the second return spring 612, the disc 601 is arranged at one end of the second transmission shaft 47, and the fixed circular grooves 602 are arranged equidistantly in the fixed On the board 5, the disc 601 is provided with a first square slot, one end of the first square slot is provided with a circular slot, and a first square plug 603 is inserted into the first square slot , A circular plug 604 is inserted into the circular slot, the circular plug 604 is arranged at one end of the first square plug 603, and the first square plug 603 is arranged on the same end as the circular plug 604 The other ends of the first return spring 605 and the first ret...

Embodiment 3

[0034] In a preferred embodiment, the cross-sectional shape of the fifth square insert 18 is the same as the cross-sectional shape of the notch of the fixed square groove 10, and the length and width of the two cross-sectional shapes are the same.

[0035] In a preferred embodiment, the thickness of the first gear 43 is equal to the width of the rack 41.

[0036] In a preferred embodiment, the tooth profile angle and modulus of the third gear 46 and the second gear 45 are the same, and the tooth profile angle and modulus of the first gear 43 and the rack 41 are also the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com