Flexible ultrathin material treatment system

A processing system and ultra-thin technology, applied in the field of flexible ultra-thin material processing systems, can solve the problems of low automation and achieve high automation and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below.

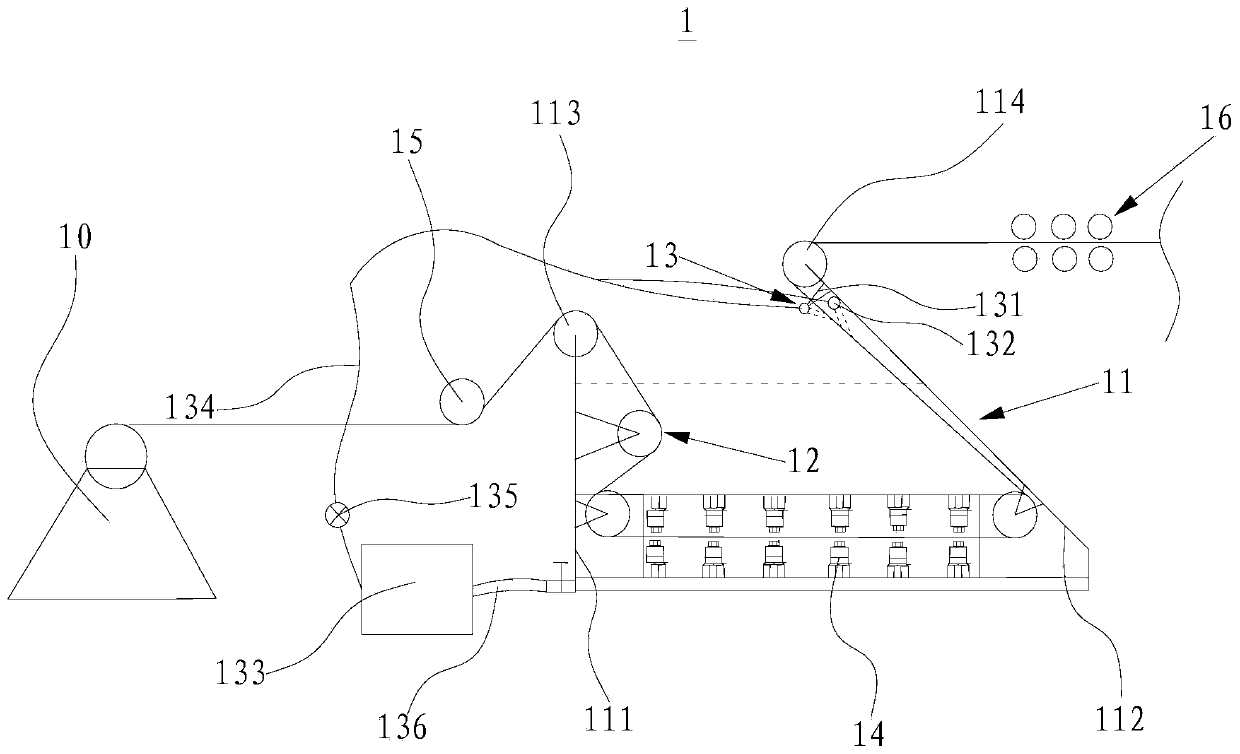

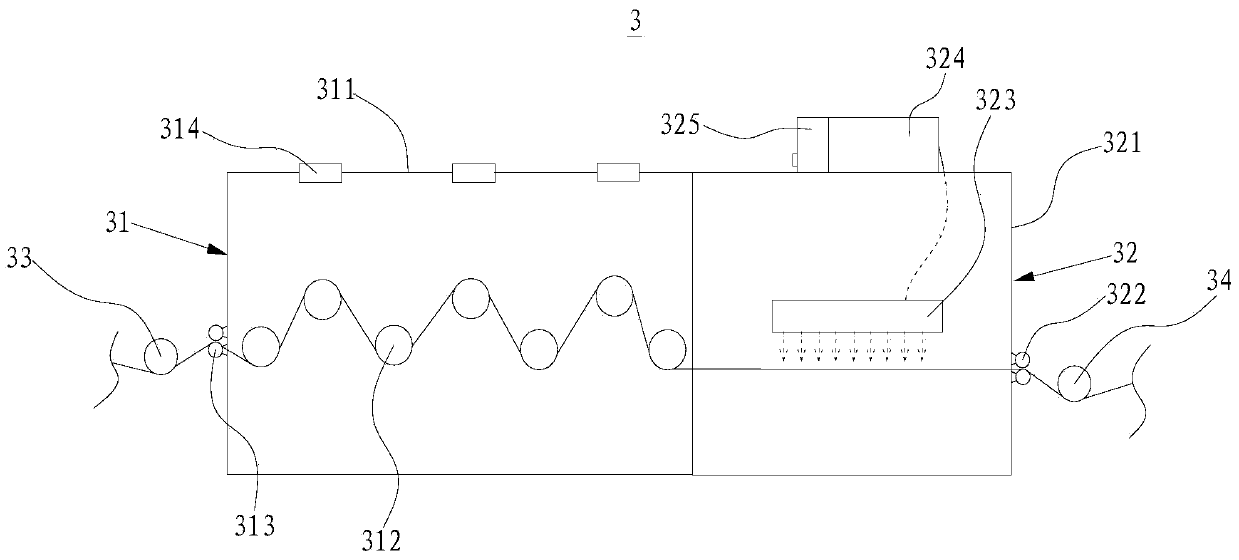

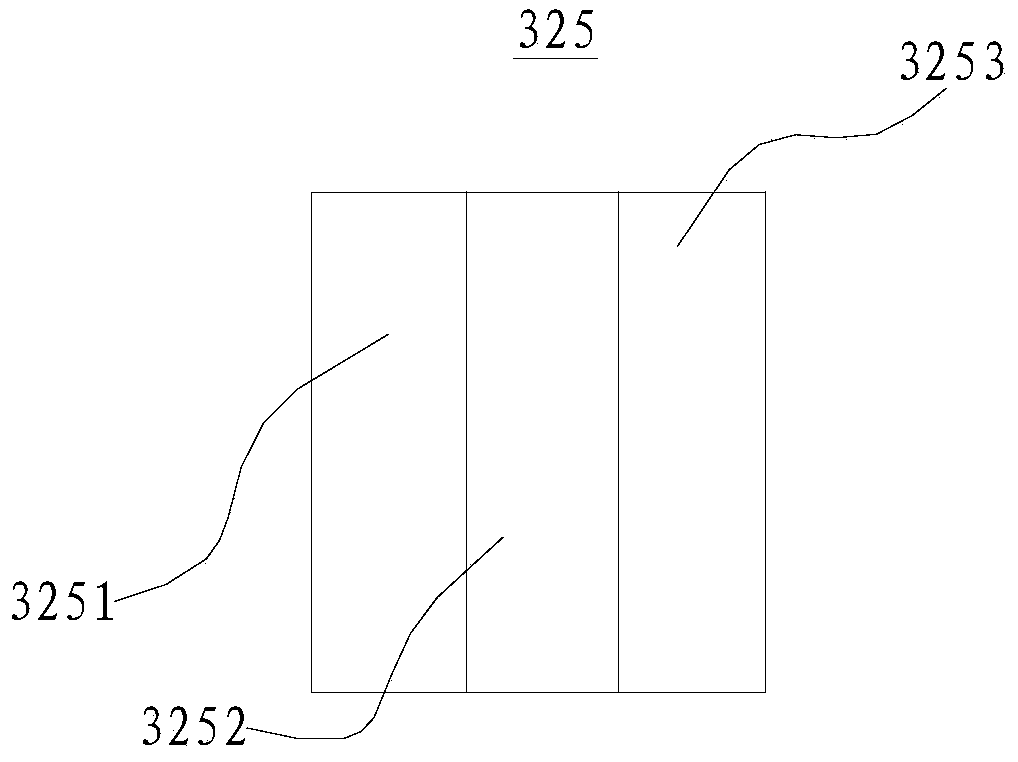

[0025] Such as Figure 1 to Figure 5 The flexible ultra-thin material processing system shown mainly includes a matching cleaning component 1, a drying component 3, and a cutting device 2, etc.

[0026] Wherein, the cleaning assembly 1 includes an unwinding rack 10 (the unwinding rack 10 is used to place the flexible ultra-thin material roll to be cleaned, and the existing one can be used; you can refer to the Chinese utility model patent with application number 201921759256.5), The cleaning tank 11 ( figure 1 Among them, the cleaning tank 11 is located on the right side of the unwinding frame 10), the cloth guide roller group 12 installed in the cleaning tank 11, and the ultrasonic mechanism installed in the cleaning tank 11 or its bottom; the cleaning assembly 1 also includes a The water pressure mechanism 16 on the side of the cleaning tank 11, the water pressure mechanism 16 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com