Laundry dryer with acceleration sensor and method for its operation

An acceleration sensor and laundry technology, which is applied to washing machines with containers, washing devices, other washing machines, etc., can solve the problems of inaccurate sensor signals, inability to design and layout flexibly, large structure space of sensors, etc., to improve the measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

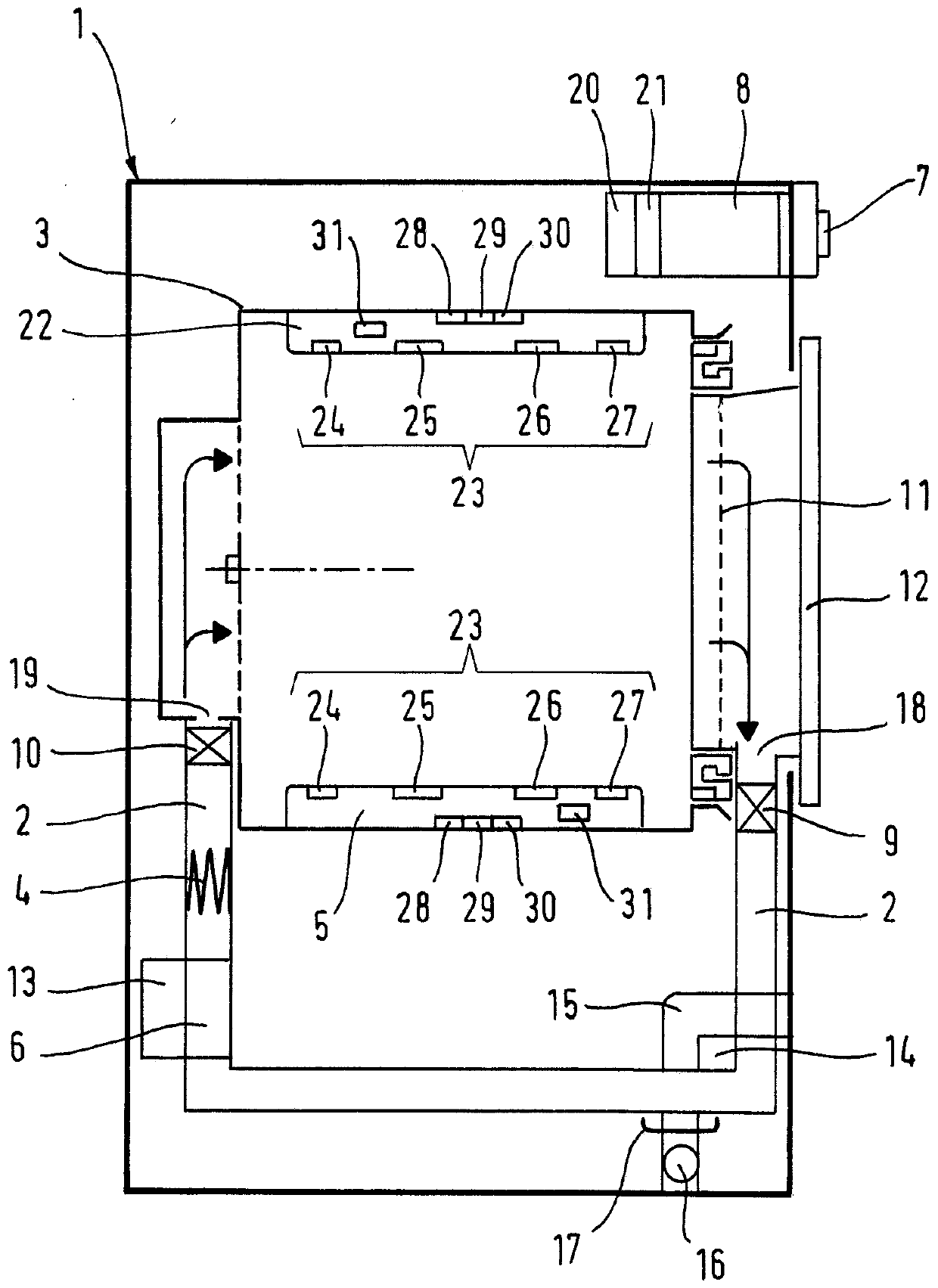

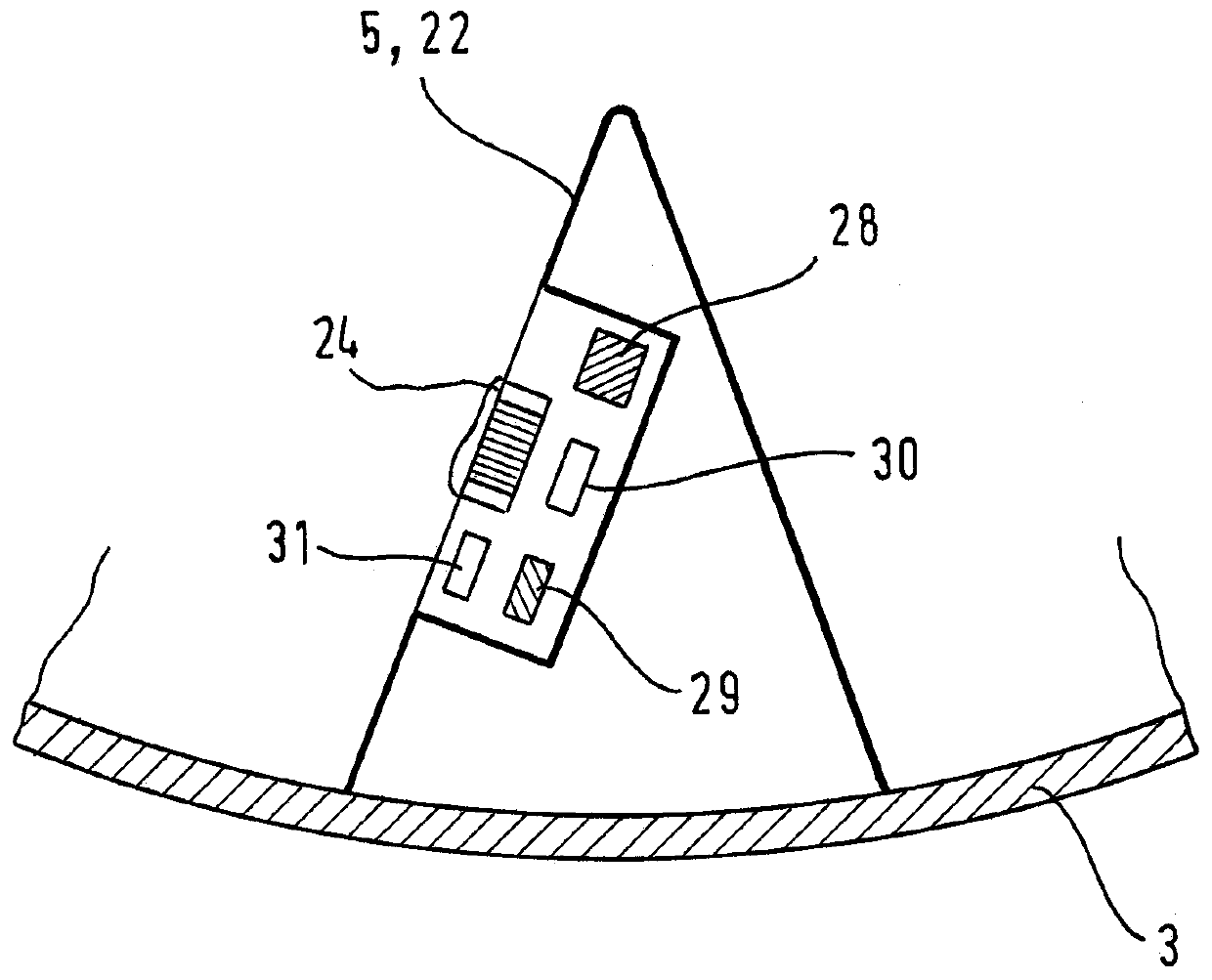

[0079] figure 1 A vertical section through a laundry dryer according to the invention is shown, which is designed as a condensation dryer, wherein the arrows indicate the flow direction of the process air. Other implementations are contemplated.

[0080] figure 1 The laundry dryer 1 shown in has a drum 3 rotatable around a horizontal axis for receiving laundry, not shown here, to be dried, for driving the laundry in motion during the rotation of the drum A piece 5, 22 is mounted inside said drum. Process air is guided through the drum 3 in the process air line 2 by means of a process air blower 6 via an air-to-air heat exchanger 14 and an electric heater 4 . In this case, the air heated by the electric heater 4 is guided into the drum 3 via the drum inlet 19 from the rear, ie from the side of the drum 3 opposite the door 12 , through the perforated bottom of the drum 3 .

[0081] After exiting the drum 3 , the moisture-laden process air flows through the filling opening of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com