Diaphragm and diaphragm coupling

A diaphragm coupling and diaphragm technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problem of affecting the operation of equipment, factory production and processing, unable to limit the amount of axial movement, diaphragm fatigue fracture, etc. problems, to achieve the effect of improving transmission stability, enhancing structural strength and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

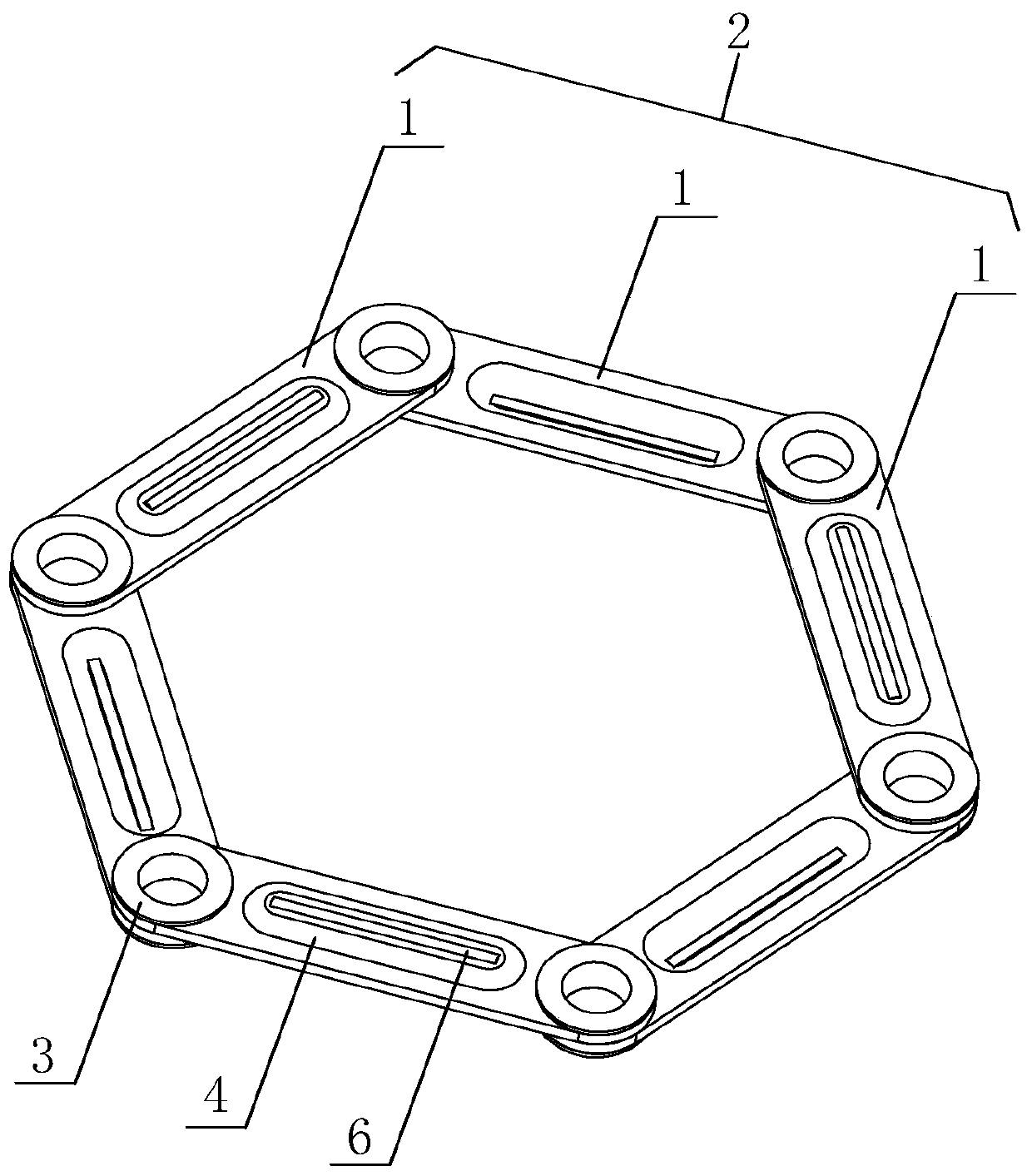

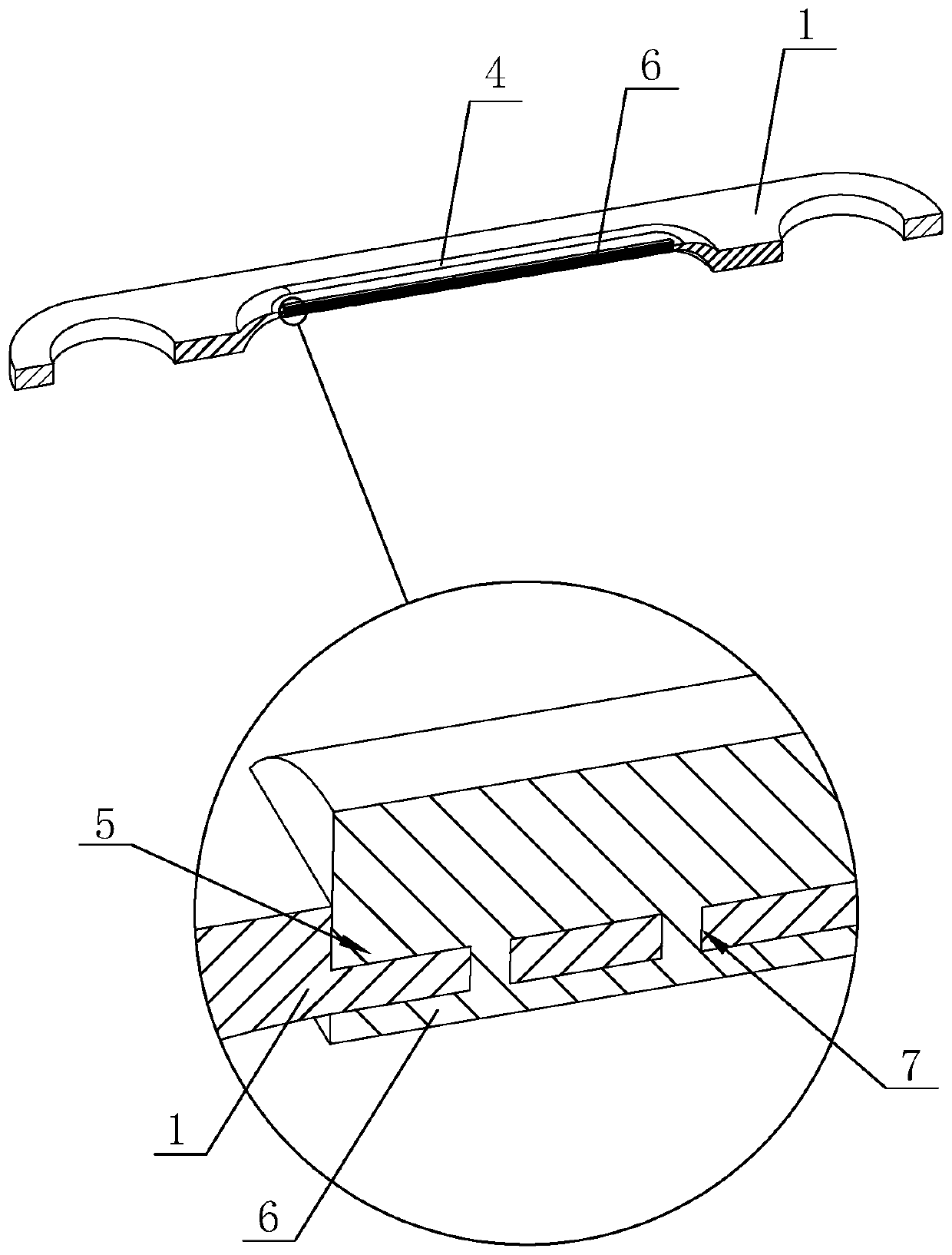

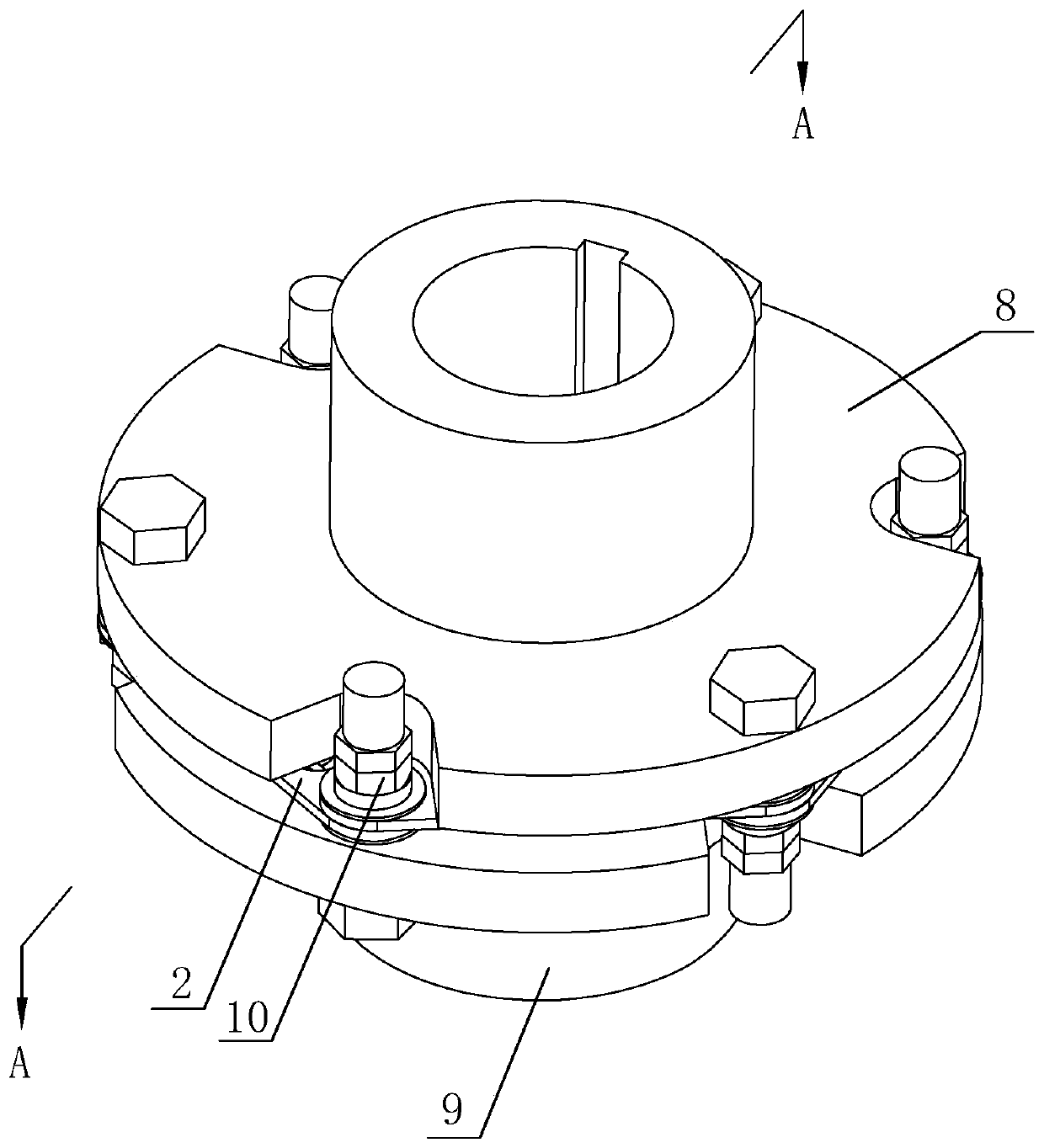

[0034] refer to figure 1 with figure 2 , is a diaphragm disclosed by the present invention, including six laminated diaphragm rods 1, and the six laminated diaphragm rods 1 are hinged end-to-end to form a diaphragm ring 2, and adjacent laminated diaphragm rods 1 are arranged alternately. A hinge ring 3 is installed at the hinge of the laminated diaphragm rod 1, and a stamping rib 4 is arranged on the laminated diaphragm rod 1 along its length direction, and the stamping rib 4 is formed by stamping on one side of the laminated diaphragm rod 1 , the raised portion of the stamped rib 4 is located between the adjacent laminated diaphragm rods 1 , and the height of the raised side of the stamped rib 4 is greater than the height of the hinge ring 3 . By stamping and processing the stamping ribs 4 on the laminated diaphragm rod 1, on the one hand, the structural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com