Storage tank bottom plate corrosion damage experiment testing device

A storage tank bottom plate and testing device technology, which is applied to measuring devices, weather resistance/light resistance/corrosion resistance, material analysis using acoustic wave emission technology, etc., can solve the problem of incomplete evaluation results, small detection coverage, and ultrasonic guided wave technology Low monitoring efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

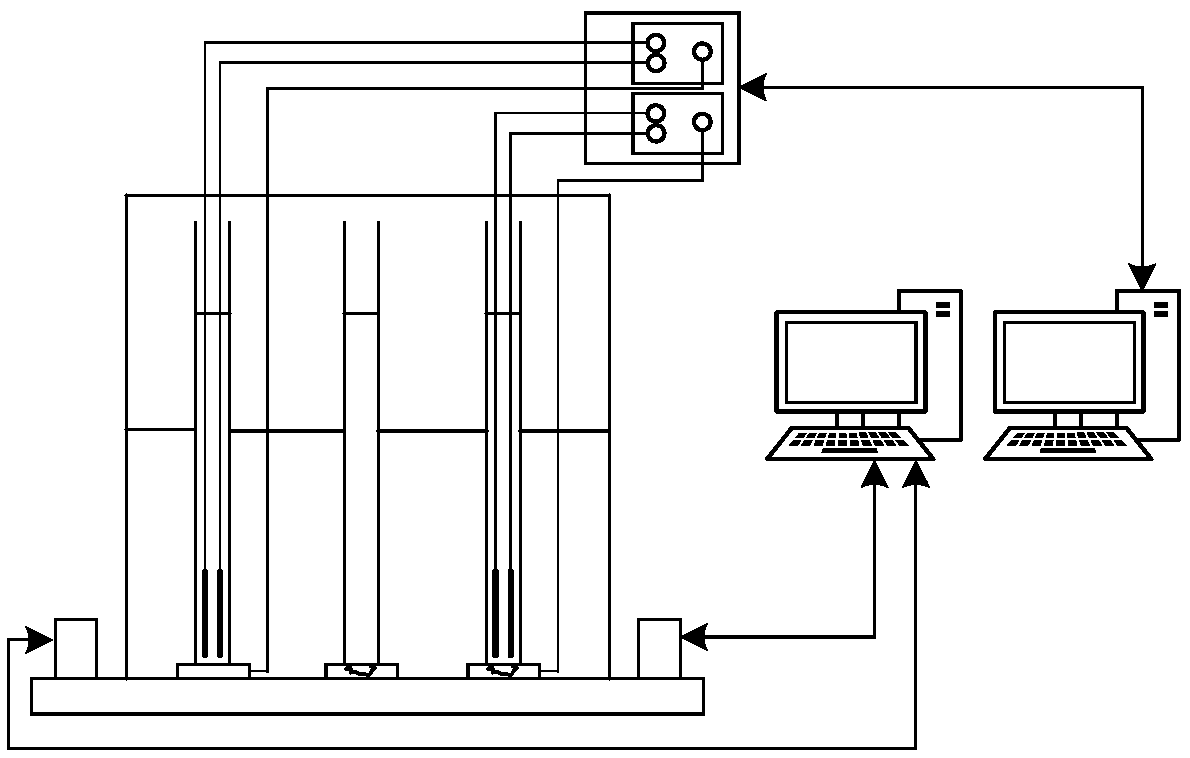

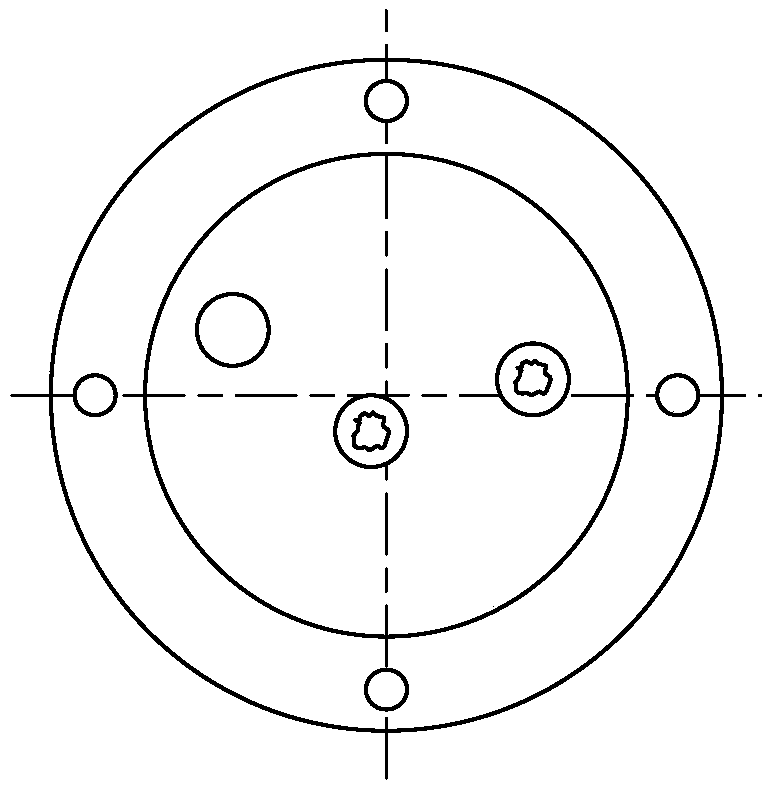

[0020] Such as figure 1 with figure 2 As shown, a storage tank floor corrosion damage experimental testing device includes a simulated storage tank, first to third simulated corrosion source specimens, an active and passive acoustic fusion detection system, an electrochemical workstation and an electrochemical control system. An acoustic wave sensor is installed on the edge plate of the bottom of the tank, and the acoustic wave sensor is electrically connected to the active and passive acoustic fusion detection system; the bottom plate of the simulated storage tank is covered with an anti-corrosion coating except for the reserved metal luster circle area, and each metal luster circle There is a simulated corrosion source test piece closely coupled in the area. The simulated storage tank is filled with pure aqueous solutio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap