Test mold for corrosion of reinforced concrete and stress monitoring method for corrosion process

A technology for reinforced concrete and testing molds, applied in the direction of measuring force, measuring devices, and material analysis through optical means, can solve the problems of heavy crack collection workload, difficult to capture micro-cracks, and large manpower and material resources, and achieve the measurement environment. Low vibration isolation requirements, short test period, and convenient erection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

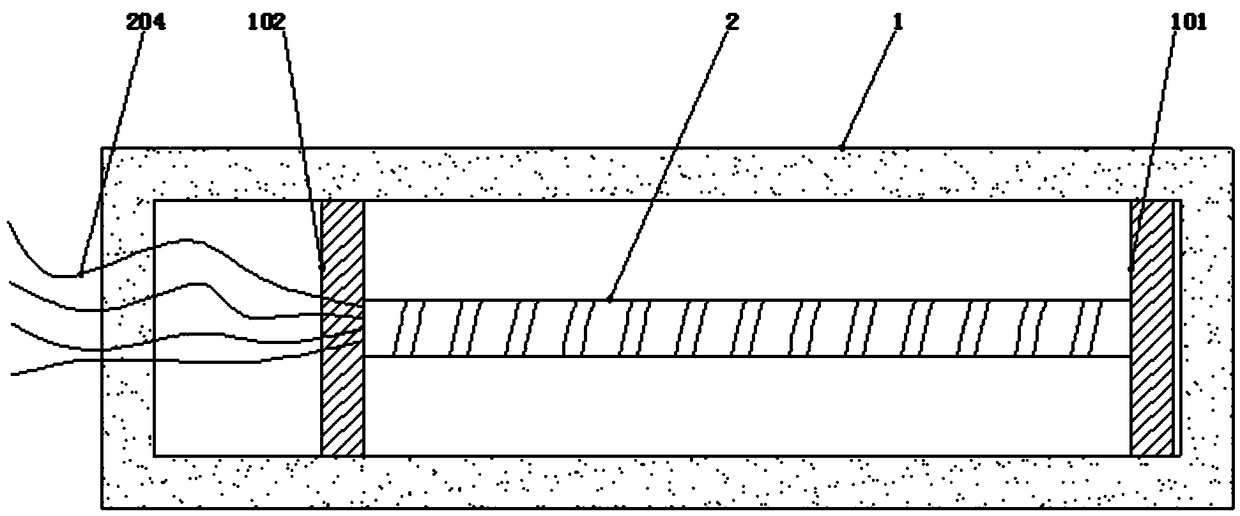

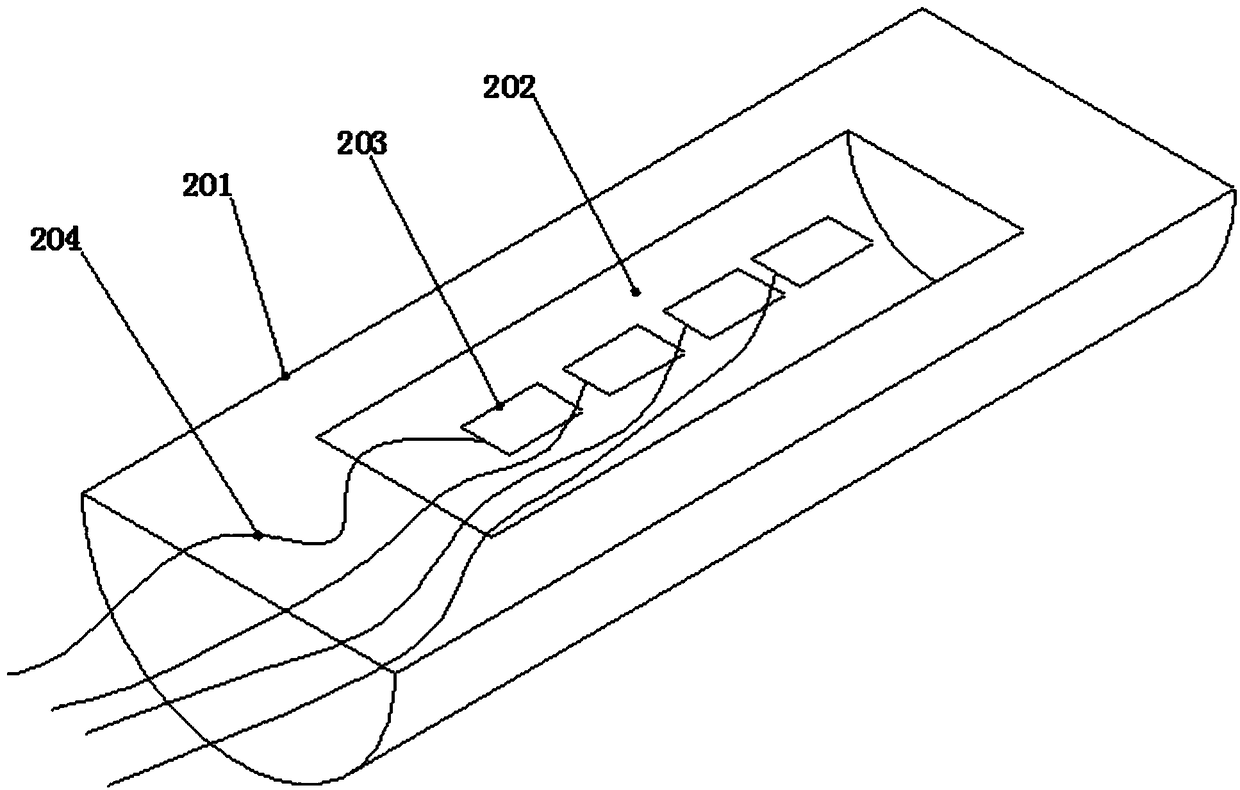

[0048] Such as Figure 1-7 Shown, the present invention provides a kind of test mold of reinforced concrete corrosion and the stress monitoring method of corrosion process, and test mold comprises:

[0049] Die groove 1, described mold groove 1 is cuboid, and described mold groove 1 upper opening, interior is provided with cavity;

[0050] The baffle, the baffle is arranged in the cavity of the mold groove 1, and the baffle includes a first baffle 102 and a second baffle 101; the first baffle 102 is fixedly arranged in the mold groove 1 One end of the mold groove 1, the second baffle plate 101 is fixedly arranged at the other end of the mold groove 1, and a space is reserved between the first baffle plate 102 and the inner side wall of one end of the mold groove 1, and the second baffle plate 101 is close to the mold groove 1. The inner wall of the other end of the mold groove 1;

[0051] Steel bar test piece 2, the steel bar test piece 2 is located in the cavity of the mold...

Embodiment 2

[0073] Such as Figure 8-9 As shown, in this embodiment, in order to accelerate the corrosion rate of the reinforced concrete specimen, the solution and the stainless steel sheet are set in the reinforced concrete specimen, and the specific method is as follows:

[0074] Step 1, first place a conductive stainless steel sheet in the groove of the specimen formed during the fabrication of the reinforced concrete specimen;

[0075] Step 2, adding a solution that can accelerate the corrosion rate of the reinforced concrete specimen in the groove of the specimen above the stainless steel sheet;

[0076] Step 3, connect the cathode of the power supply on the stainless steel sheet, and connect the anode of the power supply on the surface of the reinforced concrete specimen, thus forming a closed loop of electric acceleration effect.

[0077] The added solution accelerates the corrosion rate of reinforced concrete. In addition, adding an external power supply to the stainless steel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com