Experimental testing equipment for mixed gas adsorption capacity of coal rock/shale

A technology of mixed gas and testing equipment, which is applied in the direction of measuring equipment, permeability/surface area analysis, suspension and porous material analysis, etc., to achieve the effects of convenient production, overcoming gas stratification, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

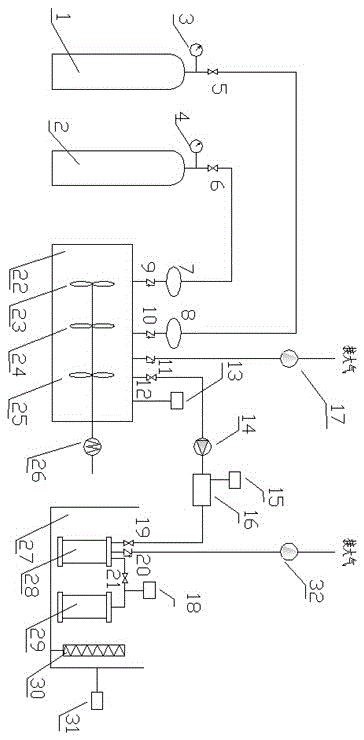

[0016] Such as figure 1 As shown, an experimental test device for the adsorption capacity of mixed gas in coal rock / shale, the first gas storage bottle 1 and the second gas storage bottle 2 are respectively communicated with the gas mixing container 22, and the gas mixing container 22 passes through the gas storage box 16 communicates with the reference tank 28 and the sample tank 29 in sequence, and the first electromagnetic valve 5, the first electromagnetic flowmeter 7 and the second electromagnetic valve 6 are arranged between the first gas storage bottle 1 and the second gas storage bottle 2 and the gas mixing container 22 , the second electromagnetic flowmeter 8 . The first gas storage bottle 1 and the second gas storage bottle 2 are respectively provided with a first pressure gauge 3 and a second pressure gauge 4 , and a rotating vane is installed in the gas mixing container 22 , which is driven by a low-frequency motor 26 . The gas mixing container 22 communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com