A kind of cabinet door automatic opening and closing mechanism and express cabinet containing it

An automatic switch and cabinet door technology, which is applied to coin-free or similar appliances, coin-operated equipment with instrument control, and coin-operated equipment for distributing discrete items, etc. The rotating connecting shaft of the cabinet door is damaged and prone to swing up and down, so as to ensure the safety of use, facilitate centralized maintenance and improve the safety of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

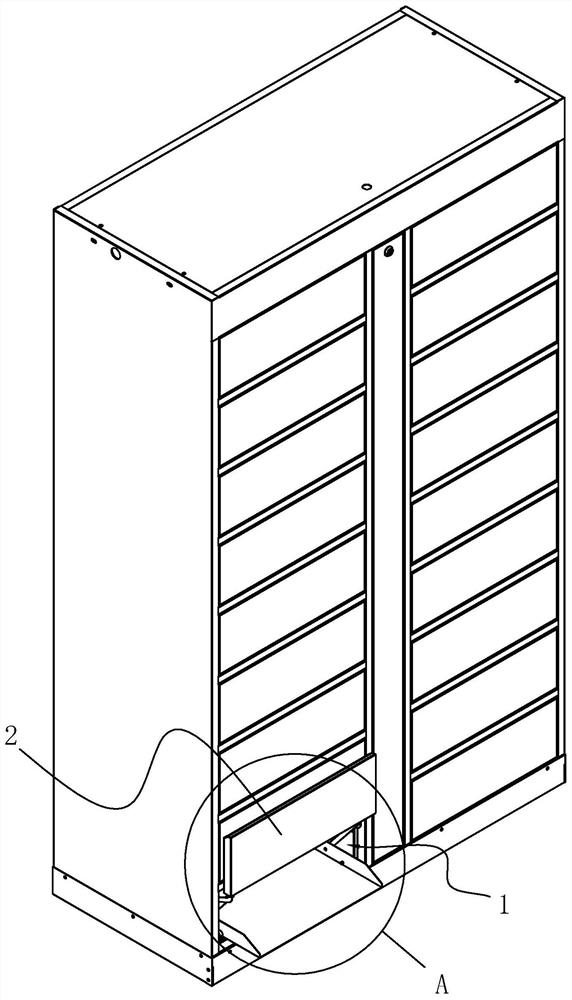

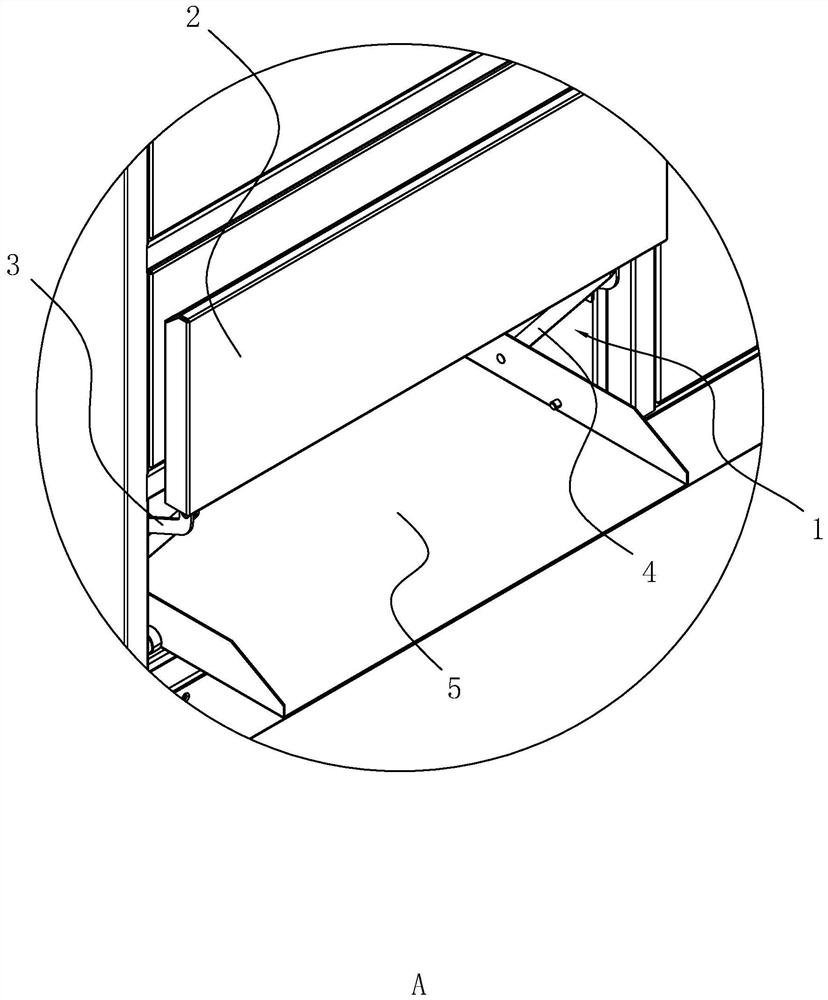

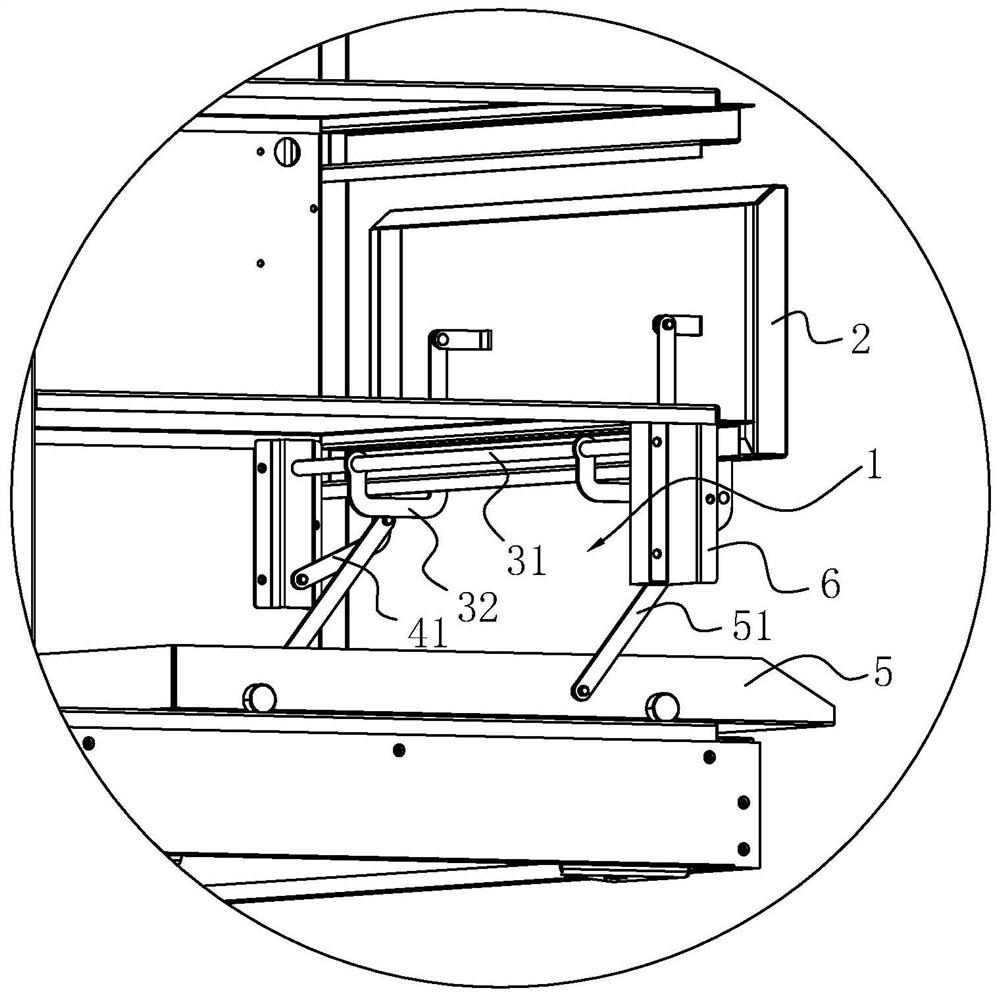

[0051] Example 1: Combining figure 1 and figure 2 As shown, it is an automatic cabinet door opening and closing mechanism disclosed by the present invention, which includes a cabinet body 1 with one side opening for storage of parcels, vertically arranged and movable on the open end of the cabinet body 1 for closing The cabinet door 2 with the opening of the cabinet body 1, the first linkage assembly 3 arranged inside the cabinet body 1 and located on the top of the cabinet body 1 for driving the cabinet door 2 to open or close the opening of the cabinet body 1, is arranged inside the cabinet body 1 and located at the top of the cabinet body 1 Below the first linkage assembly 3 is a second linkage assembly 4 for keeping the cabinet door 2 in a vertical state, a movable plate 5 arranged horizontally inside the cabinet body 1 and linked with the cabinet door 2 for receiving packages, and arranged on the On one side of the cabinet body 1 is a power output member 7 (not shown in...

Embodiment 2

[0064] Embodiment two: if Figure 8 As shown, the power output member 7 is set as a linear reciprocating device 721 whose movable part is connected to one end of the linkage shaft 31 to drive the linkage shaft 31 to rotate. Specifically, the linear reciprocation device 721 is set as a cylinder body and one side of the cabinet body 1 The second cylinder 721 which is fixedly connected and whose length direction is arranged horizontally along the width direction of the cabinet body 1 is provided with a second drive rod 722 on one side of the movable plate 5, and the second drive rod 722 is far away from one end of the movable plate 5 and the second The piston rod of the cylinder 721 is rotatably connected.

[0065] combine Figure 9 and Figure 10 As shown, a kind of express cabinet that includes the automatic opening and closing mechanism of the cabinet door as described above includes a frame body 8 that is arranged in a rectangular frame shape and has an opening on one side....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com