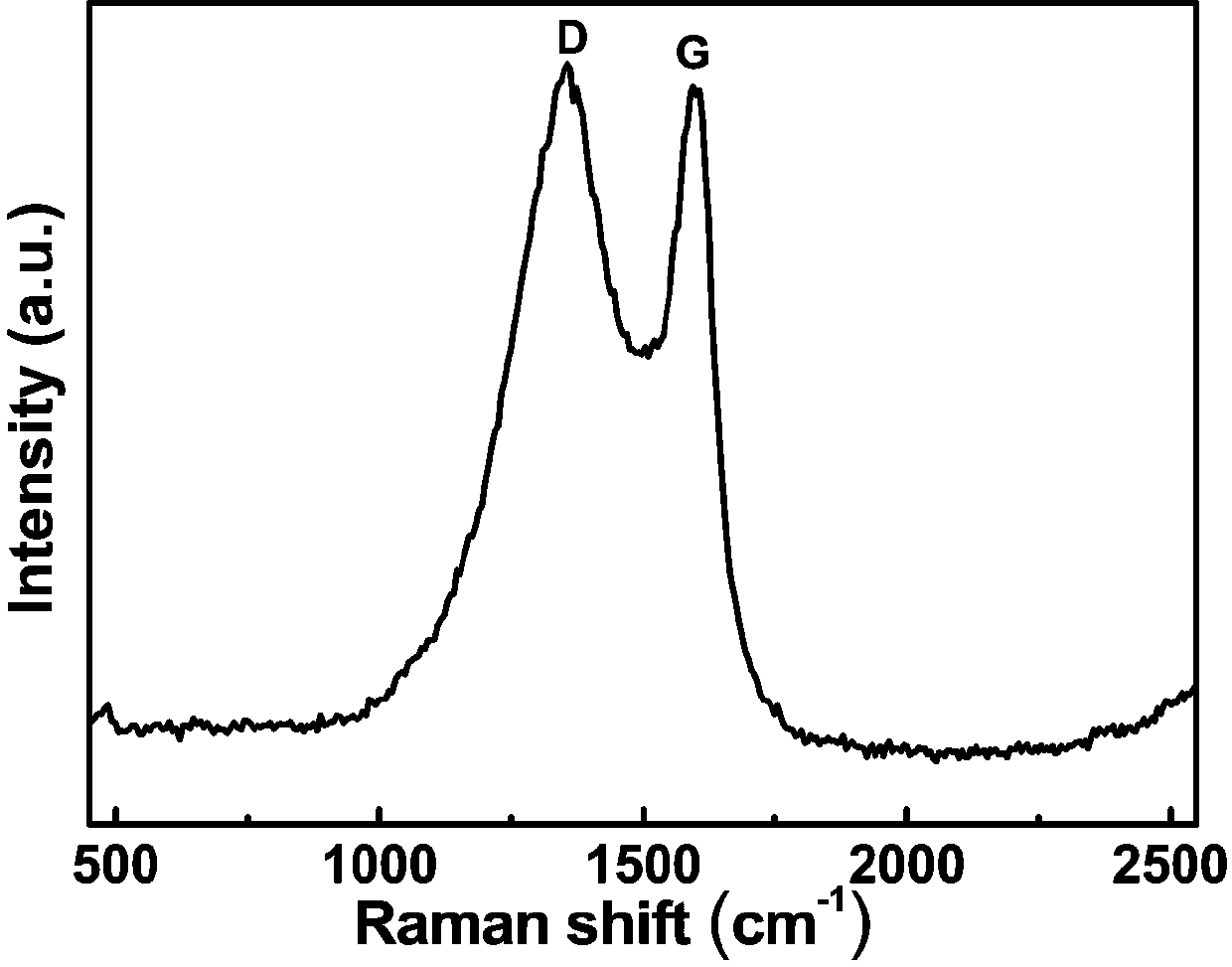

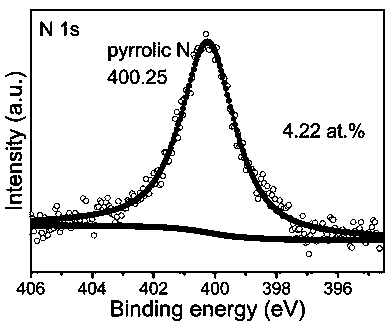

Preparation method of amino phenolic resin-based pyrrole nitrogen-doped carbon electrode material

A technology of aminophenolic resin and nitrogen-doped carbon, applied in chemical instruments and methods, hybrid capacitor electrodes, carbon compounds, etc., can solve the problem of reducing the utilization efficiency of nitrogen-containing functional groups and the proportion of pseudocapacitive sites in nitrogen-doped carbon materials Decrease and other issues, to achieve the effect of high capacity, improved utilization, high pseudocapacitance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A. Dissolve 0.1 g of 3-aminophenol, 0.1 g of 3-fluorophenol and 0.1 g of hexamethylenetetramine in 80 mL of distilled water, and stir at room temperature for 1 h until the solid sample is completely dissolved. Then, this solution was transferred to a 100 mL reaction vessel, at 160 o C for 4 hours, after natural cooling to room temperature, the product was washed with water to pH = 7, and dried to obtain a 3-aminophenol-3-fluorophenol-formaldehyde resin microsphere sample.

[0042] B, the obtained 3-aminophenol-3-fluorophenol-formaldehyde resin microsphere sample in step A is heated from room temperature to 500°C in a nitrogen atmosphere o C, keep warm for 4 hours. Samples were collected after natural cooling to room temperature.

[0043] C. Grind and mix the sample obtained in step B with the activator KOH at a mass ratio of 1 / 6, and then heat from room temperature to 500 °C in a nitrogen atmosphere. o C, keep warm for 8 hours. Naturally cooled to room temperature...

Embodiment 2

[0051] A. Dissolve 0.05 g of 3-aminophenol, 0.15 g of 3-fluorophenol and 0.1 g of hexamethylenetetramine into 80 mL of distilled water, and stir at room temperature for 1 hour until the solid sample is completely dissolved. Then, this solution was transferred to a 100 mL reaction vessel, at 160 o C for 4 hours, after naturally cooling to room temperature, the product was washed with water to pH = 7, and dried to obtain a 3-aminophenol-3-fluorophenol-formaldehyde resin microsphere sample.

[0052] B, the obtained 3-aminophenol-3-fluorophenol-formaldehyde resin microsphere sample in step A is heated from room temperature to 500°C in a nitrogen atmosphere o C, keep warm for 4 hours. Samples were collected after natural cooling to room temperature.

[0053] C. Grind and mix the sample obtained in step B with the activator KOH at a mass ratio of 1 / 6, and then heat from room temperature to 500 °C in a nitrogen atmosphere. o C, keep warm for 8 hours. Naturally cooled to room te...

Embodiment 3

[0057] A. Dissolve 0.025 g of 3-aminophenol, 0.175 g of 3-fluorophenol and 0.1 g of hexamethylenetetramine in 80 mL of distilled water, and stir at room temperature for 1 h until the solid sample is completely dissolved. Then, this solution was transferred to a 100 mL reaction vessel, at 160 o C for 4 hours, after naturally cooling to room temperature, the product was washed with water to pH = 7, and dried to obtain a 3-aminophenol-3-fluorophenol-formaldehyde resin microsphere sample.

[0058] B, the obtained 3-aminophenol-3-fluorophenol-formaldehyde resin microsphere sample in step A is heated from room temperature to 500°C in a nitrogen atmosphere o C, keep warm for 4 hours. Samples were collected after natural cooling to room temperature.

[0059] C. Grind and mix the sample obtained in step B with the activator KOH at a mass ratio of 1 / 6, and then heat from room temperature to 500 °C in a nitrogen atmosphere. o C, keep warm for 8 hours. Naturally cooled to room tempe...

PUM

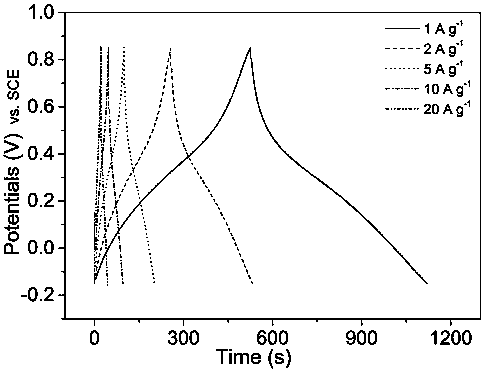

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap