Pressurizing cylinder and clamp device applying same

A technology of pressurizing cylinder and cylinder block, which is applied to fluid pressure actuating devices, chucks, manufacturing tools, etc., can solve the problems of small thrust, inability to clamp workpieces, and unstable cylinder output thrust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

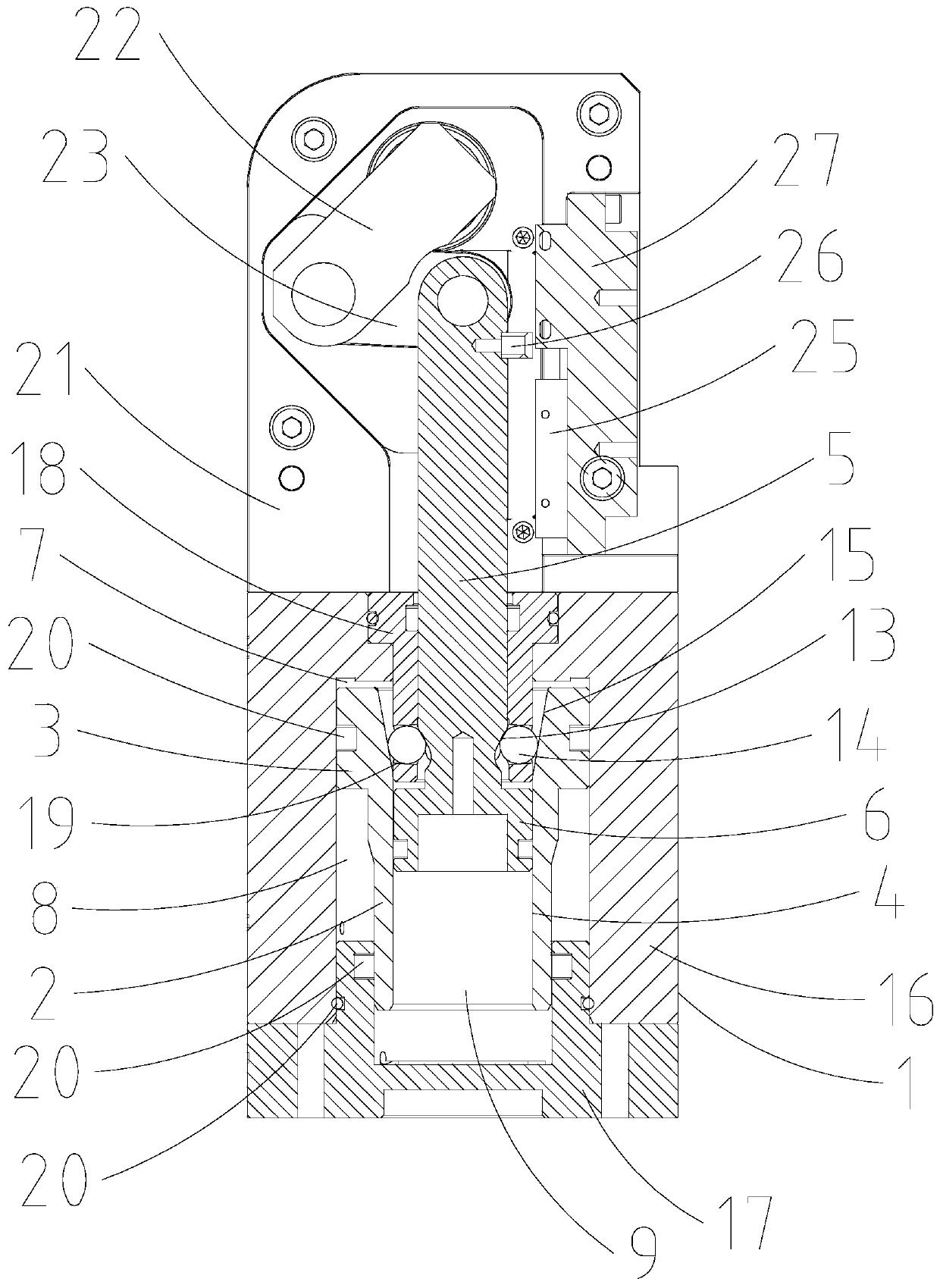

[0044] Such as Figure 1~5 Shown, a kind of pressurized cylinder, it comprises cylinder body 1, first piston part and second piston part; Wherein,

[0045] An inner cavity is provided in the cylinder body 1;

[0046] The first piston part is arranged in the inner cavity, and the first piston part includes a first rod part 2, a first piston part 3 connected to the upper end part of the first rod part 2, and a first piston part 3 passing through the first rod part 2. A rod part 2 and a piston hole 4 of the first piston part 3, the lower end part of the first rod part 2 and the first piston part 3 are both sealed and slidingly connected with the cylinder body 1;

[0047]The second piston part includes a second rod part 5 and a second piston part 6, the second piston part 6 is connected in the piston hole 4 in a sealing and sliding fit, and the lower end of the second rod part 5 is connected to the On the second piston part 6, the upper end of the second rod part 5 protrudes out...

Embodiment 2

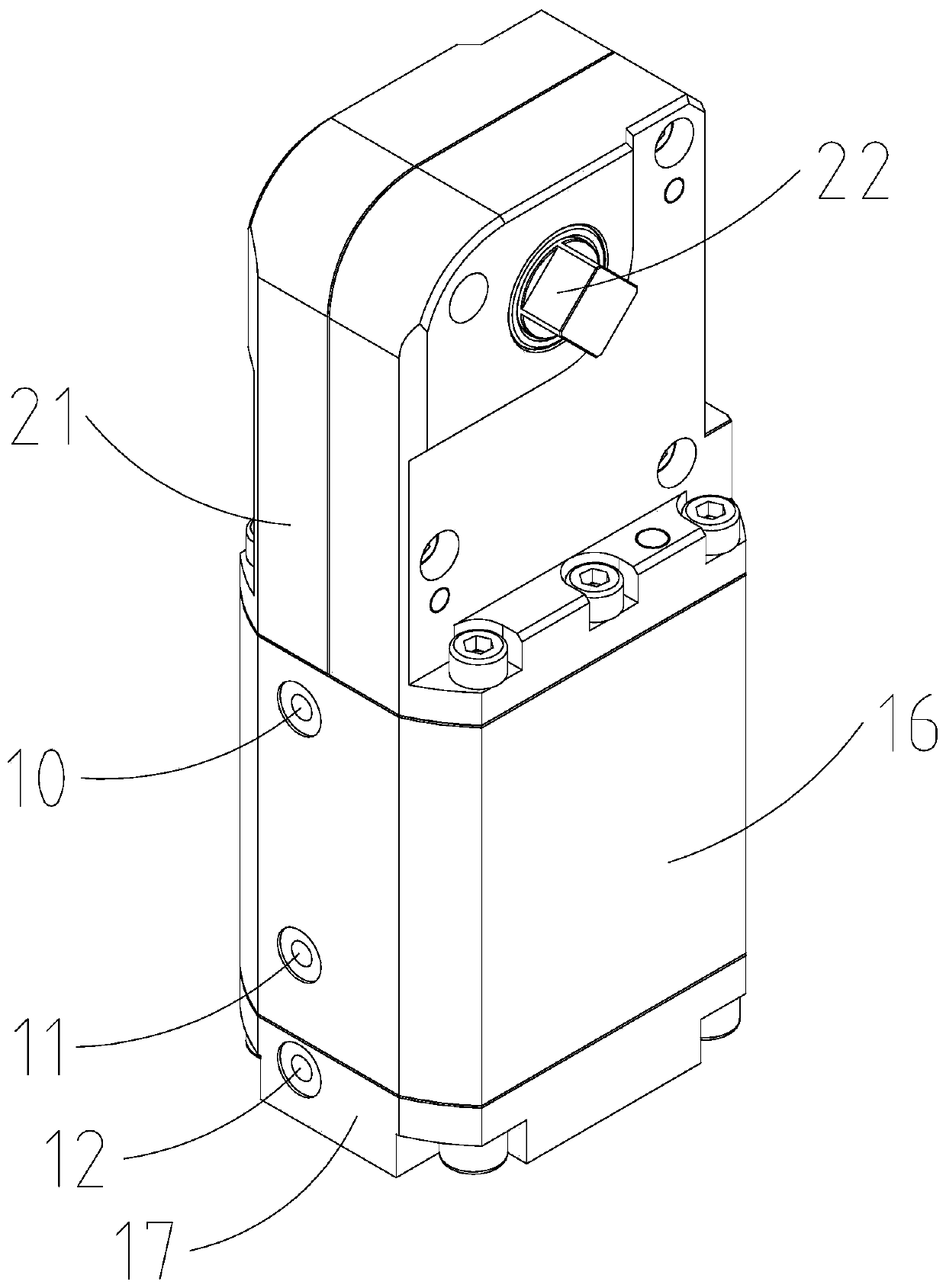

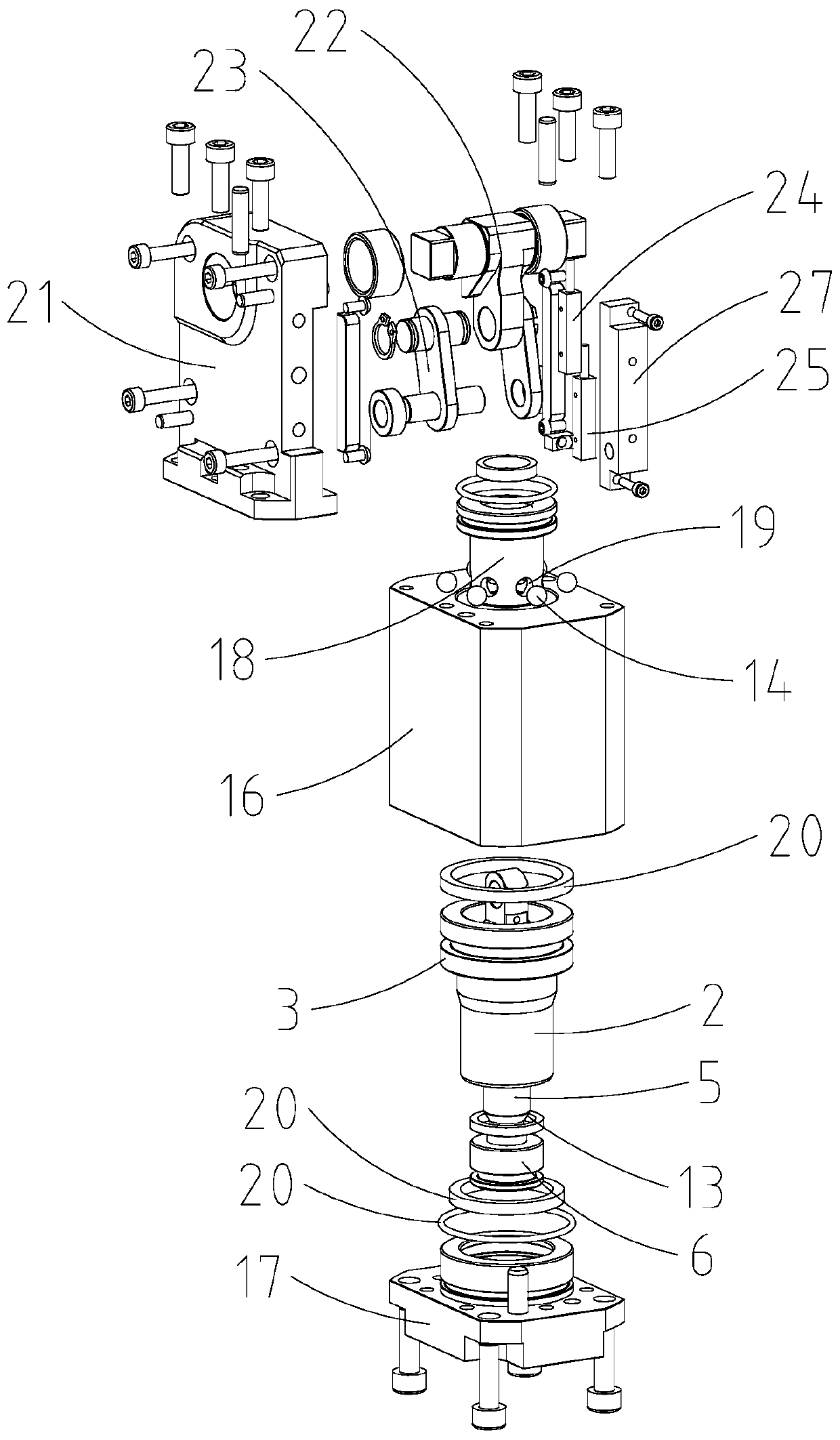

[0066] Such as Figure 1~3 As shown, a clamp device includes the pressurized cylinder described in Embodiment 1, and it also includes a housing 21, a transmission mechanism and a clamping part; wherein,

[0067] The housing 21 is connected to the cylinder 1 or integrated with the cylinder 1;

[0068] The transmission mechanism is connected to the housing 21 and connected to the upper end of the second rod 5;

[0069] The clamping part is connected to the transmission mechanism, so that when the second rod part 5 is driven to move, the second rod part 5 drives the clamping part to act through the transmission mechanism to clamp the external The workpiece; in this embodiment, the housing 21 is connected to the upper end of the cylinder 16 by bolts.

[0070] Such as Figure 1~3 As shown, the transmission mechanism is for example but not limited to the following structure, which includes a crank 22 and a connecting rod 23; wherein,

[0071] The clamping part is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com