Self-operated nitrogen seal valve

A self-operated, nitrogen-sealed technology, applied in lift valve, shaft seal, valve details, etc., can solve the problems of affecting the use effect, not compact, and large volume of the membrane head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

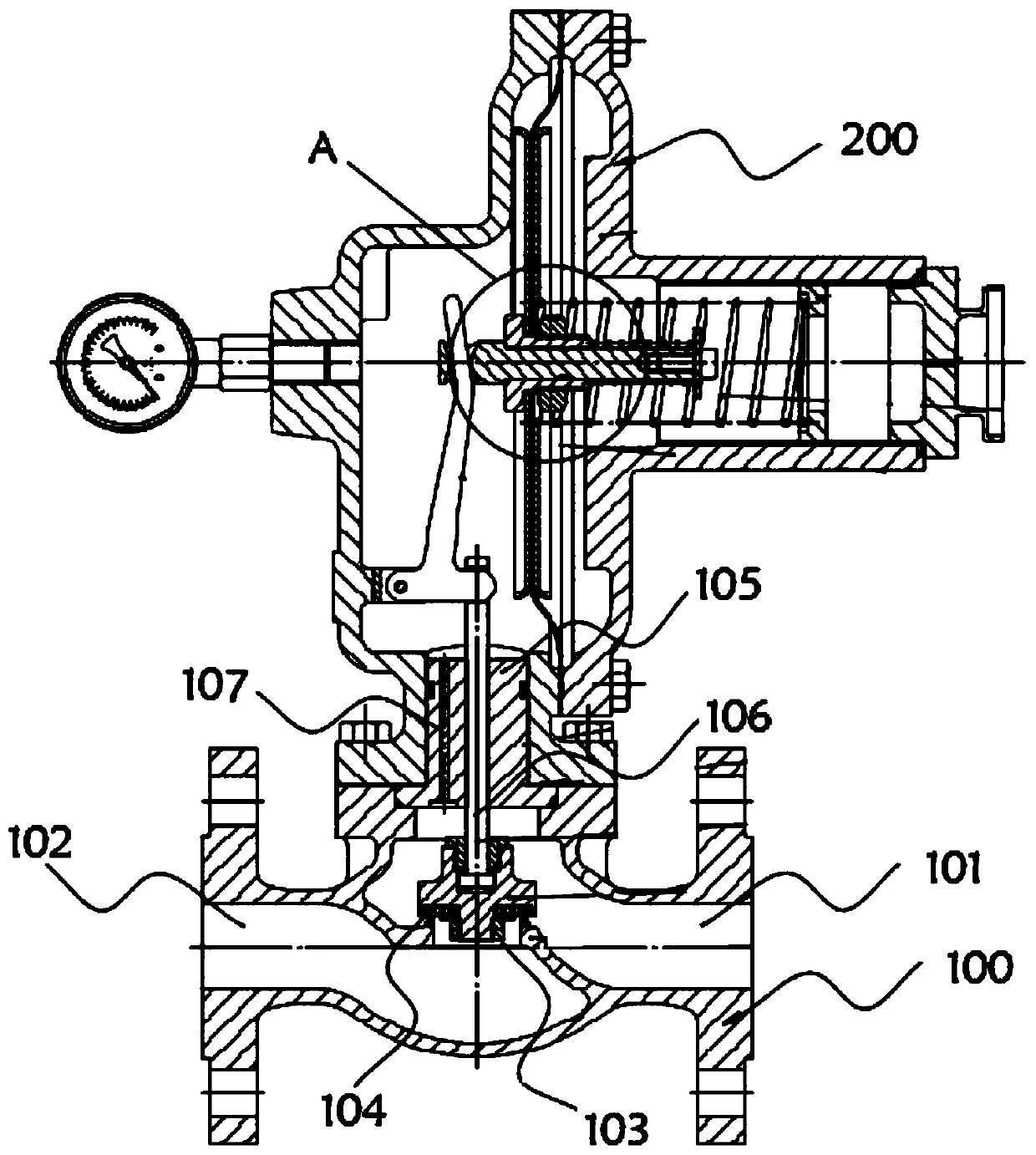

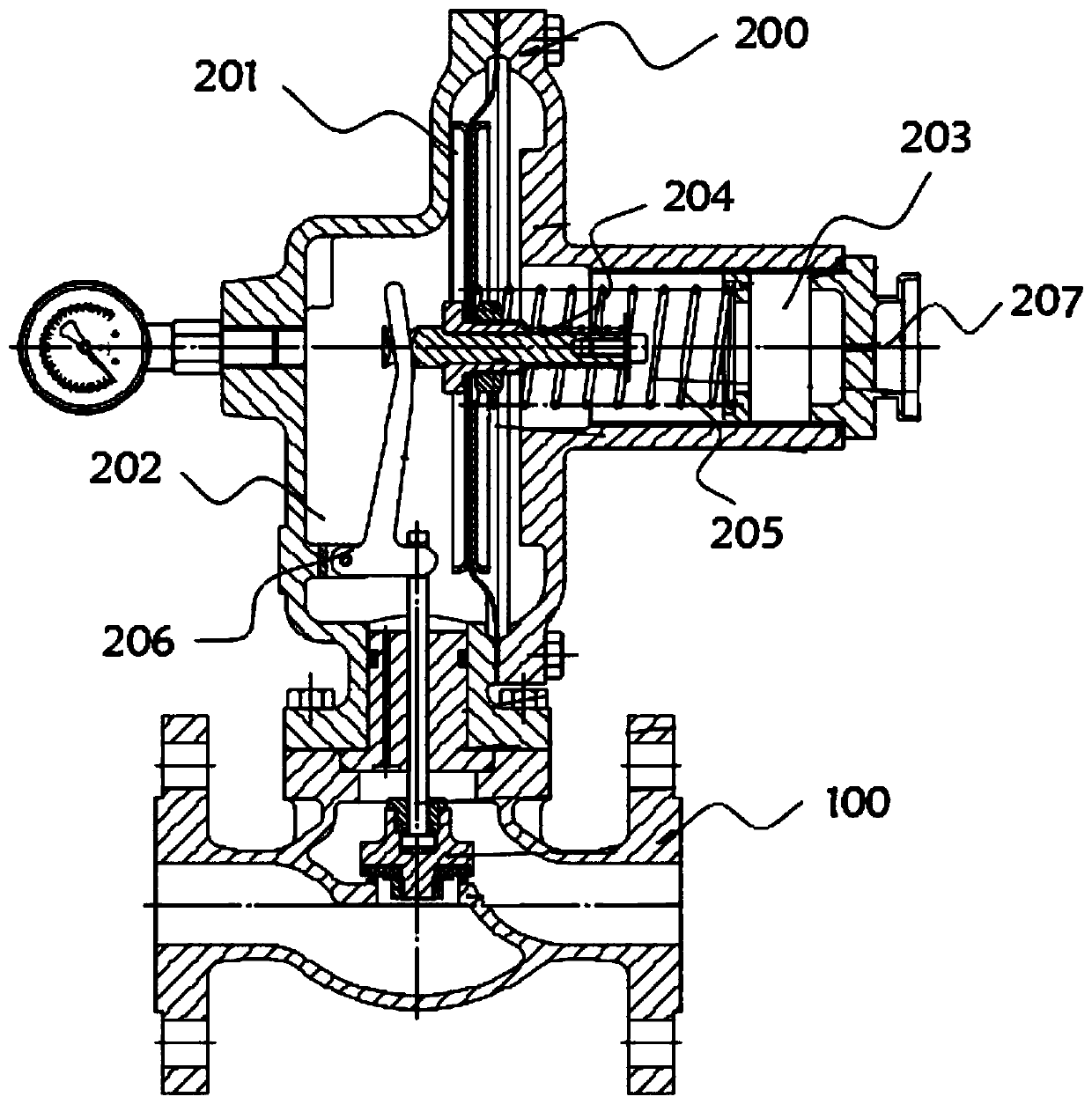

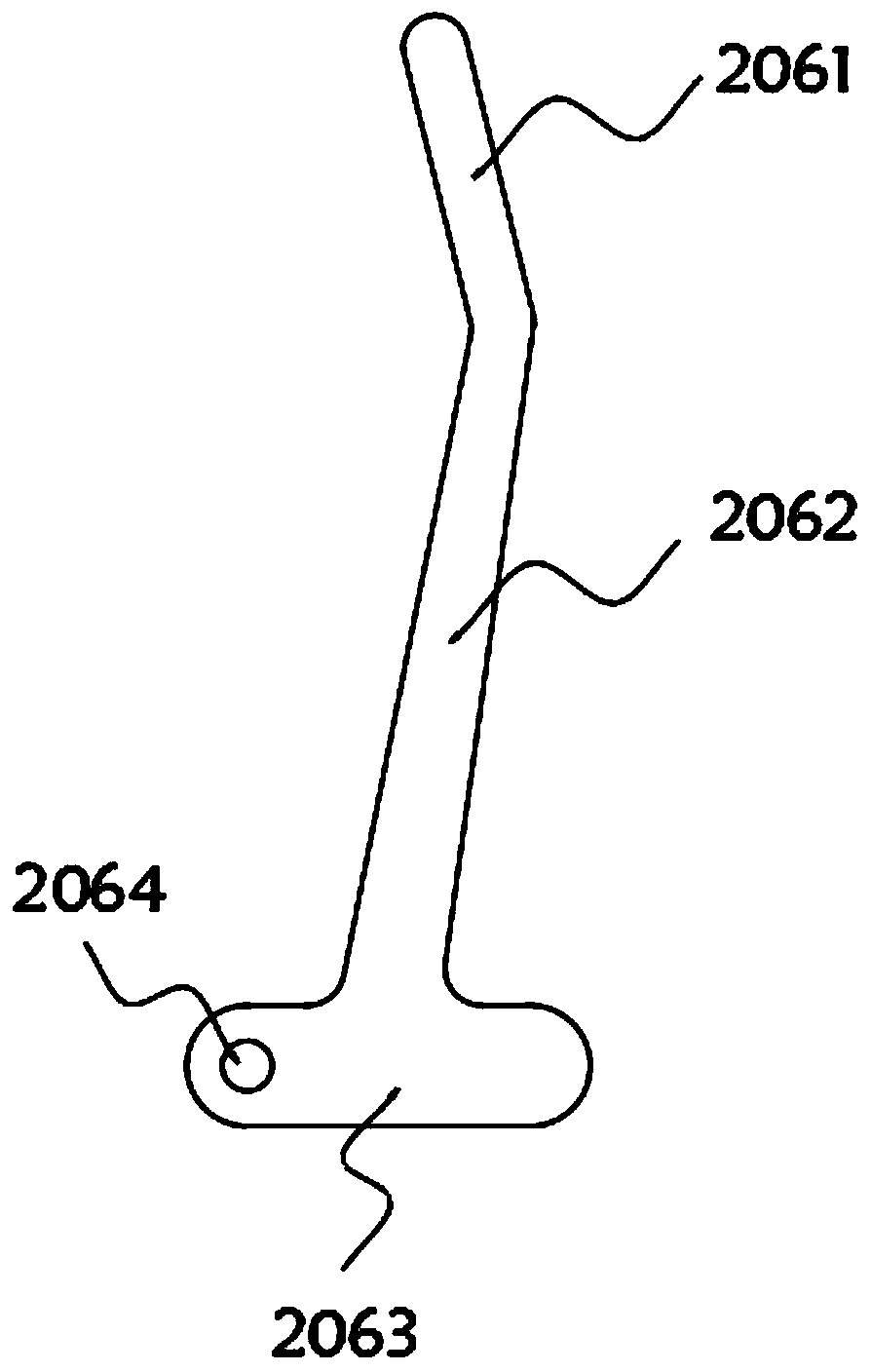

[0032] see Figure 1-Figure 6 As shown, the present invention provides a self-operated nitrogen sealing valve, which includes a valve body 100 and a pneumatic actuator 200 installed on the top of the valve body 100. A diaphragm 201 is installed inside the pneumatic actuator 200, and the diaphragm 201 is made of elastic material. As a result, preferably, the diaphragm 201 is made of rubber material, which has good toughness and can shrink. At the same time, the rubber material is well sealed and can block gas. The diaphragm 201 is vertically installed inside the pneumatic actuator 200 to save pneumatic execution. The occupied area of the internal space of the actuator 200, the diaphragm 201 divides the interior of the pneumatic actuator 200 into a transmission chamber 202 and an exhaust chamber 203, the transmission chamber 202 is used to control the internal gas passage of the valve body 100, and the central position of the diaphragm 201 is installed Ferrule 208 , a push rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com