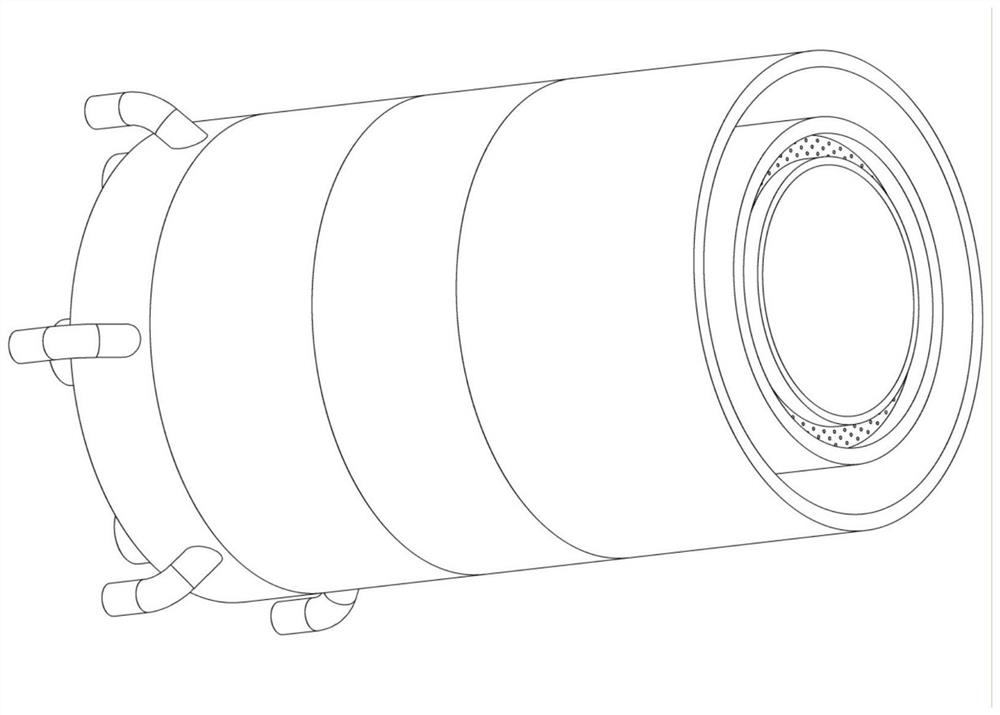

A rotary detonation combustor

A combustion chamber and detonation technology, which is applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of high noise at the outlet of the combustion chamber and low uniformity of fuel mixing, so as to improve combustion efficiency, prolong service life, The effect of extending the axial distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

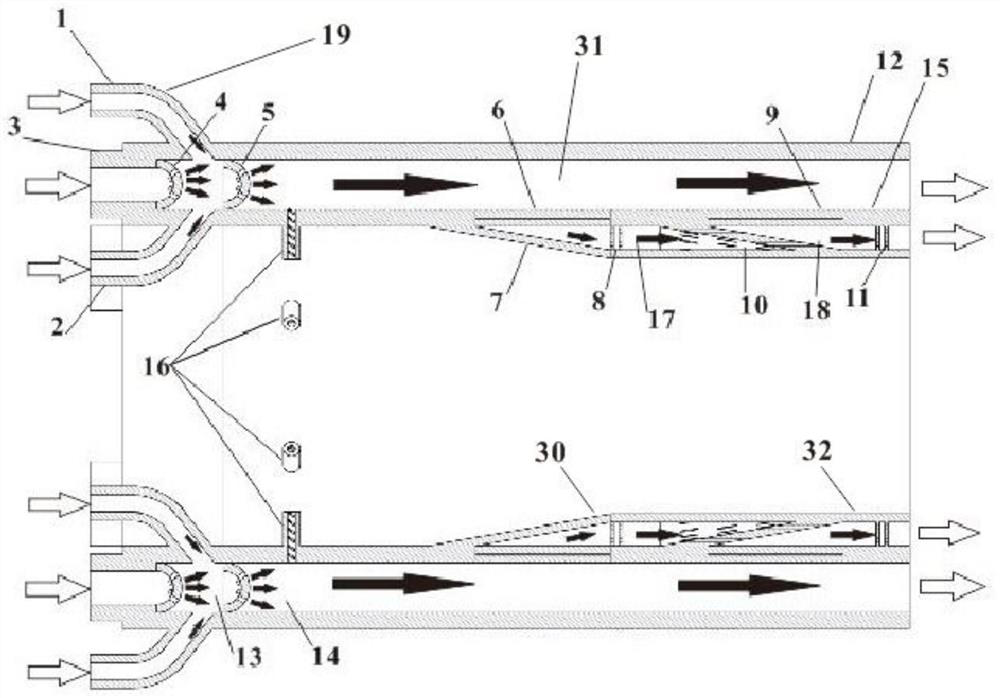

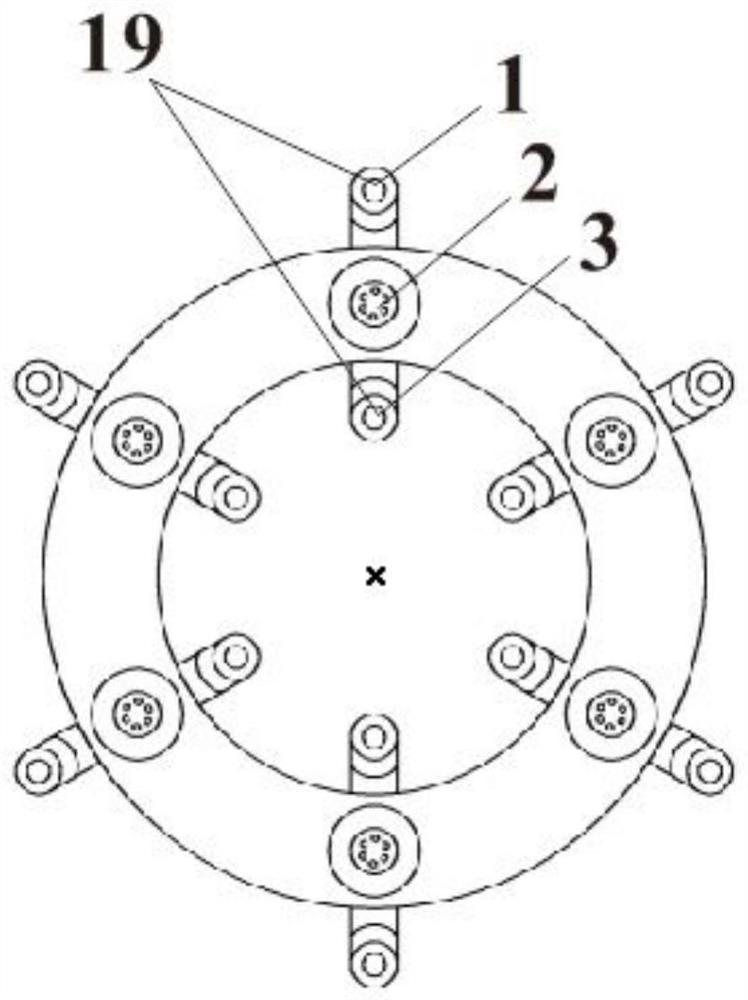

[0020] Such as figure 1 , 2 As shown, a rotary detonation combustor includes an inlet injection device (19), a combustion chamber main annular chamber (31) formed by inner and outer sleeves, an ignition device (16), and a first-stage split channel ( 30) and the secondary shunt channel (32). The inlet injection device (19) is arranged at one end of the main annular chamber (31) of the combustion chamber for injecting the fuel mixture; the ignition device (16) is arranged in the main annular chamber (31) of the combustion chamber and is located at the inlet nozzle Downstream of the injection device (19), one-to-one correspondence with the injection device (19), the first-stage split passage (30) communicates with the second-stage split passage (32), and is successively arranged downstream of the main annular cavity (31) of the combustion chamber and It communicates with the main annular cavity (31) of the combustion chamber. The detonation products are discharged from the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com