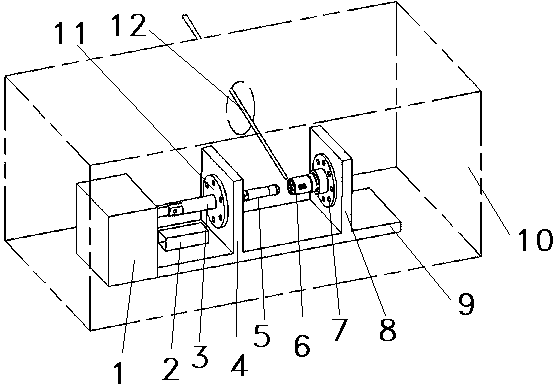

Device and method for testing ablation resistance of moving arc contact

A technology for moving arc contacts and testing devices, which is applied to measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of high cost and high cost when testing the ablation resistance of arc contacts, and achieve low cost , The effect of fast heating and reliable closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

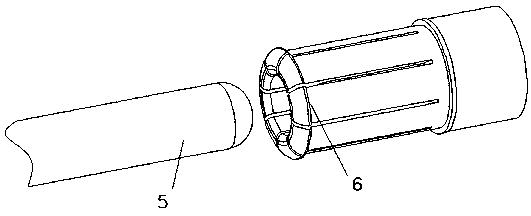

Method used

Image

Examples

specific Embodiment 2

[0050] Specific embodiment 2 of the ablation resistance test device for moving arc contacts of the present application: The difference between this embodiment and specific embodiment 1 is that the static arc contacts are fixed on the fixed frame, and the moving arc contacts move with Close to or away from the static arc contact to realize the uncharged opening and closing of the dynamic and static arc contacts.

specific Embodiment 3

[0051] Specific embodiment 3 of the ablation resistance test device for moving arc contacts of the present application: the difference between this embodiment and specific embodiment 1 is that the moving and static arcing contacts move toward each other to realize the dynamic and static arcing contacts At this time, the closing speed is obtained by adding the moving speeds of the dynamic and static arc contacts.

specific Embodiment 4

[0052] Specific embodiment 4 of the ablation resistance performance testing device for moving arc contacts of the present application: The difference between this embodiment and specific embodiment 1 is that the transition piece is not detachably arranged on the moving arc contact fixing plate, at this time The moving arc contact can reliably maintain its position during the detection process, and this embodiment is suitable for users with relatively single product models.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com