Rotating electrical machine provided with a wedging element

A technology for rotating motors and components, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as insufficient sensor contact, and achieve the effect of improving heat exchange and reducing response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Unless otherwise stated, identical elements shown in different figures have a single reference sign.

[0044] The invention relates to a rotating electrical machine 1 , in particular for a motor vehicle. The rotating electric machine 1 according to the invention may be in the form of an alternator, an electric motor or a reversible electric machine capable of operating in two modes.

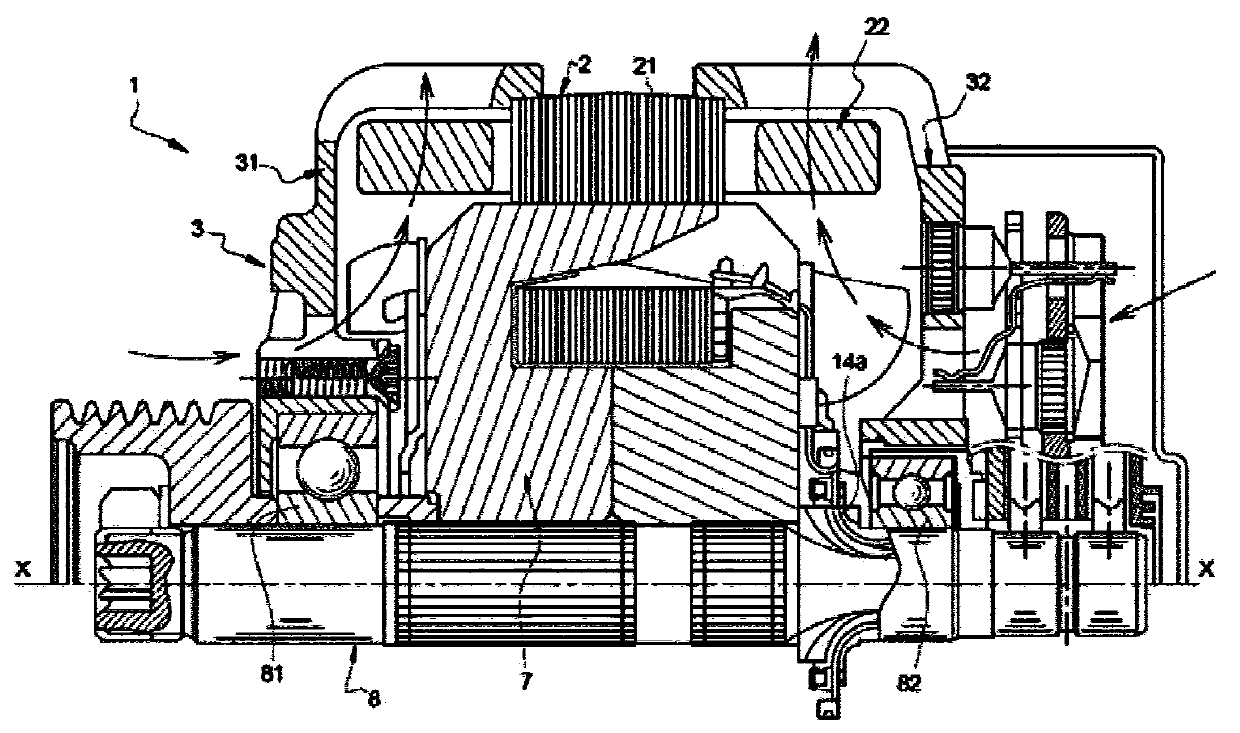

[0045] figure 1 The overall structure of the rotating electric machine 1 is schematically shown.

[0046] refer to figure 1 A rotating electric machine 1 includes a stator 2 and a rotor 7 fitted on a shaft 8 . The shaft 8 is mounted for rotation about the axis of rotation X by means of bearing means 81 and 82 , for example ball bearings. The bearing devices 81 and 82 are supported by the rear support 31 and the front support 32 forming the housing 3 of the rotary electric machine 1 .

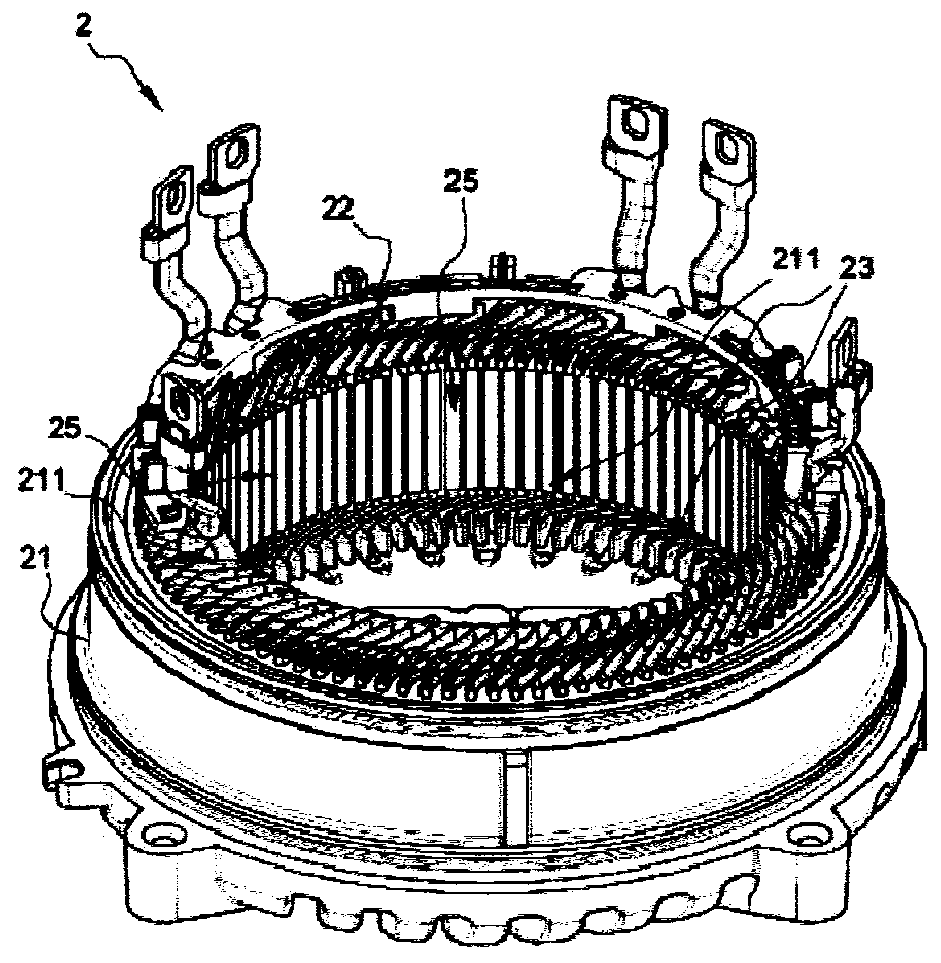

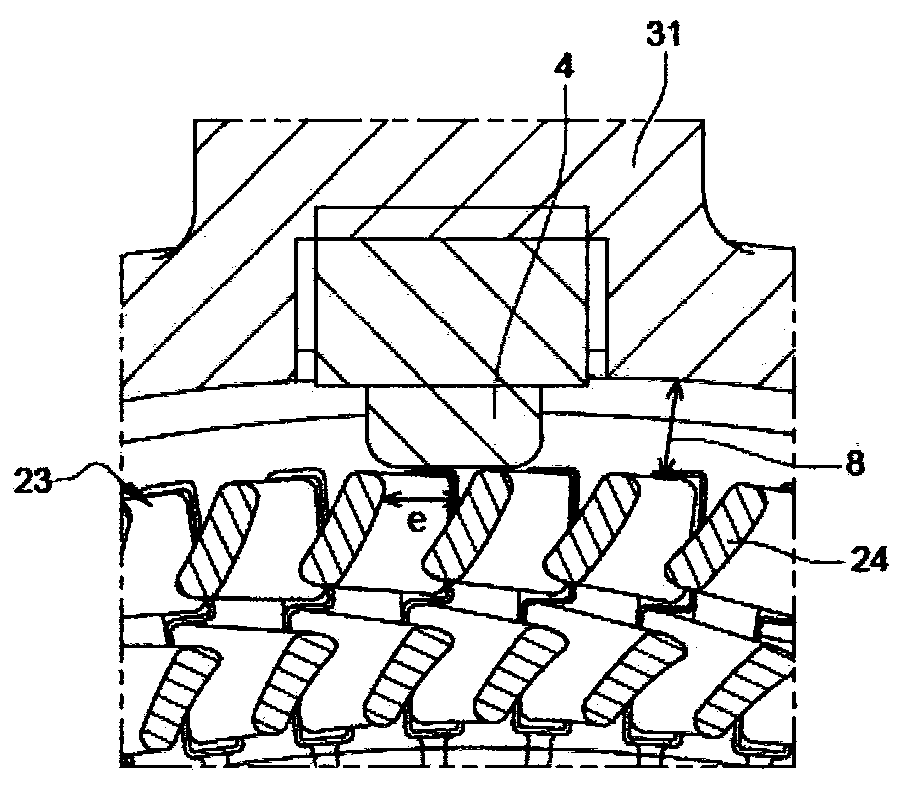

[0047] The stator 2 comprises a main body 21 , supported by the housing 3 , in the form of a stack o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com