Equipment for splicing waistlines of pull-ups

A trouser waist and equipment technology, applied in the field of pull-up trousers manufacturing equipment, can solve problems such as limited pulling force, unstable work, and rising defective rate, and achieve the effects of increasing the ability to resist cracking, stable waist connection, and less energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

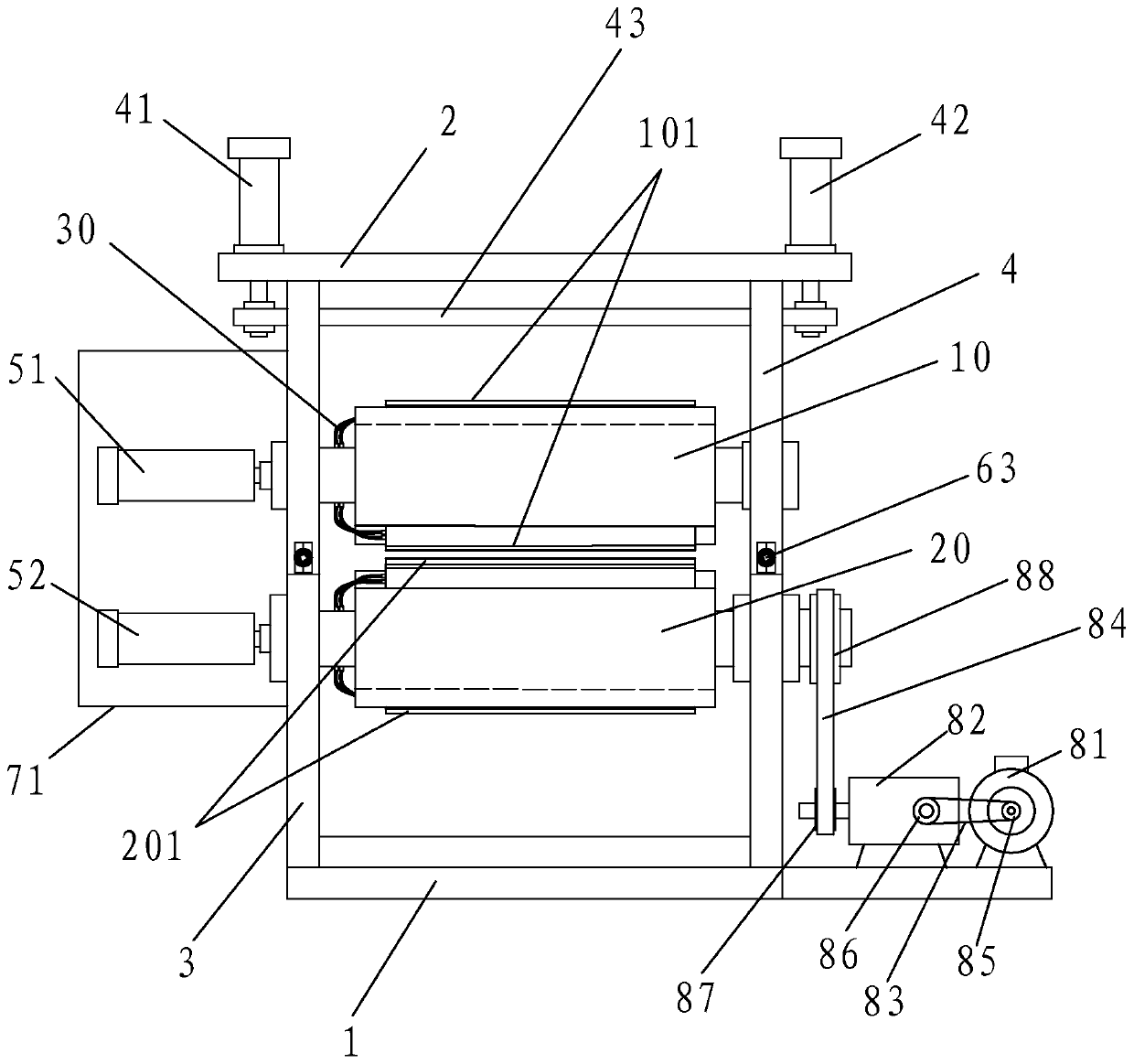

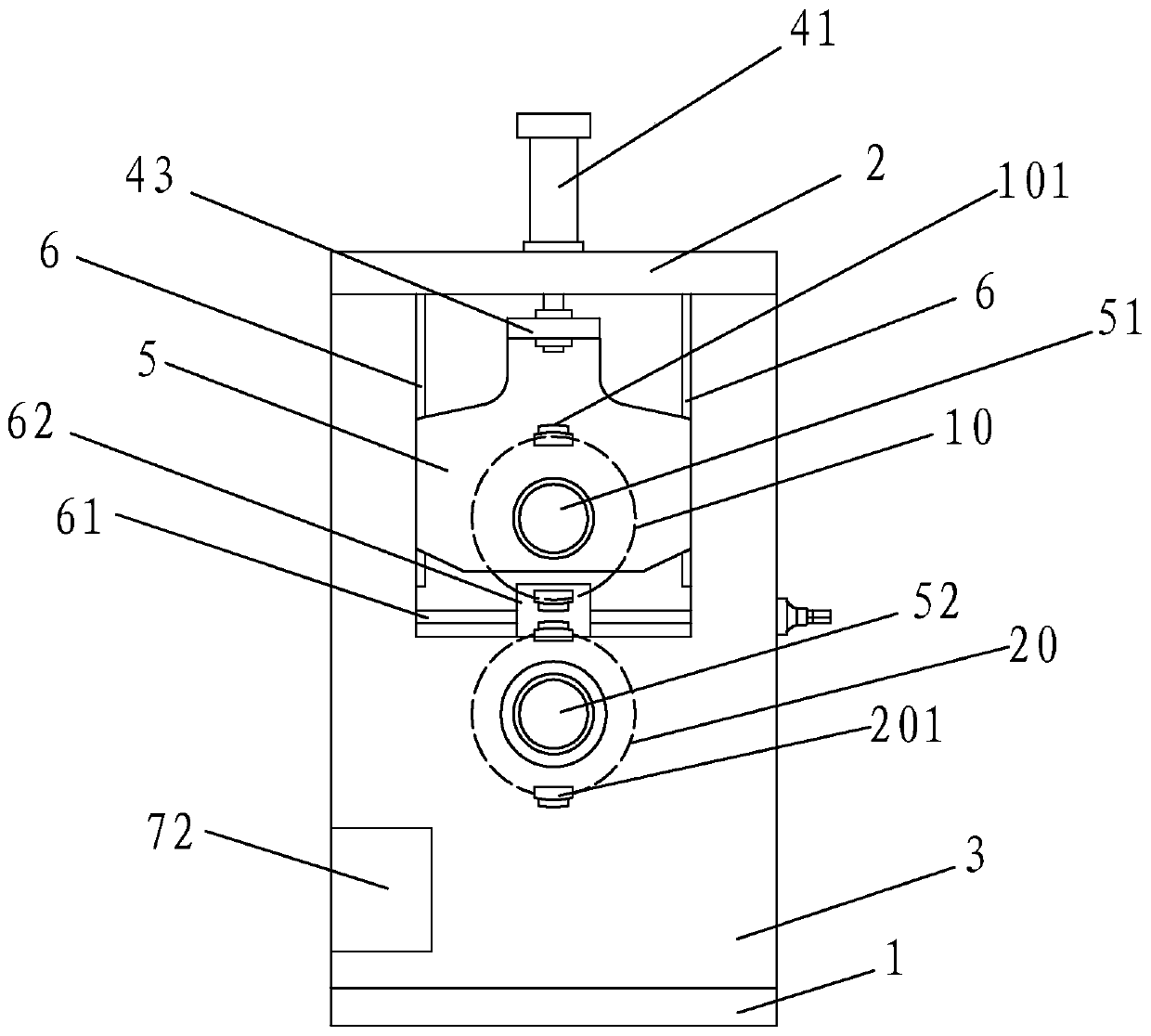

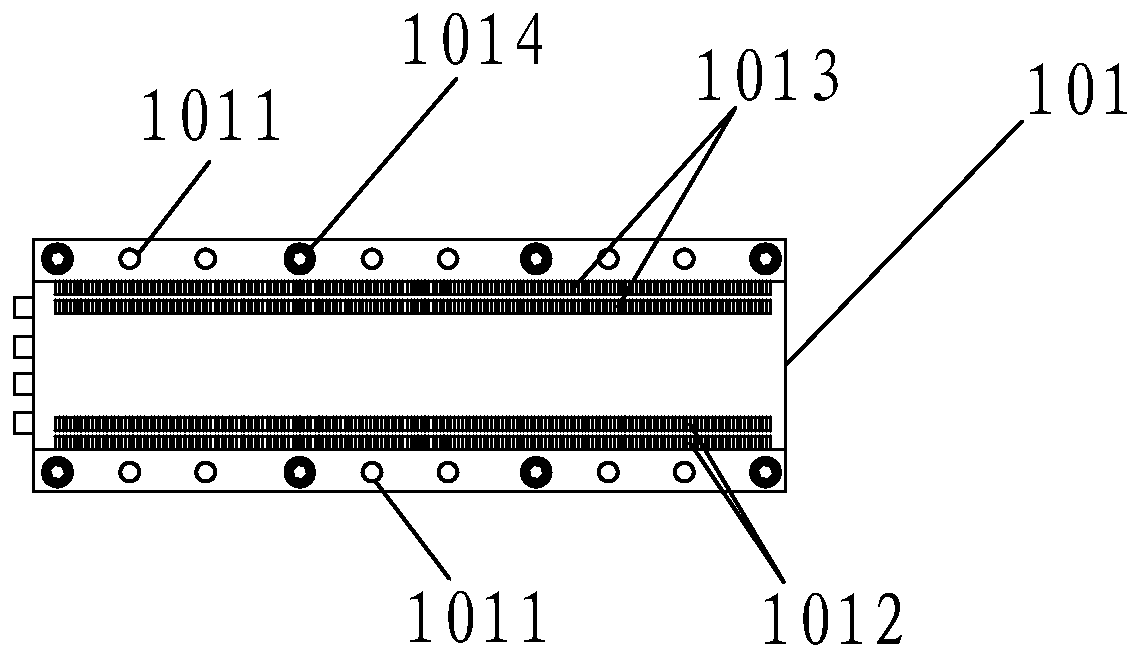

[0027] Such as Figure 1-3 As shown, the device for joining the waistline of pull-up trousers of the present invention includes a frame body, the frame body has a rectangular frame structure, and also includes a horizontal and rotationally mounted The first pressing roller body 10 and the second pressing roller body 20 of the pull-up trousers are transported in the frame body by up and down rolling, the first pressing roller body 10 is above the second pressing roller body 20, Both the first pressing roller body 10 and the second pressing roller body 20 have a central tube with both ends sealed for accommodating heat transfer oil and a solid cylinder wall sleeved outside the central tube. The first pressing roller On the cylinder wall of the body 10, several first pressing teeth 101 for forming two side-by-sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com