A wall polishing path planning method, device, equipment and medium

A path planning and path technology, which is used in grinding/polishing equipment, automatic grinding control devices, metal processing equipment, etc. It can solve the problem that the machine cannot accurately control the grinding depth, cannot guarantee the optimal grinding operation path, and the labor cost is high. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

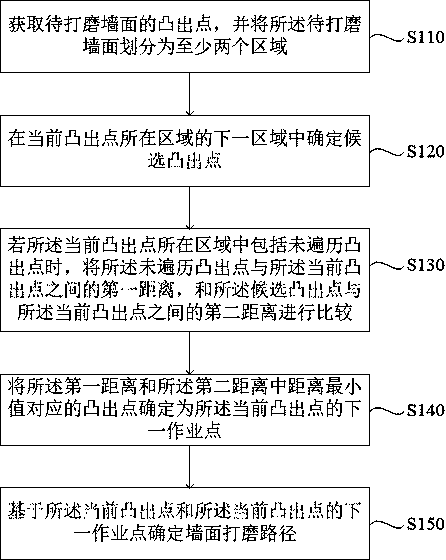

[0036] figure 1 It is a flow chart of a wall grinding path planning method provided by Embodiment 1 of the present invention. This embodiment is applicable to the grinding of protruding points on the wall, and the method can be executed by a wall grinding path planning device. Specifically Including the following steps:

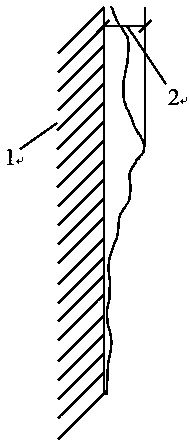

[0037] S110. Obtain the protruding points of the wall surface to be polished, and divide the wall surface to be polished into at least two regions.

[0038] Generally, there will be protruding points on the wall of the construction building that exceed the acceptance standard. At this time, the protruding points need to be polished. Polish path planning. Optionally, dividing the wall surface to be polished into at least two areas includes: dividing the wall surface to be polished into at least two areas according to the size of the grinding equipment, and the width of the area is greater than the diameter of the grinding equipment . If the width of the ar...

Embodiment 2

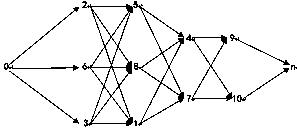

[0057] Figure 6 It is a flow chart of a wall grinding path planning method provided by Embodiment 2 of the present invention. This embodiment is further optimized on the basis of the above embodiments. Optionally, the wall grinding path planning method further includes: for any convex Out of the point, a judgment grid is established, wherein, the judgment grid includes a contour line characterizing the decreasing diffusion trend of the protruding point, and the contour line of the protruding point diffusion trend can provide a basis for the judgment of the grinding direction; based on The contour line determines the single-point grinding path of the protruding point, which avoids uneven grinding and can make the polished wall more conform to the acceptance standard. Such as Figure 6 As shown, it specifically includes the following steps:

[0058] S210. Obtain salient points of the wall surface to be polished, and divide the wall surface to be polished into at least two reg...

Embodiment 3

[0069] Figure 9 A structural diagram of a wall grinding path planning device provided in Embodiment 3 of the present invention, the device includes: an area division module 310, a candidate salient point determination module 320, a distance comparison module 330, a next operation point determination module 340 and The grinding path determination module 350 .

[0070]Among them, the area division module 310 is used to obtain the salient points of the wall surface to be polished, and divide the wall surface to be polished into at least two areas; the candidate salient point determination module 320 is used to locate Determine the candidate salient point in the next area of the area; the distance comparison module 330 is used to compare the untraversed salient point with the current salient point if the area where the current salient point is located includes an untraversed salient point. The first distance between the outgoing points is compared with the second distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com