Formula of cold-resistant and high-oil-resistant non-slip rubber sole

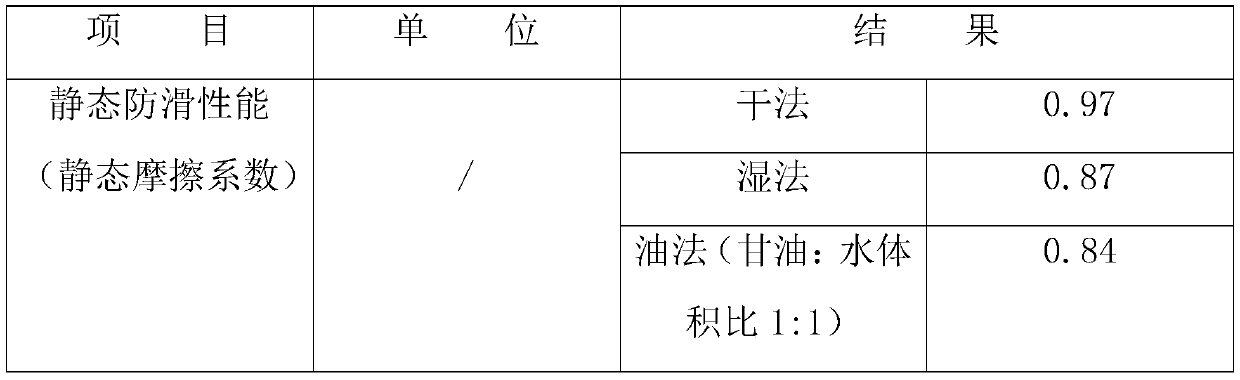

A rubber sole and oil-resistant technology, which is applied in the field of cold-resistant, high-oil-resistant anti-slip rubber sole formulations, can solve the problems of poor anti-slip effect, slippery soles when stepping on oil-stained ground, and affecting wearing safety, etc., to achieve outstanding anti-slip effect and excellent anti-slip ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0022] The present invention provides a cold-resistant, highly oil-resistant anti-slip rubber sole formula:

[0023] A preparation method for cold-resistant and highly oil-resistant anti-slip rubber soles, the formula comprising: NBR nitrile rubber, rubber reinforcing agent, cold-resistant toughening agent, nanometer rubber activator A, silica activator, silane coupling agent, Rubber vulcanization activator B, rubber anti-aging agent, plasticizer, rubber vulcanizing agent, rubber vulcanization auxiliary agent, the steps include: material preparation, primary plasticizing, primary sheet output parking, secondary plasticizing, secondary sheet output parking, mixing Refining, three times of film parking, vulcanization and molding:

[0024] (1) Prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com