Air compressor

An air compressor and piston technology, applied in the field of four-piston air compressors, can solve the problems of high maintenance cost, unstable commutation, poor reliability, etc., to improve the service life and work stability, and reduce the external size and weight. , the effect of reducing pressure and flow pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

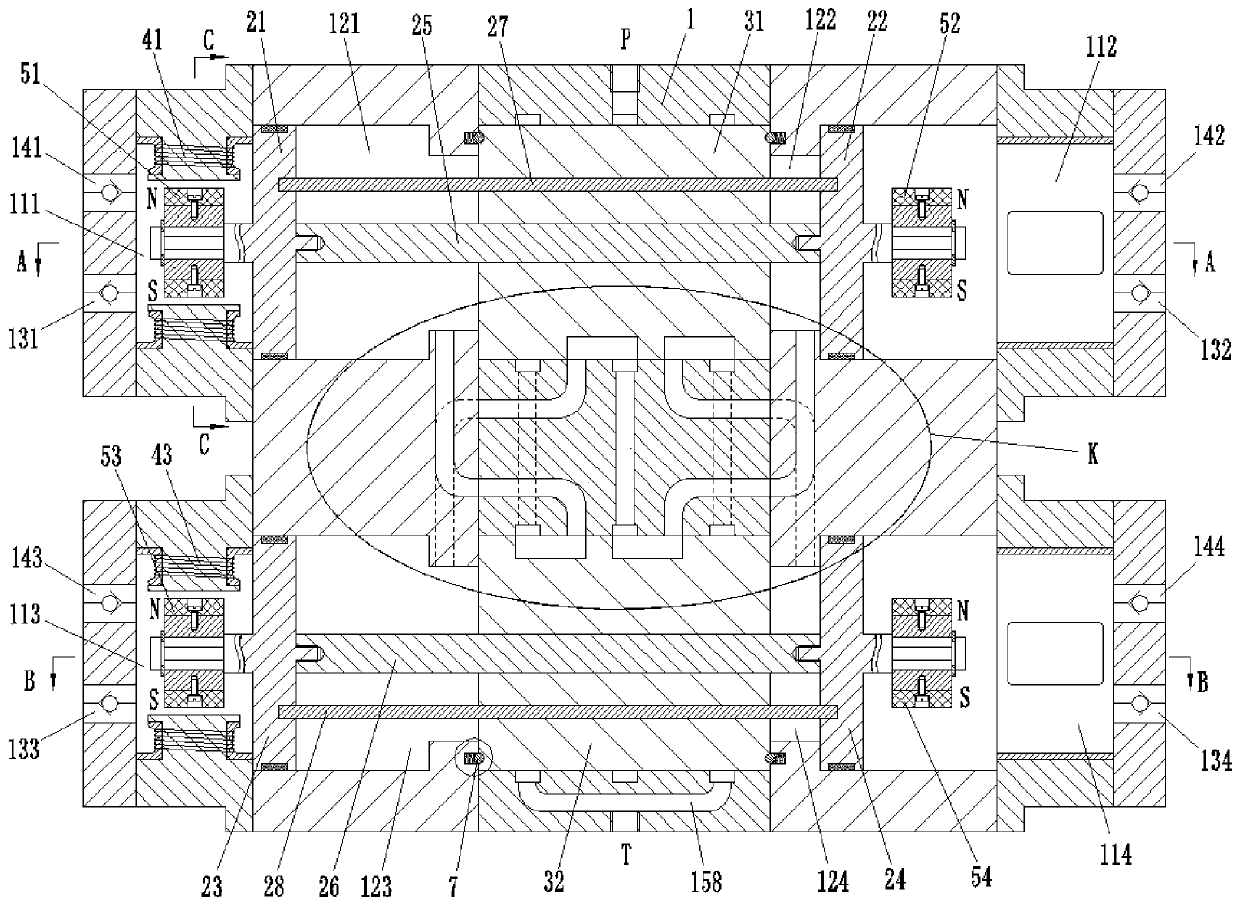

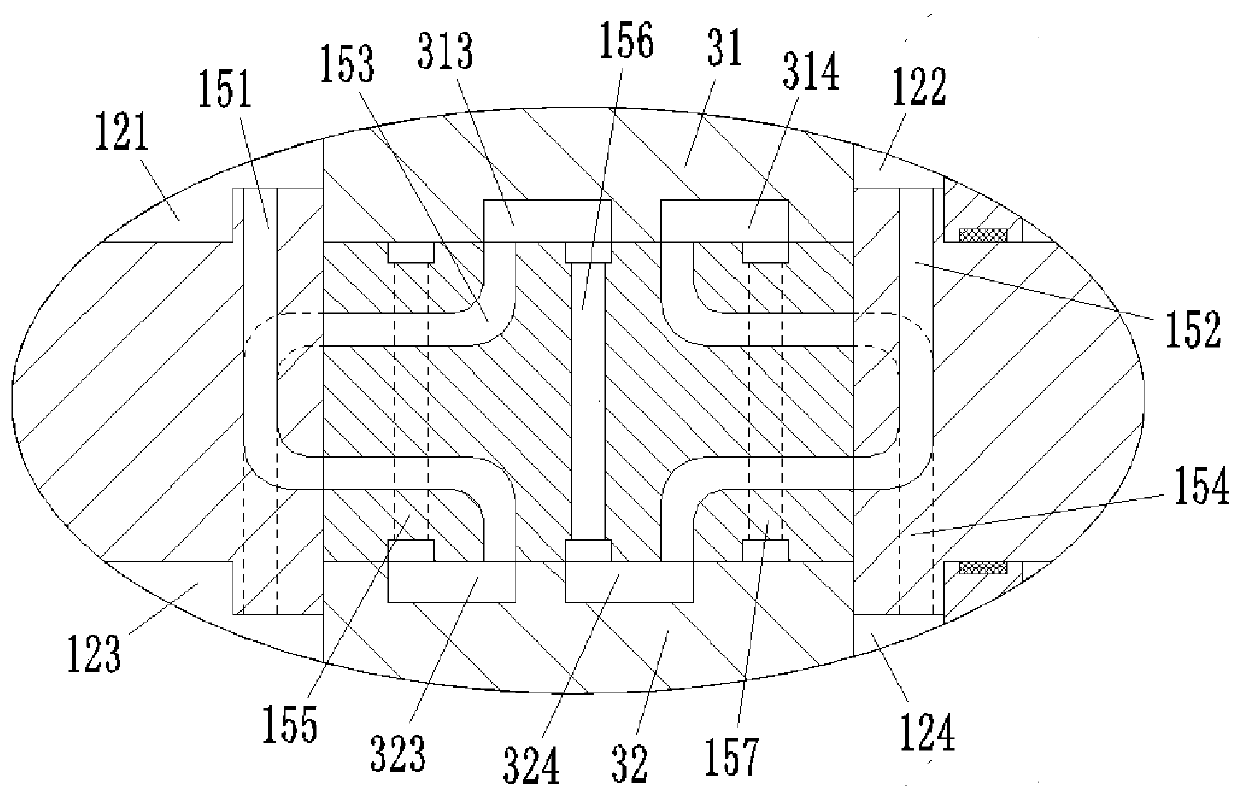

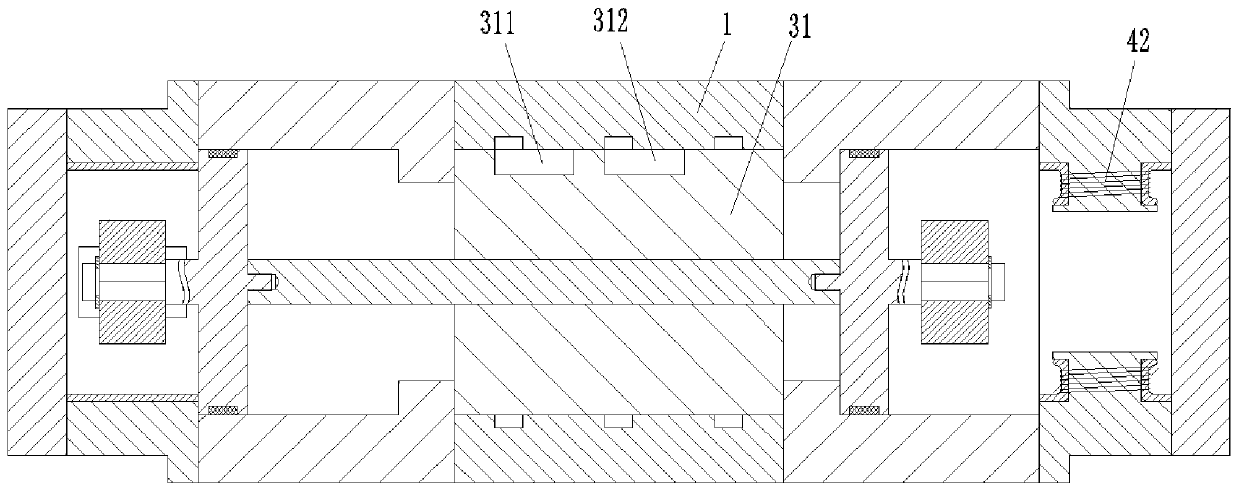

[0044] combine figure 1 As shown, the air compressor of this embodiment includes a housing 1 , a first piston 21 , a second piston 22 , a third piston 23 and a fourth piston 24 . Wherein, the first piston 21 and the second piston 22 are coaxially fixedly connected through the first connecting rod 25 to realize synchronous movement, and the third piston 23 and the fourth piston 24 are coaxially fixedly connected through the second connecting rod 26 to realize synchronous movement.

[0045] Inside the housing 1, there are mutually independent first air chamber 111, second air chamber 112, third air chamber 113 and fourth air chamber 114, as well as first control chamber 121, second control chamber 122, third control chamber Room 123 and a fourth control room 124 . Wherein, the first air chamber 111 and the first cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com