Novel hydraulic coupling device

A coupling device and hydraulic technology, which is applied in the field of coupling sleeves, can solve the problems of laborious disassembly, time-consuming installation and disassembly, and increased cost of use, and achieve the effects of convenient disassembly and maintenance, convenient torque adjustment, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

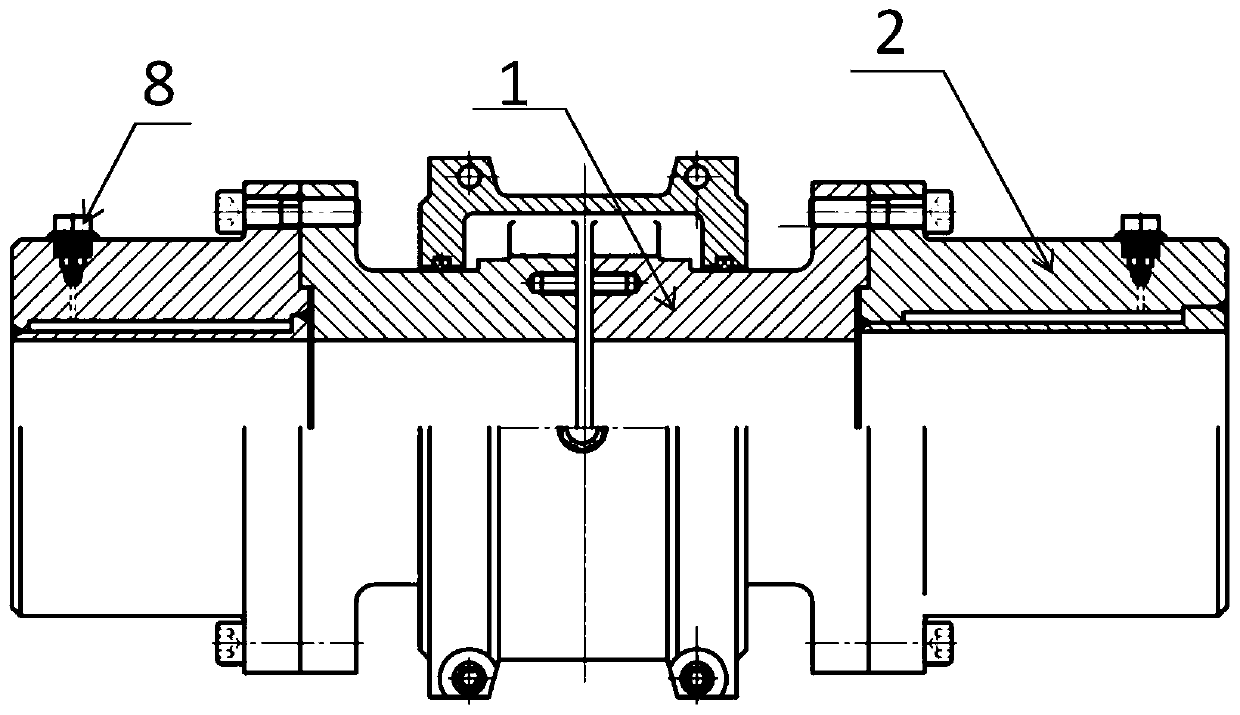

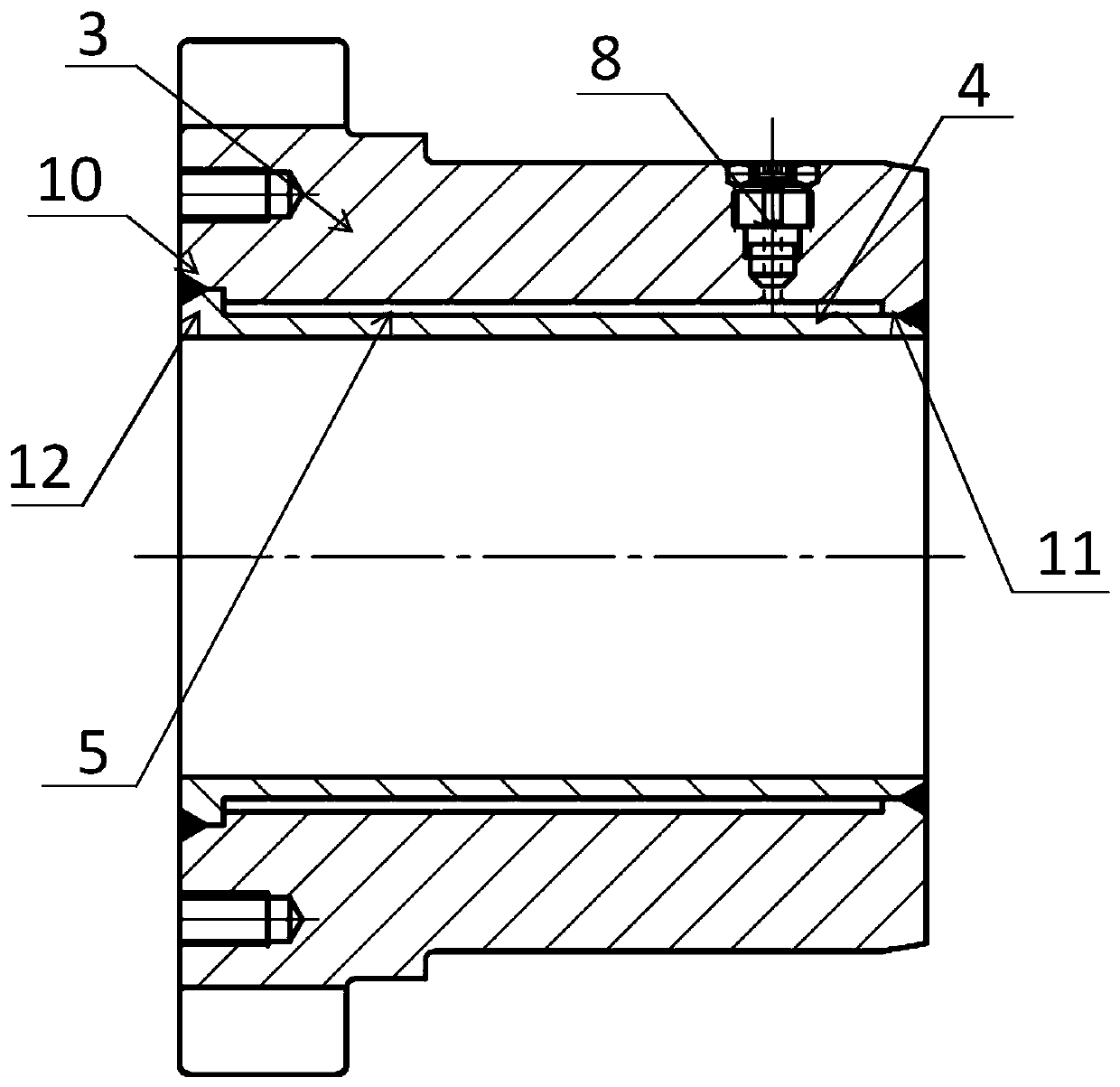

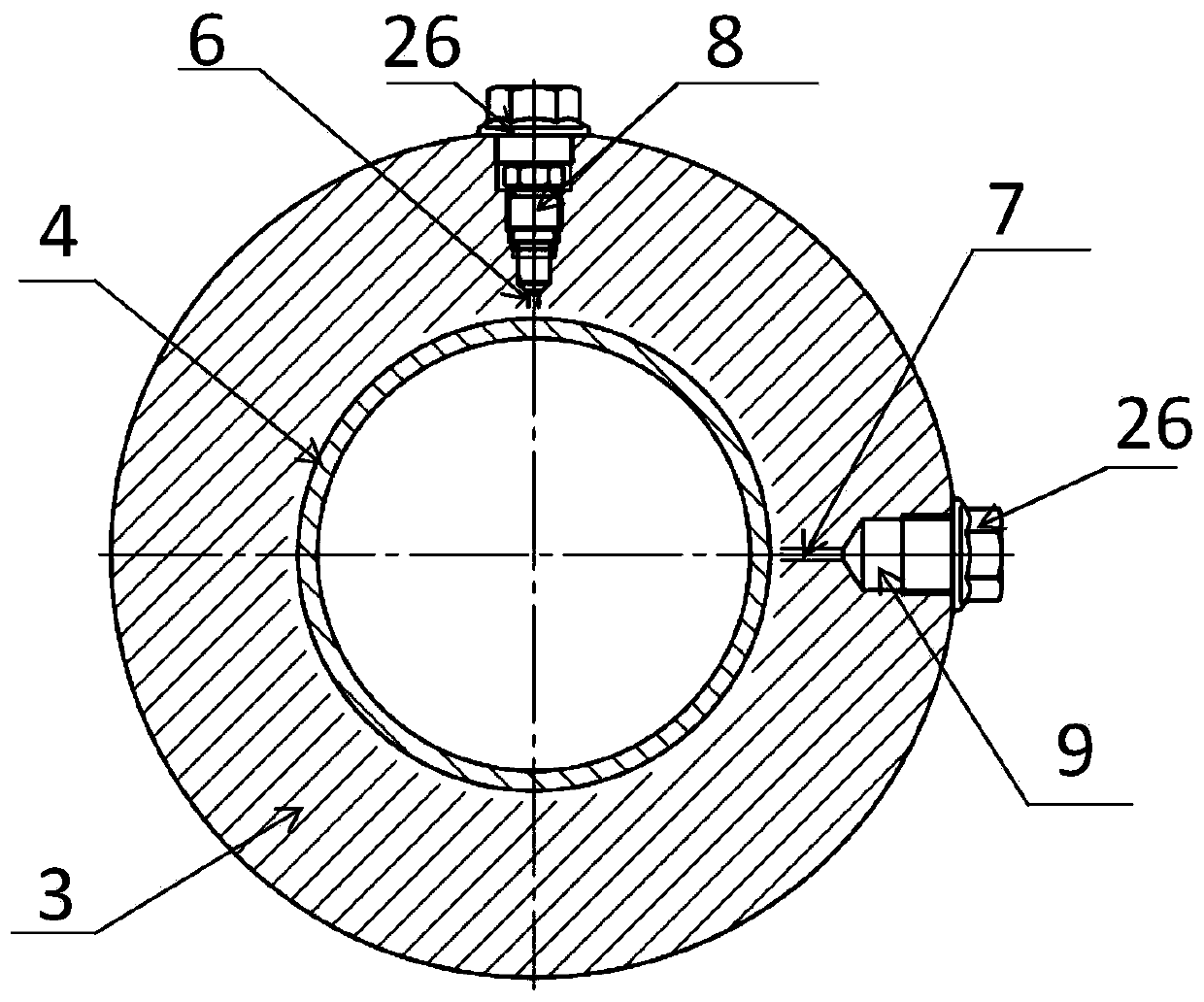

[0034] refer to Figure 1 to Figure 5 As shown, a new type of hydraulic coupling device in this embodiment includes a coupling piece 1 and a coupling sleeve 2 arranged on both sides of the coupling piece 1, and the coupling sleeve 2 includes an outer body 3 connected to the coupling piece 1 and The inner wall pressure sleeve 4 is arranged in the outer casing 3, the inside of the outer casing 3 is hollow, and an annular flange is provided at one end, and a plurality of through-hole teeth are arranged on the annular flange, and the through-hole teeth are used for corresponding connectors The through-hole teeth on 1 are fixedly connected by threaded nuts. The inner hole of the outer casing 3 matches the outer circle of the inner wall pressure sleeve 4. One side of the inner wall of the outer casing 3 is provided with a limit groove 10, and the other The side is provided with an annular projection 11, and the side of the inner wall pressure sleeve 4 in contact with the limit groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com