Aerosol sample sampling device capable of realizing automatic sampling

A technology of automatic sampling and sampling device, applied in sampling device, sampling, measuring device and other directions, to achieve the effect of sampling safety, light weight and improving sampling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

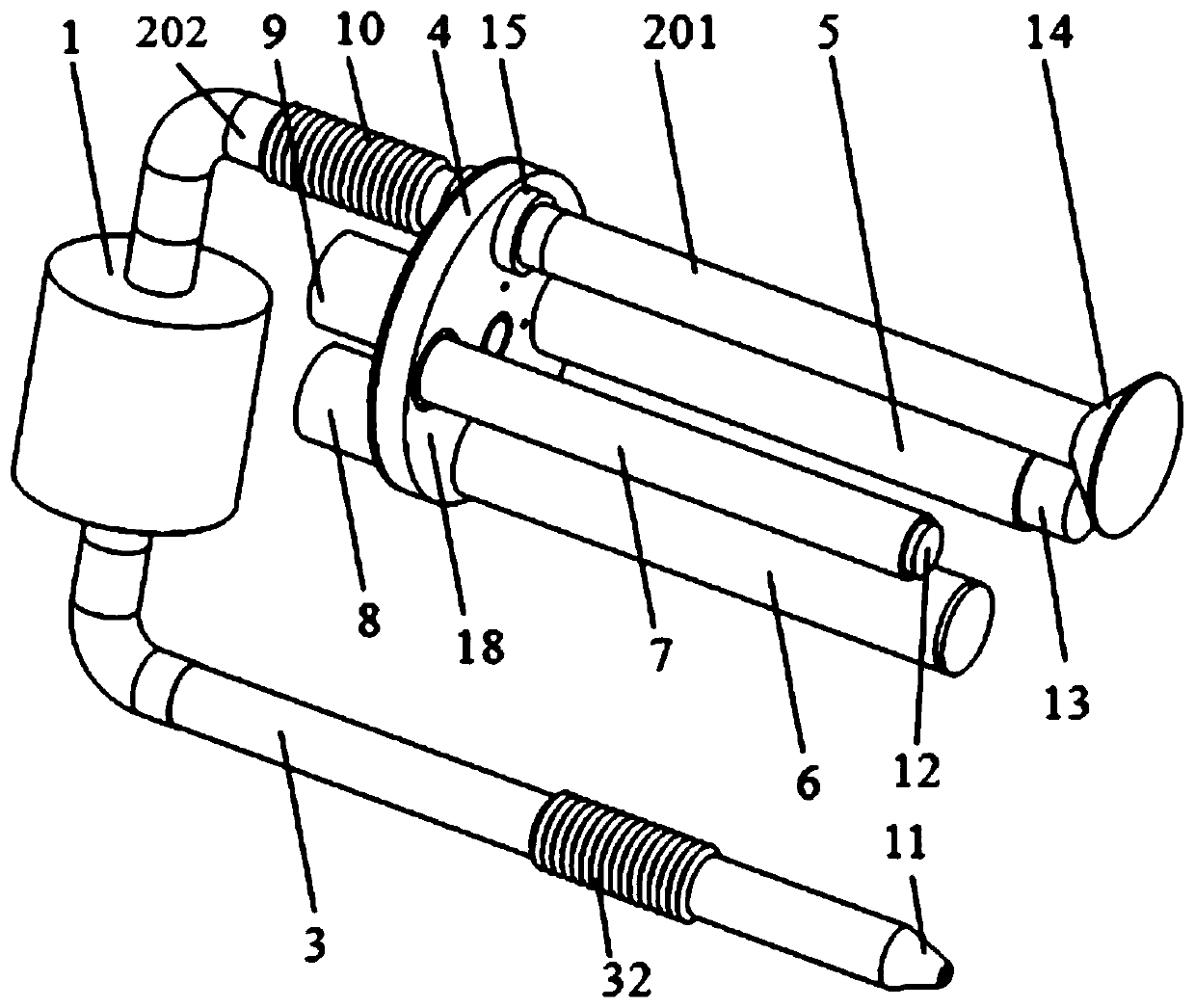

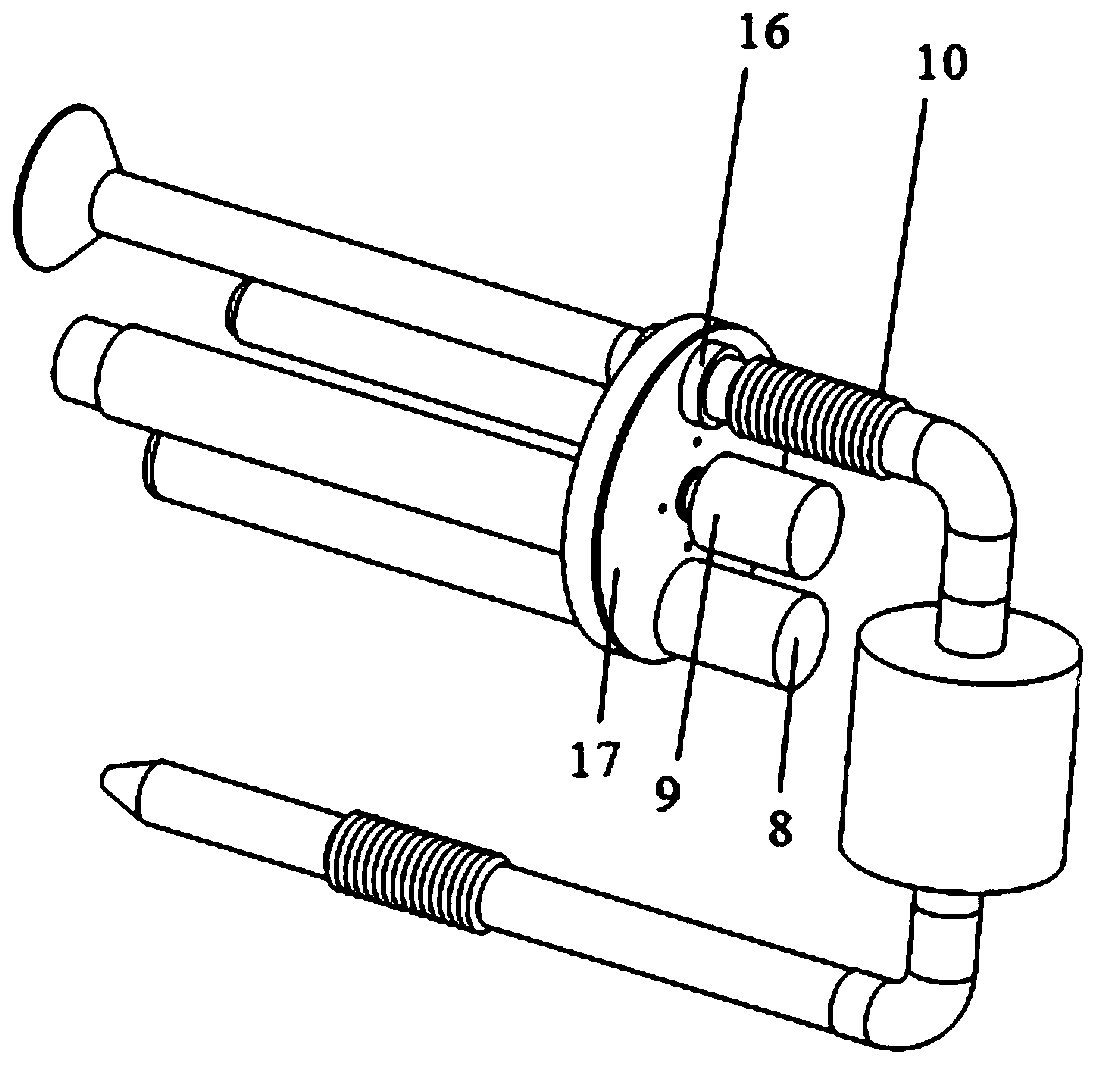

[0059] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

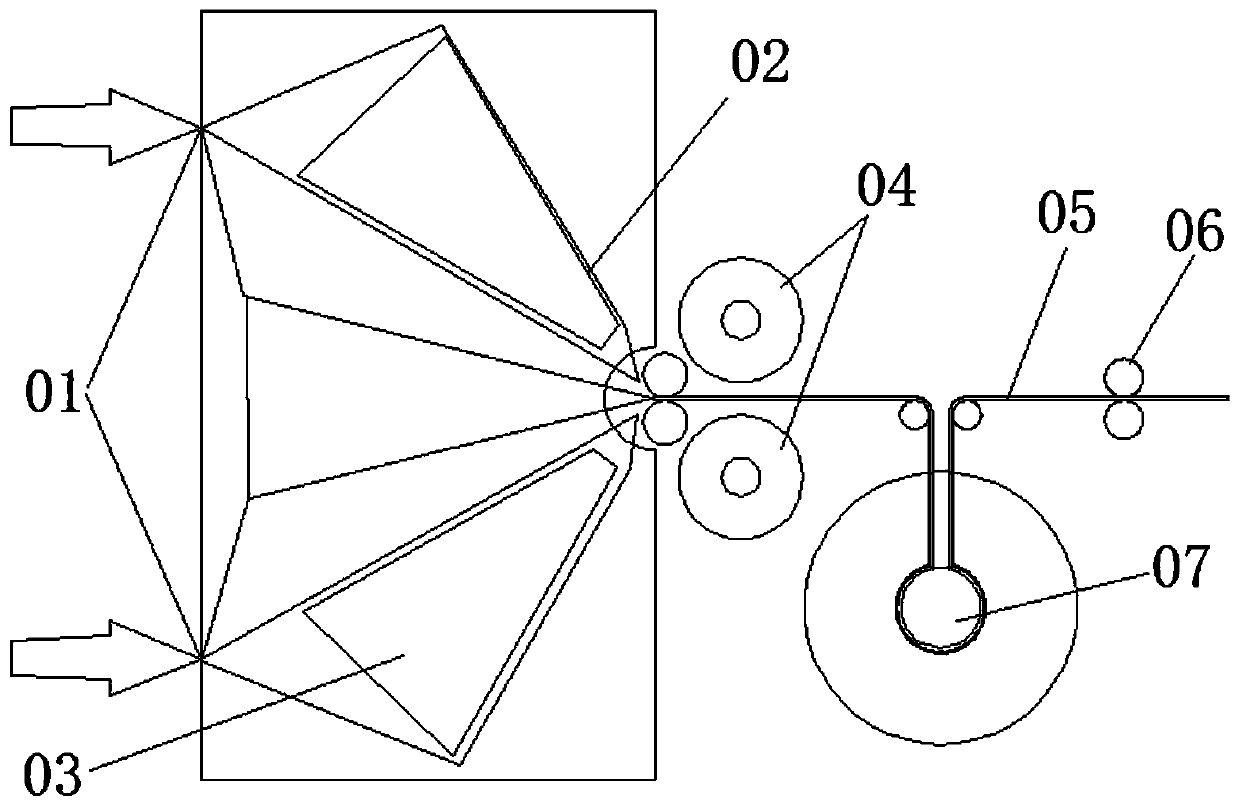

[0060] see figure 2 , image 3 and Figure 4 , the present invention is an aerosol sample sampling device that can realize automatic sampling, including a filter material loading and unloading unit, a gas circuit unit, a plurality of filter material units 24 and a plurality of filter material plugs 29 .

[0061] The filter material loading and unloading unit includes a turntable unit 4 , a filter material storage tube 5 , a filter material plug storage tube 7 , a filter material recovery tube 6 , a filter material drive motor 13 , a plug drive motor 12 and a filter material recovery motor 8 .

[0062] The turntable unit 4 comprises a rear protective cover 17, a front protective cover 18, a turntable 19 and a turntable drive motor 9; the front protective cover 18 and the rear protective cover 17 are fixedly connected to form a cavity; the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com