Polyurethane mattress with internal airflow adjusting function

A technology of airflow adjustment and polyurethane, which is applied in the field of mattresses to achieve the effect of increasing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

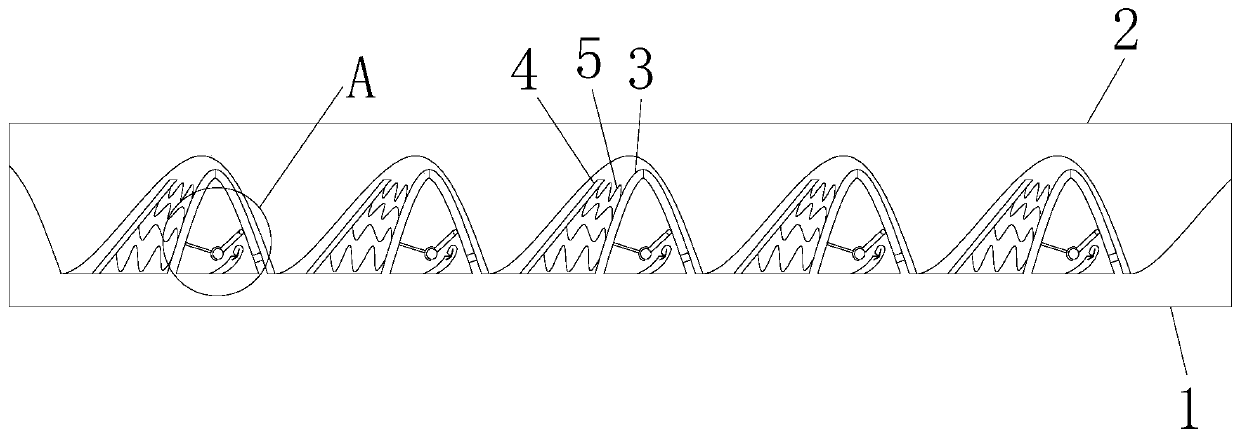

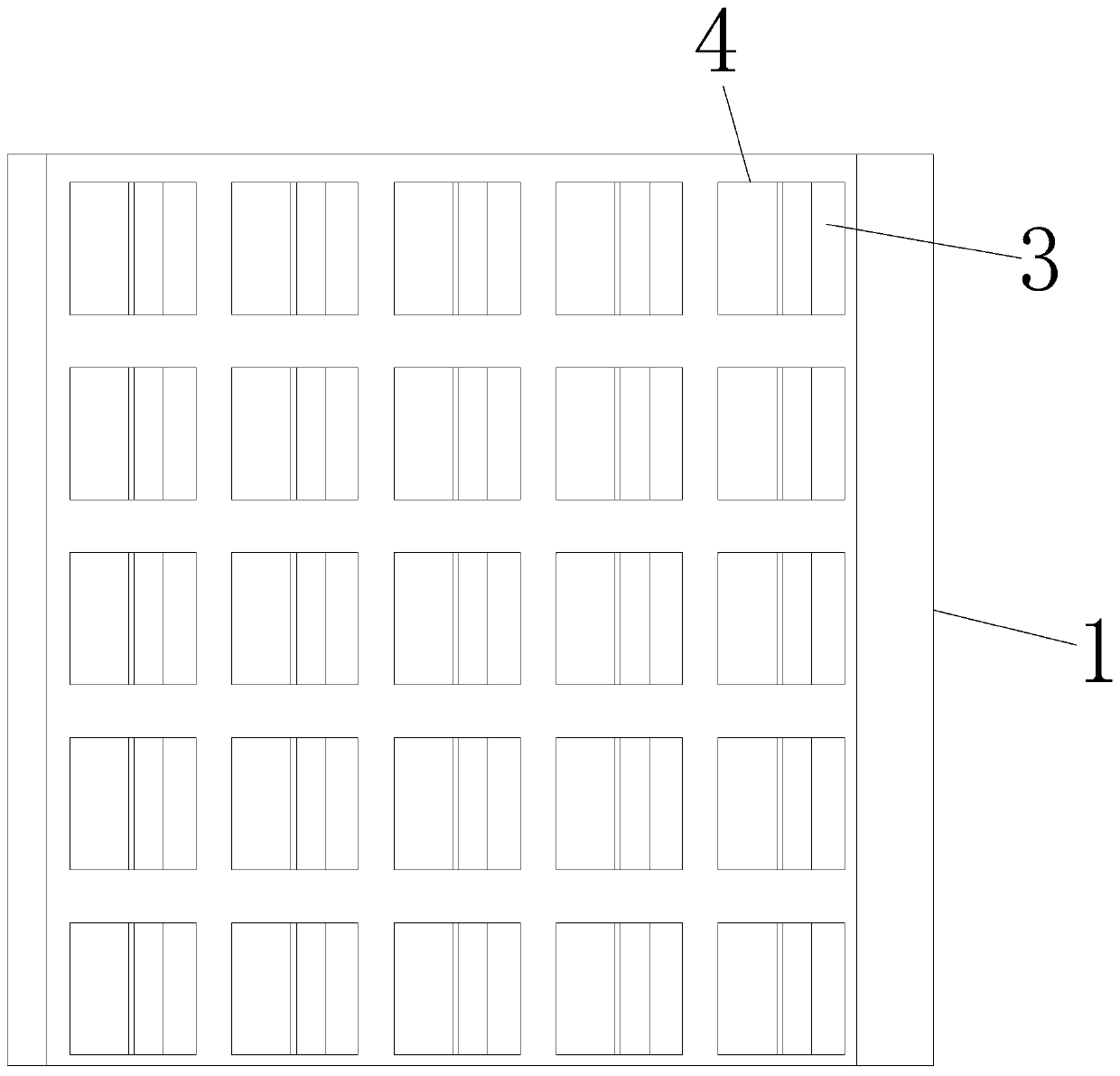

[0027] Example 1: Please refer to figure 1 and image 3 , a polyurethane mattress with internal airflow adjustment, comprising a lower plate 1 and an upper plate 2, the lower plate 1 is a polyurethane material plate with raised left and right ends, and the upper plate 2 is a polyurethane plate with a corrugated lower surface, so The upper surface of the lower plate 1 is provided with an extrusion circulation device 3, and a spring 5 is arranged on the side wall of the extrusion circulation device 3, and one end of the spring 5 is fixedly connected with the side wall of the extrusion circulation device 3, and the other end of the spring 5 is provided with an extrusion plate 4. The extrusion plate 4 is arranged obliquely along the wave inclination direction of the upper plate 2, and the spring 5 is fixedly connected to the extrusion plate 4. The number of the extrusion circulation devices 3 is 100 to 20 on the upper plate, and the extrusion circulation devices 3 is smaller than...

Embodiment 2

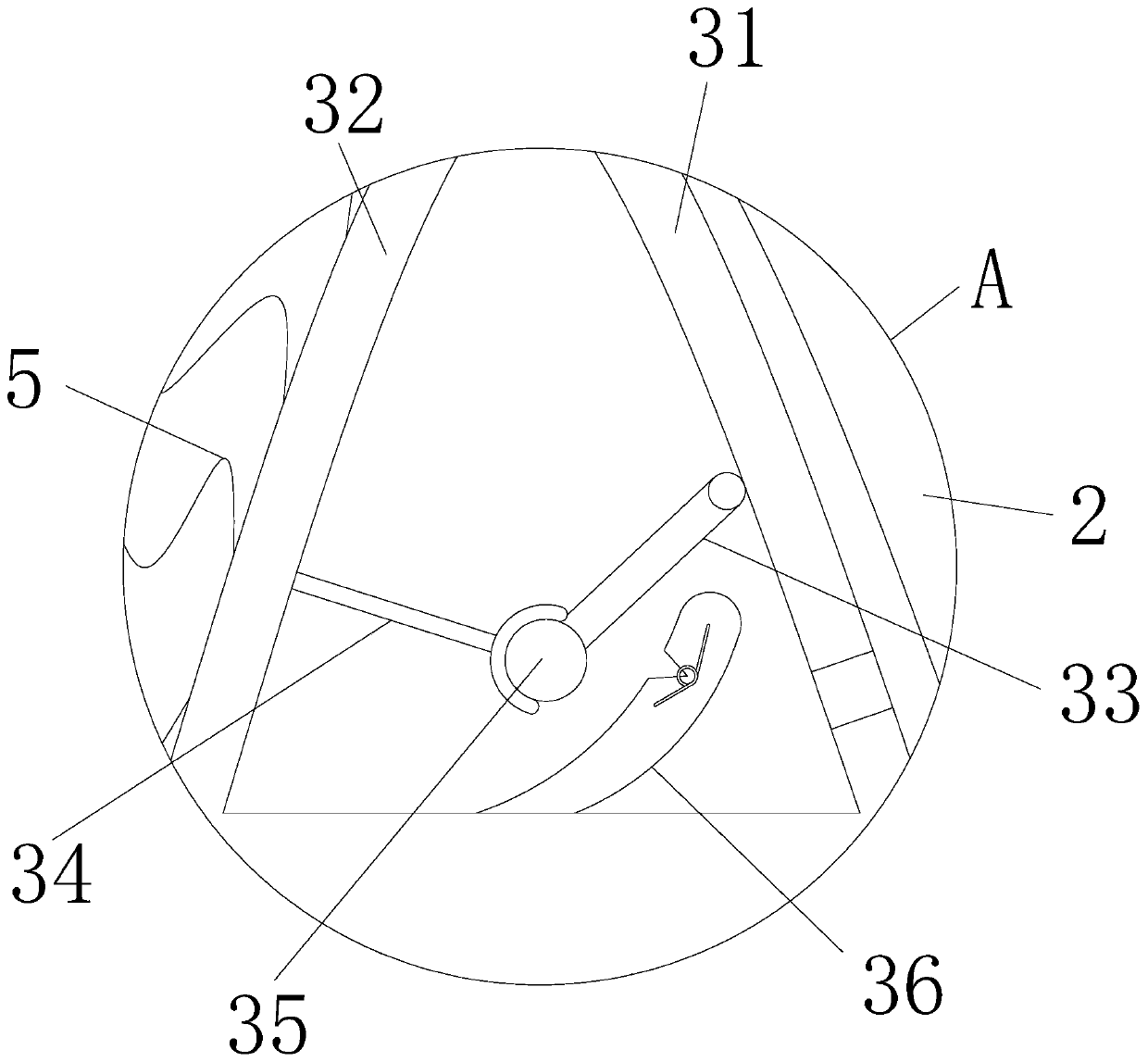

[0028] Embodiment 2: On the basis of Embodiment 1, please refer to figure 2 , the extrusion flow device 3 includes a fixed plate 31 and an elastic movable plate 32, fixedly connected between the fixed plate 31 and the elastic movable plate 32, and the spring 5 is arranged on the wall surface of the elastic movable plate 32 side, and the fixed plate 31 side An air outlet is opened through the wall, and the air outlet position on the fixed plate 31 is located at the bottom end of the side wall of the fixed plate 31, and a connecting rod 33 is arranged on the side wall of the fixed plate 31 near the elastic movable plate 32, and the connecting rod 33 It is installed on the side wall of the fixed plate 31 through the hinge, and the elastic movable plate 32 is provided with a catcher 34 on the side wall near the fixed plate 31. The catcher 34 is a combination, and specifically the catcher 34 consists of a mounting rod. It is composed of a semi-cylindrical shovel, and the mounting ...

Embodiment 3

[0029] Embodiment three: on the basis of embodiment two, please refer to figure 2 , the part of the upper surface of the lower plate 1 located in the extrusion flow device 3 is provided with a rebound arc plate 36, the front and rear length of the rebound arc plate 36 is the same as that of the clamping shaft 35, and the rebound arc plate 36 is fixedly installed on the lower On the upper surface of the board 1 , a torsion spring is arranged in the rebound arc plate 36 , and the rebound arc plate 36 is inclined to the direction of the connecting rod 33 , and the horizontal position of the uppermost end of the rebound arc plate 36 is higher than the clamping shaft 35 .

[0030]When in use, the user is located above the upper plate 2. At this time, the upper plate 2 will be squeezed, and the squeezed plate 4 at the squeezed position will also be squeezed synchronously. The kinetic energy transmission of the spring 5 will drive the extrusion flow. When the device 3 is squeezed sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com