Engineering road asphalt aggregate laying mechanism

A technology of road asphalt and aggregate, applied in the field of asphalt aggregate laying mechanism of engineering road, can solve the problem that asphalt is easy to produce harmful gas, damage the health of construction workers, etc., and achieve the effects of protecting health, slowing impact and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

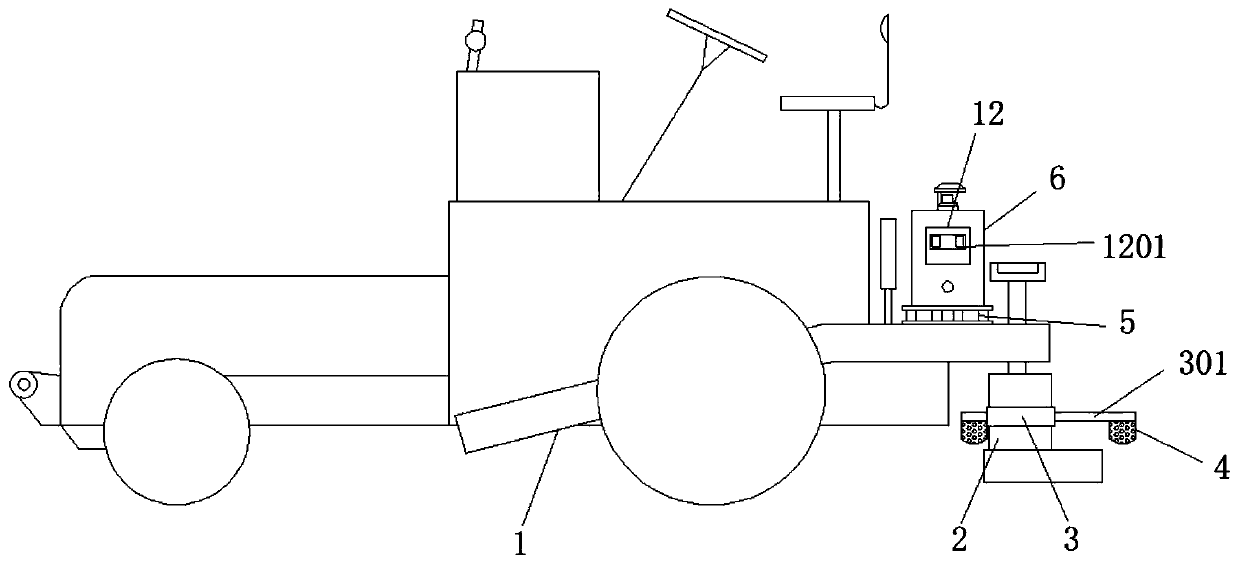

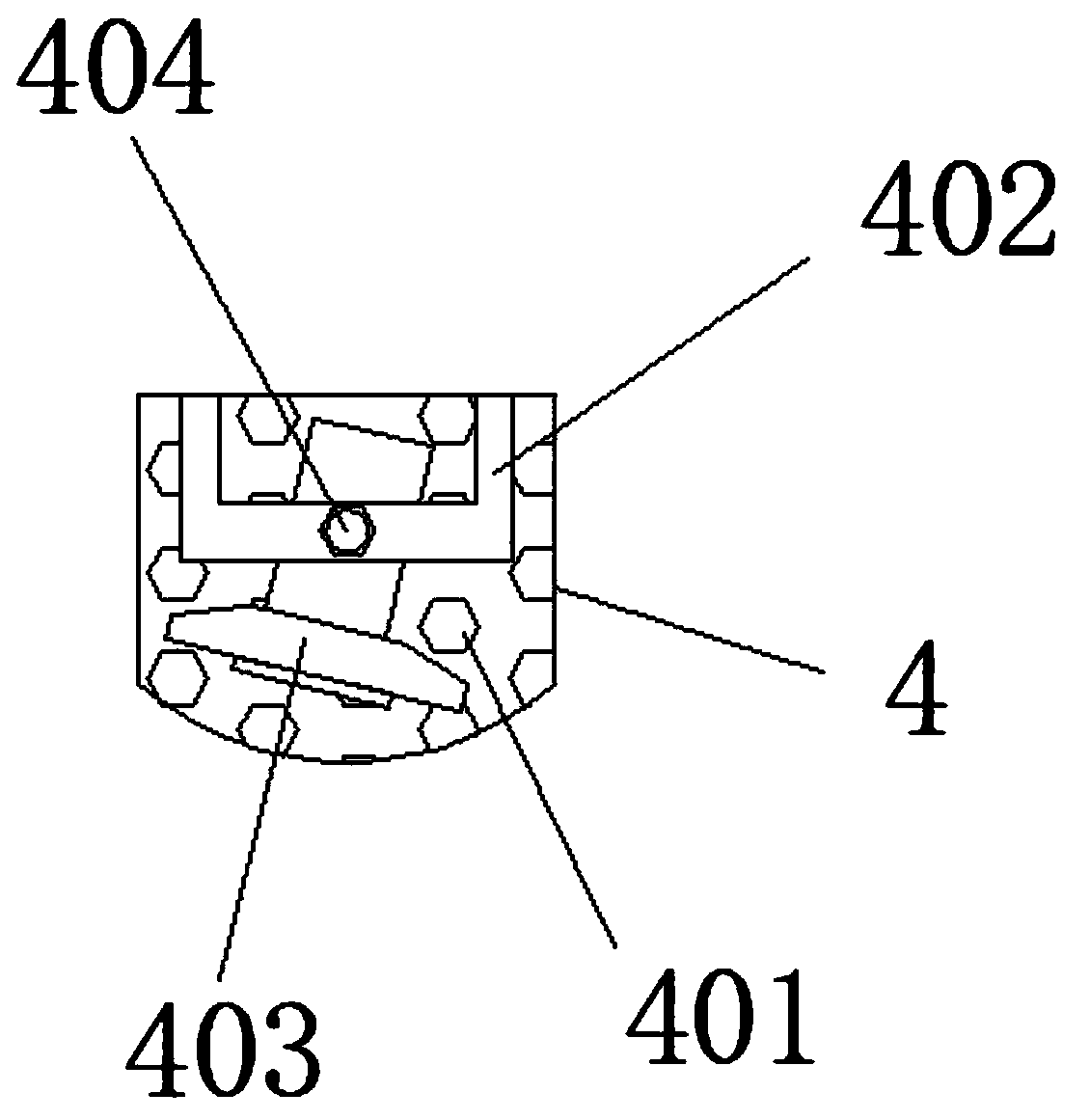

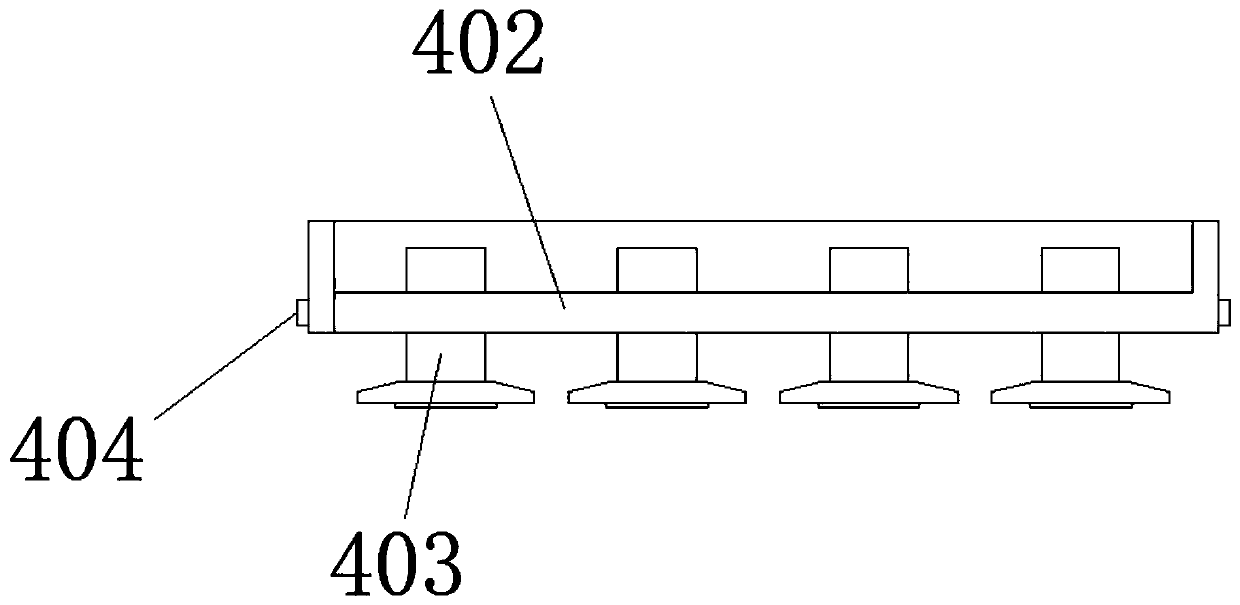

[0030] Such as Figure 1-7 As shown, the present invention provides a technical solution: a construction road asphalt aggregate laying mechanism, including a body 1 and a screed frame 2, the screed frame 2 is arranged on the right side of the body 1, and the surface of the screed frame 2 is A casing 3 is installed, and both sides of the casing 3 are provided with an air suction mechanism 4, and the air suction mechanism 4 is connected to the outer wall surface of the casing 3 through a bracket 301, and a shock absorbing mechanism 5 is installed on one side of the body 1 surface. A protective box 6 is installed on the top surface of the shock absorbing mechanism 5 , and a partition 601 is provided in the cavity of the protective box 6 .

[0031] The suction mechanism 4 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com