A spraying device for bamboo product processing

A technology for spraying devices and bamboo products, which is applied in the direction of spraying devices and liquid spraying devices, which can solve the problems of reduced quality of paper products, high labor intensity of operators, and uneven spraying of bamboo products, so as to reduce labor intensity and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

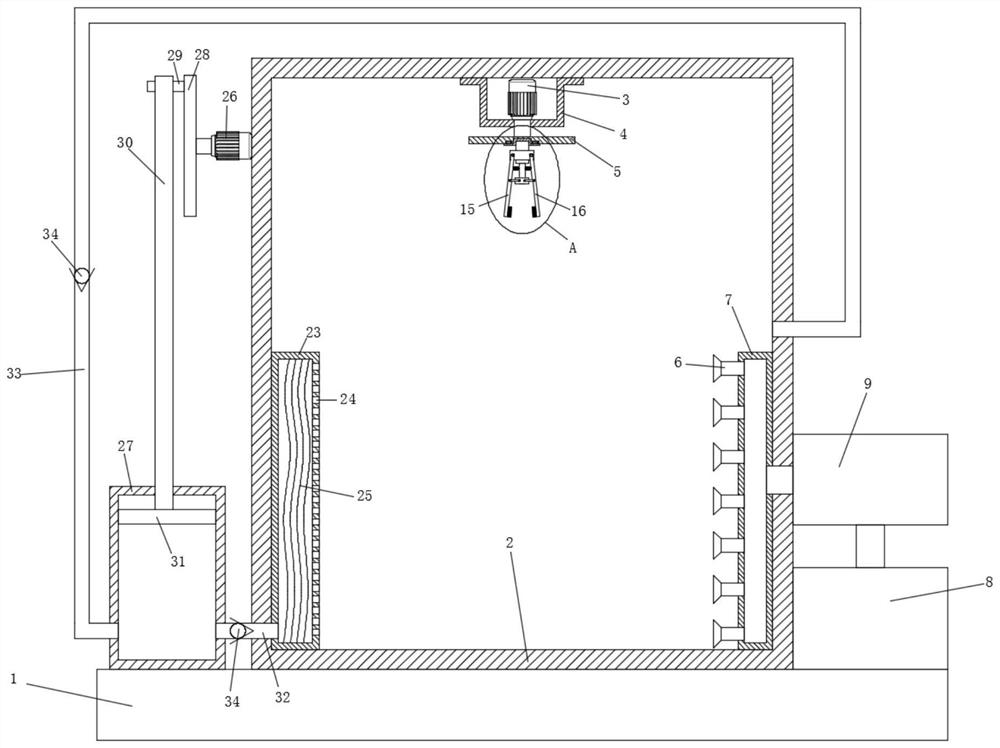

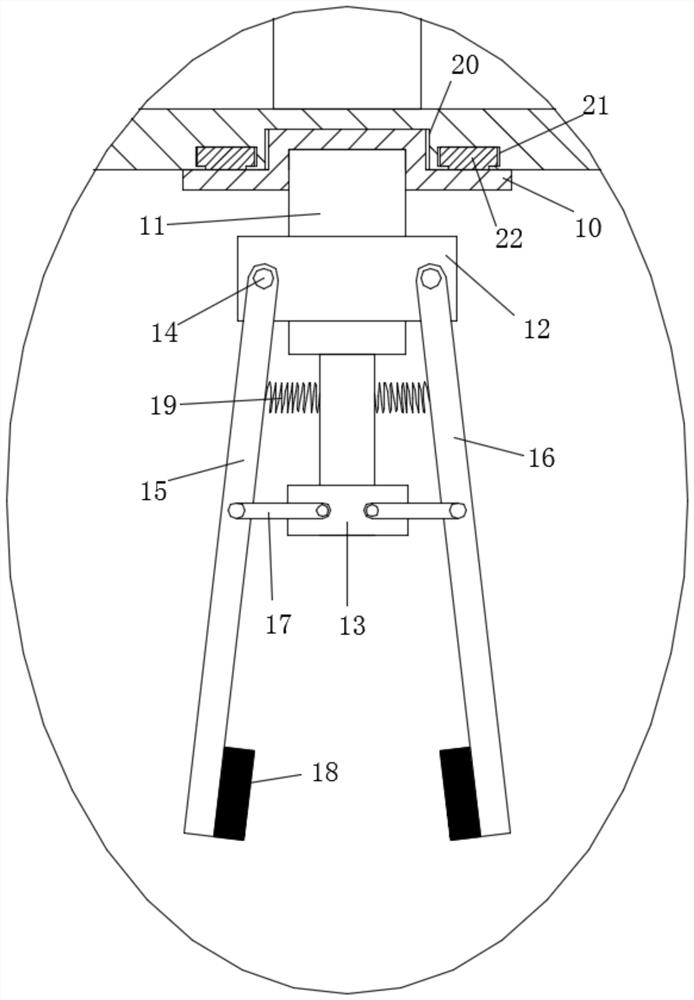

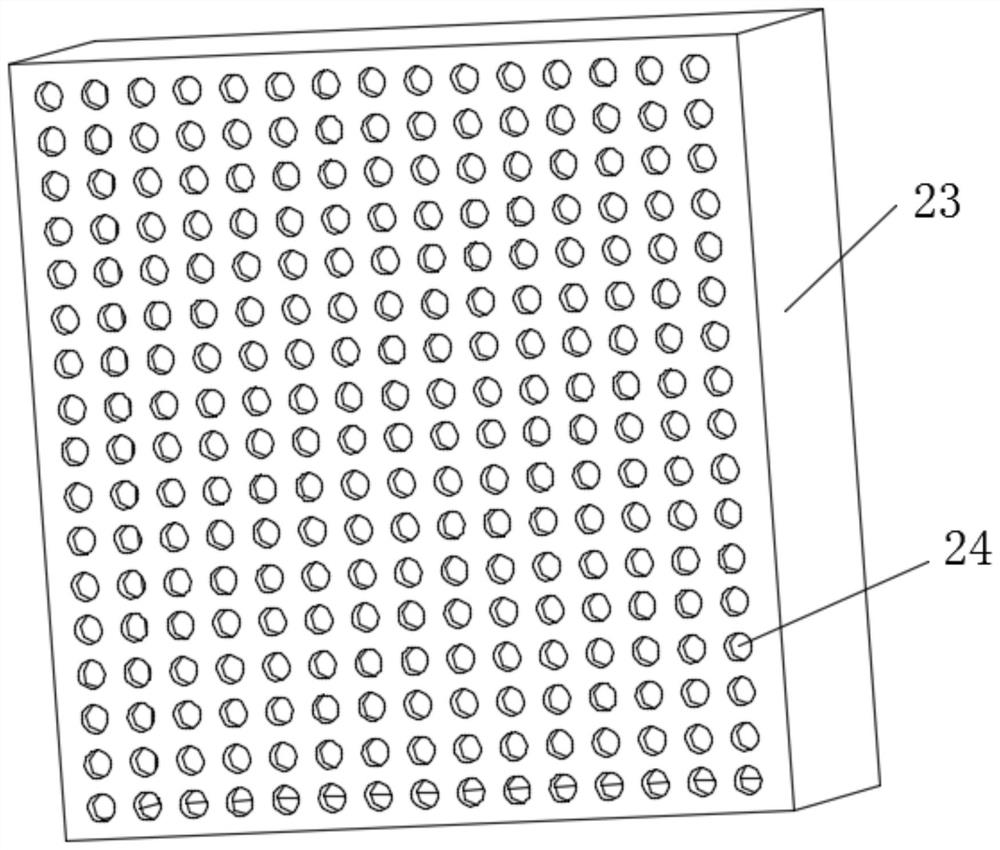

[0023] like Figure 1-3 , a spraying device for processing bamboo products, comprising a base 1, a mounting frame 2, a spraying device and a clamping device for fixing bamboo products, the mounting frame 2 is fixedly mounted on the base 1, the spraying device and the clamping The device is arranged in the installation frame 2, and the clamping device is provided with a power assembly for driving the clamping device to rotate, and the power assembly includes a drive motor 3 and a motor bracket 4 for fixedly installing the drive motor 3, the motor Support 4 is arranged on the top inner wall of installation frame 2, and the output end of described drive motor 3 is fixedly installed fixed plate 5, and described clamping device is arranged on the bottom of fixed plate 5; By setting drive motor 3, the bamboo product to be sprayed passes through The clamping device is in a fixed position, and the drive motor 3 rotates at a constant speed, which drives the clamping device to rotate at...

Embodiment 2

[0030] like Figure 4 , the present embodiment is further improved on the basis of Embodiment 1, the improvement is that: the inner wall of the side of the installation frame 2 is symmetrically provided with a lifting chute 35, and a lifting slider 38 is slidably installed in the lifting chute 35, The upper surface of the lifting slider 38 is fixedly installed with a symmetrically arranged second mount 39, the second mount 39 is fixedly mounted with an optical axis 40, and a symmetrically arranged moving slider 41 is slidably installed on the optical axis 40, The motor bracket 4 is fixedly installed on the bottom of the lifting slider 38, and a lifting assembly is arranged between the top of the installation frame 2 and the power assembly, and the lifting assembly includes a mounting block 36 fixedly installed on the inner wall of the top of the installation frame 2 and a lifting assembly. Motor 37, described mounting block 36 is arranged symmetrically, and described lifting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com